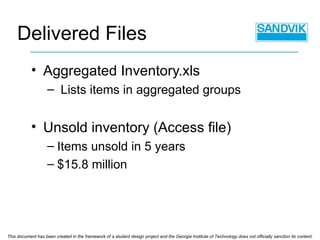

This document summarizes a student design project for a client company to optimize its warehouse network and inventory management. The project involved aggregating the client's inventory and customer data, developing a linear programming model to minimize costs while meeting service level targets, and analyzing the results to identify cost savings opportunities and make recommendations. The project was delivered through a final report and data files providing the model outputs and lists of obsolete inventory items.

![This document has been created in the framework of a student design project and the Georgia Institute of Technology does not officially sanction its content. Warehouse Network Design Saila Balasubramanian Ryan Bechtel Linh Nguyen Rigan Patel Brad Sims Brian Turner Advisor: Dr. Marc Goetschalckx Sponsor Contact: Mr. Stan Boddy Aftermarket Processes Manager – USA and Canada [email_address] (404) 589-3861 December 5, 2008](https://image.slidesharecdn.com/SandvikMiningandConstructionFinalPresentationClientVersion-123093682923-phpapp03/85/Sandvik-Mining-And-Construction-Final-Presentation-1-320.jpg)

![Minimize Σ [(7%)(# of Items)(Item Value) (Stock Level) ] # of items in each item group Average value of each item group Stock level decision variable Σ [(# of Customers)(# of Items)(Shipping Cost) (% Demand Allocated) ] # of Customers in each customer zone # of items in each item group Cost to ship from warehouse to customer Demand allocation decision variable Objective function This document has been created in the framework of a student design project and the Georgia Institute of Technology does not officially sanction its content.](https://image.slidesharecdn.com/SandvikMiningandConstructionFinalPresentationClientVersion-123093682923-phpapp03/85/Sandvik-Mining-And-Construction-Final-Presentation-20-320.jpg)