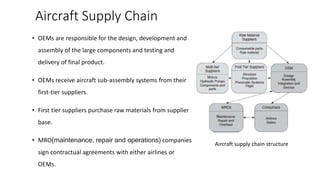

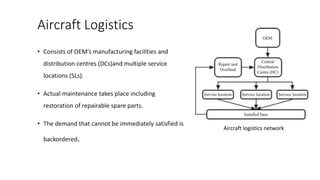

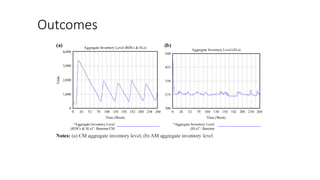

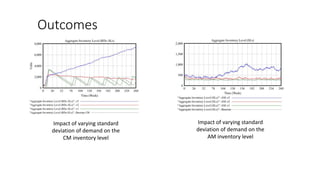

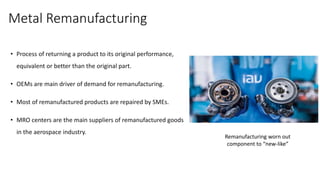

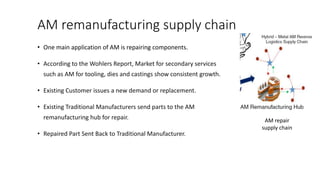

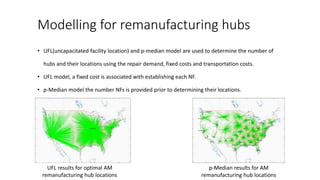

The document discusses the impact of additive manufacturing (AM) on the aircraft supply chain, emphasizing its role in enhancing supply chain performance and inventory management through system dynamics modeling. It highlights challenges faced by SMEs in accessing production-grade metal AM systems and the potential of integrating AM in remanufacturing processes. Additionally, it presents research on optimizing remanufacturing hub locations using facility location models and compares costs of AM methods in reverse logistics.