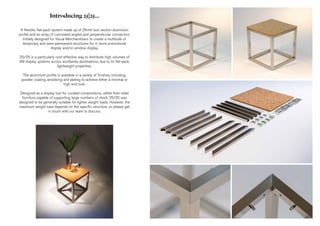

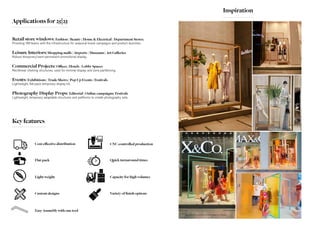

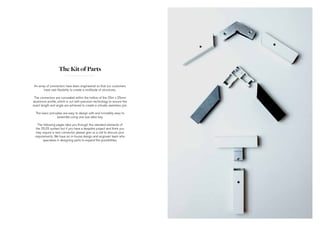

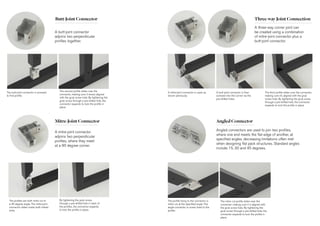

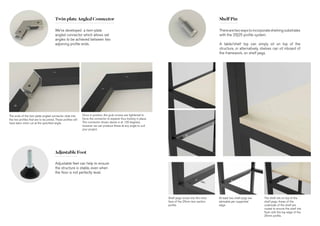

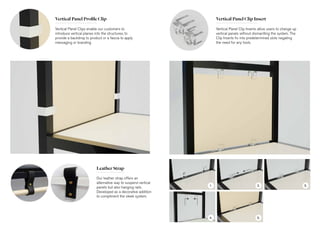

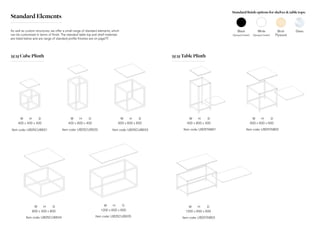

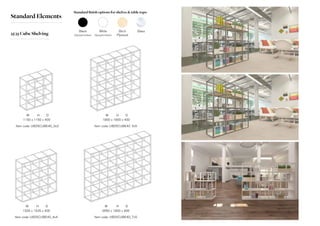

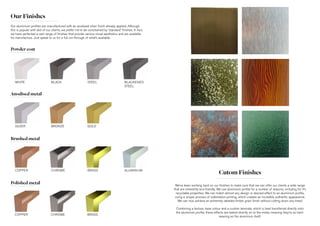

The document describes the 25|25 visual merchandising system, which is a lightweight, flat-pack system made of aluminum for promotional displays. It consists of aluminum profiles and concealed connectors that allow for flexible and easy assembly. The system is cost-effective for shipping worldwide due to its flat-pack design. It is intended to be used for visual merchandising and retail displays rather than supporting heavy loads. The document provides details on the system's kit of parts, applications, and finish options.