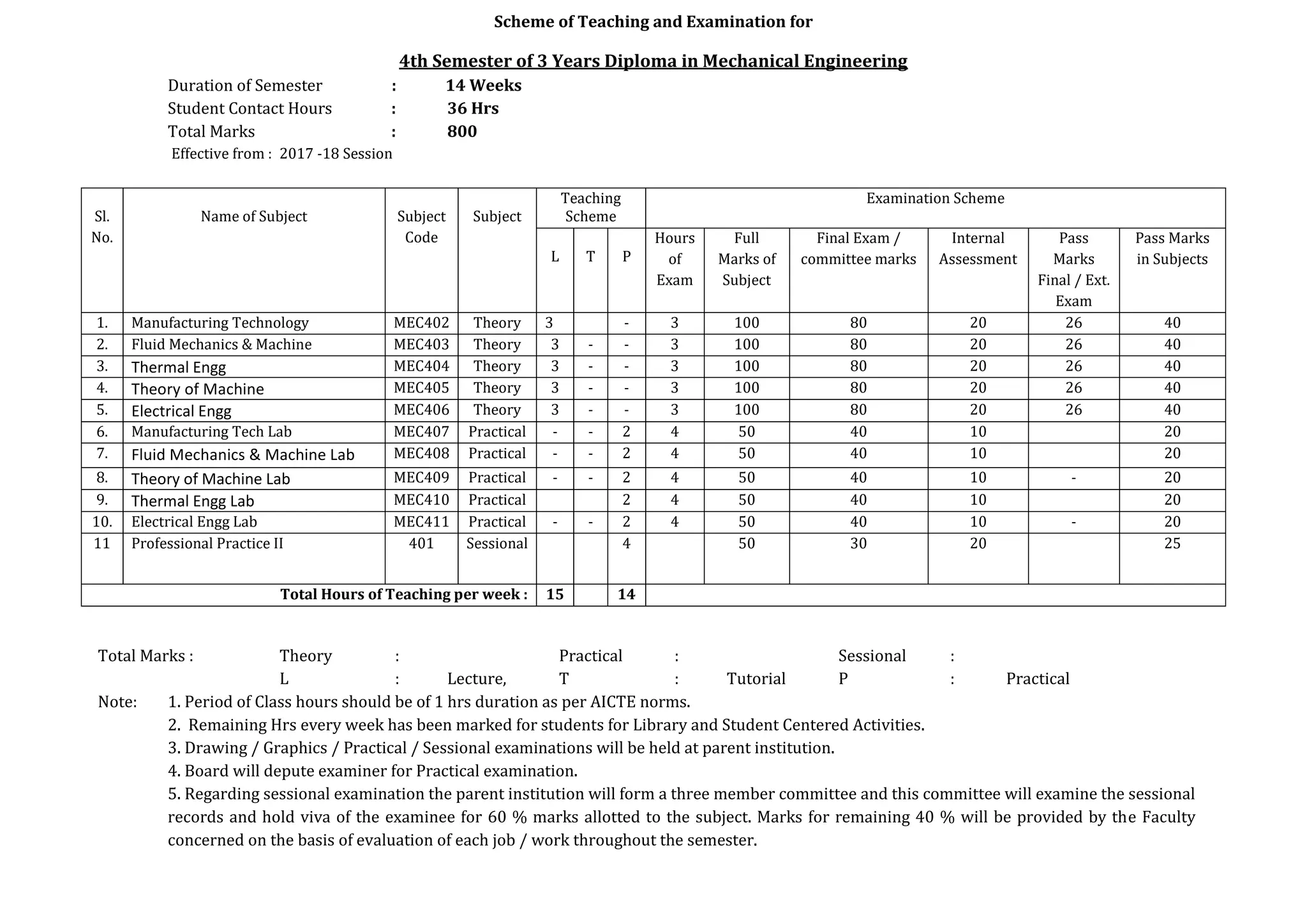

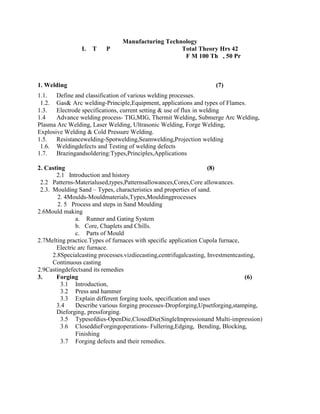

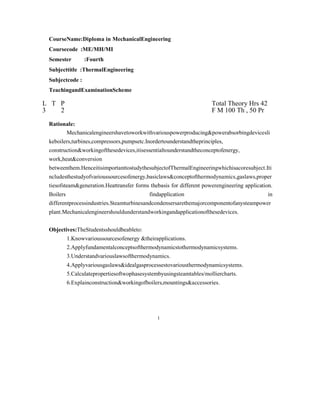

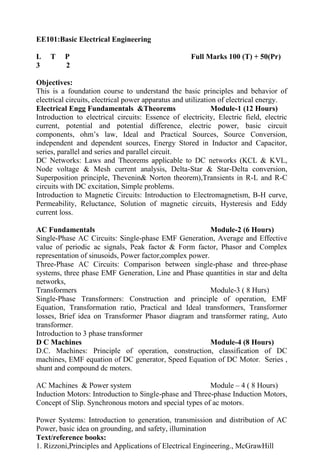

The document provides details of the 4th semester scheme of teaching and examination for a 3 year diploma in mechanical engineering. It includes information on the duration of the semester, total student contact hours, total marks distribution, subjects to be taught, teaching scheme for each subject including theory and practical hours as well as examination scheme with marks distribution. It also provides the pass marks criteria for final and internal assessment. Subject details are given for manufacturing technology, fluid mechanics and machine, thermal engineering, theory of machines, electrical engineering and other related lab and practical subjects. Recommended books, list of practical sessions and content breakdown are also included for some subjects.