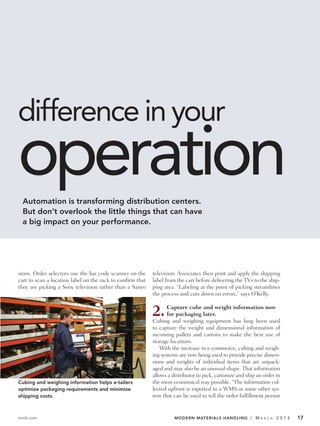

Automation is transforming distribution centers, but small improvements can also make a big impact on performance. This issue of Modern Materials Handling focuses on such "little things" as powered mobile workstations, capturing product details early, centralized packing, dock equipment, and streamlined loading/unloading. It also examines how carts and casters have evolved from unwieldy to optimized for mobility and flexibility. Finally, inventory management experts provide tips on basic strategies that some operations may have neglected during technology adoption.