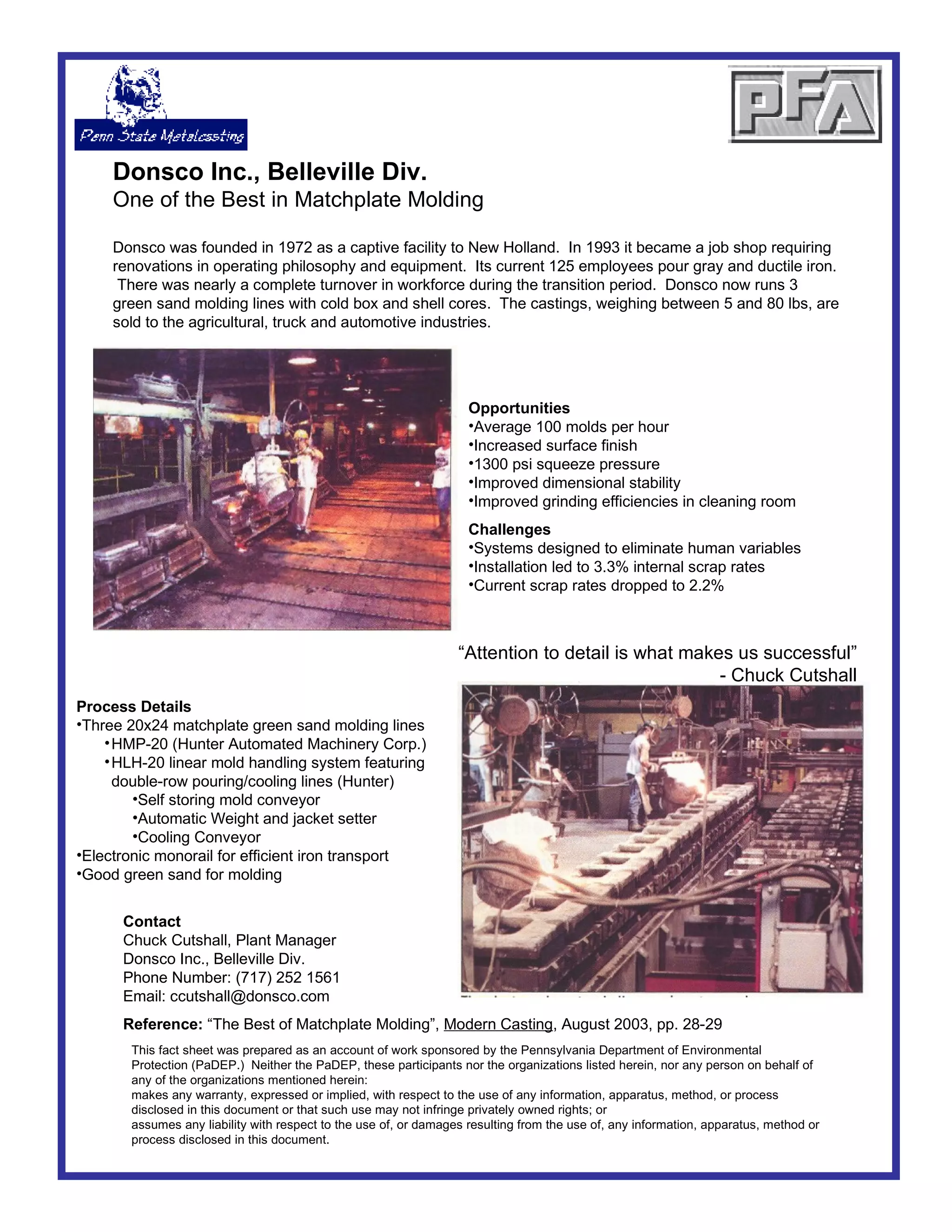

This document provides information about Donsco Inc., a company that specializes in matchplate molding. It produces castings weighing between 5 and 80 lbs for the agricultural, truck, and automotive industries using three green sand molding lines. The document outlines opportunities like increased production and improved quality, as well as challenges faced and details of the matchplate molding process used.