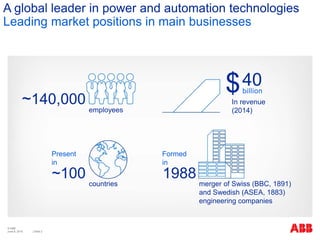

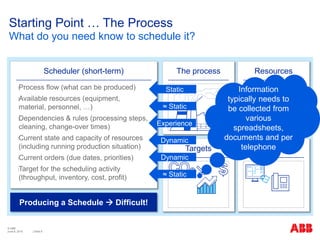

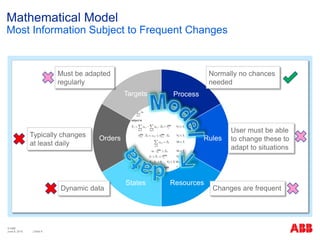

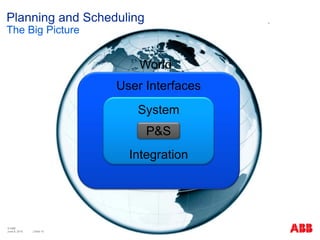

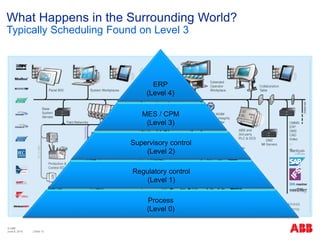

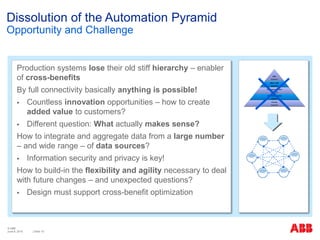

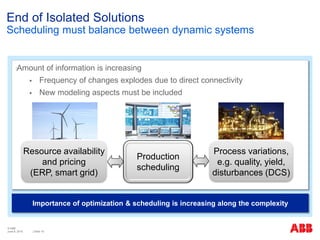

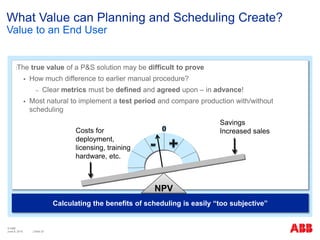

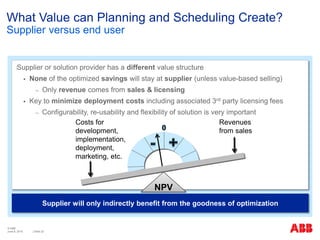

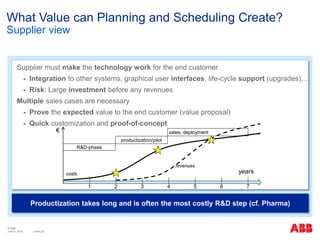

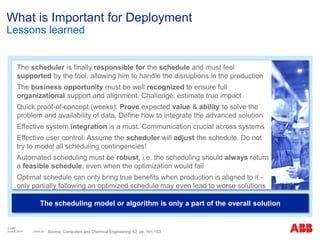

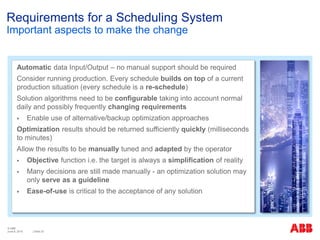

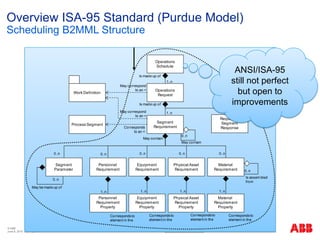

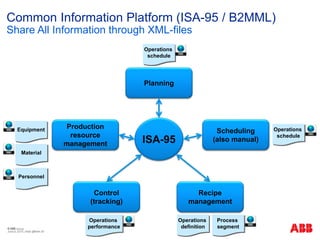

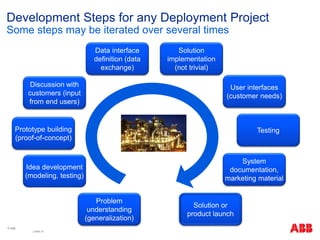

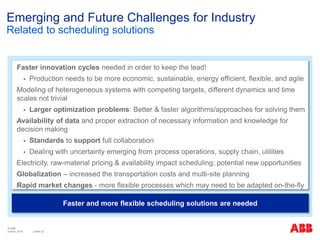

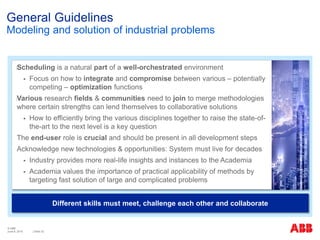

This document discusses scheduling solutions in industrial contexts. It provides an overview of ABB, a global leader in power and automation technologies. The document outlines key trends like big data, cloud computing, and the Internet of Things that are affecting production planning and scheduling. It also discusses challenges in deploying scheduling solutions and ensuring they provide value to both suppliers and end users. Effective system integration, quick proof-of-concept tests, and allowing manual adjustments are important lessons learned from previous implementations.