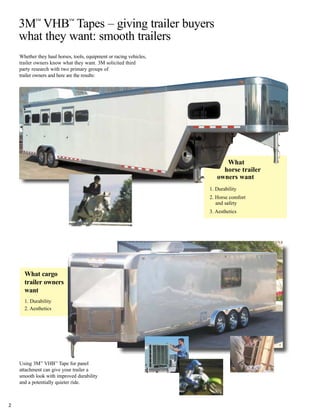

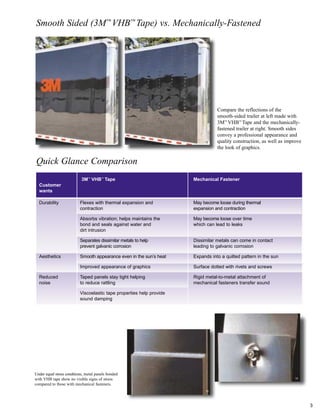

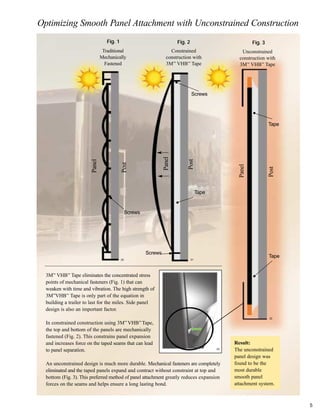

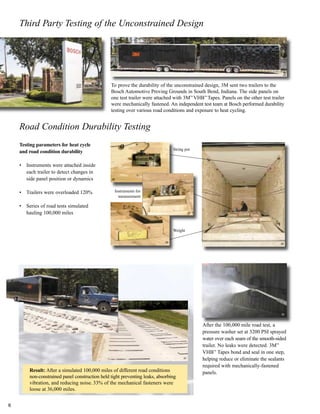

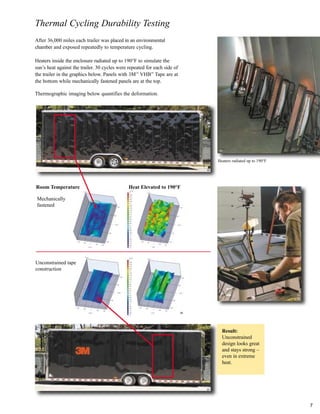

3M conducted research that found trailer owners prioritize durability, aesthetics, and horse/cargo safety. 3M's VHBTM tapes were tested and found to provide a smooth appearance while withstanding extreme heat, vibration, and water pressure testing better than mechanically fastened panels. An independent test showed trailers assembled with VHBTM tapes were up to 41% quieter and had up to 30% less vibration than mechanically fastened trailers, which could benefit horse comfort during transport.