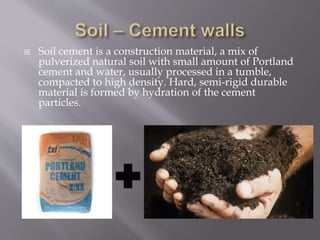

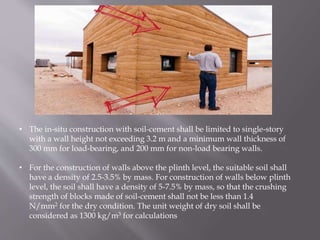

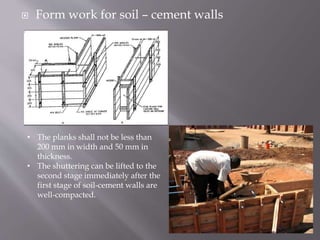

This document discusses the use of soil-cement as a construction material. Soil-cement is created by mixing pulverized natural soil with a small amount of Portland cement and water. This process forms a hard, semi-rigid and durable material through the hydration of cement particles. The document provides details on the composition of soil-cement, in-situ construction techniques for walls up to 3.2 meters in height using soil-cement, and curing and plastering requirements.