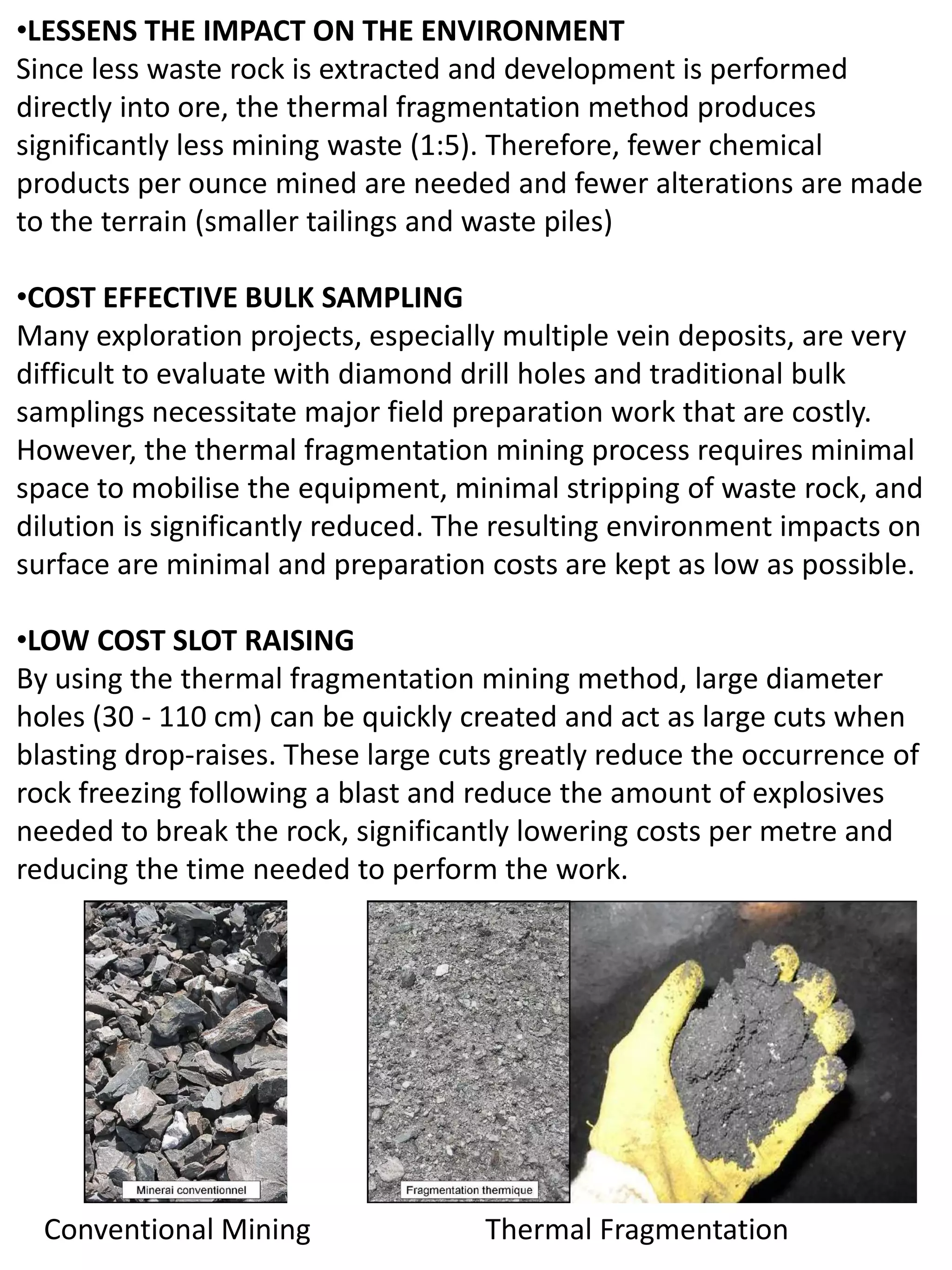

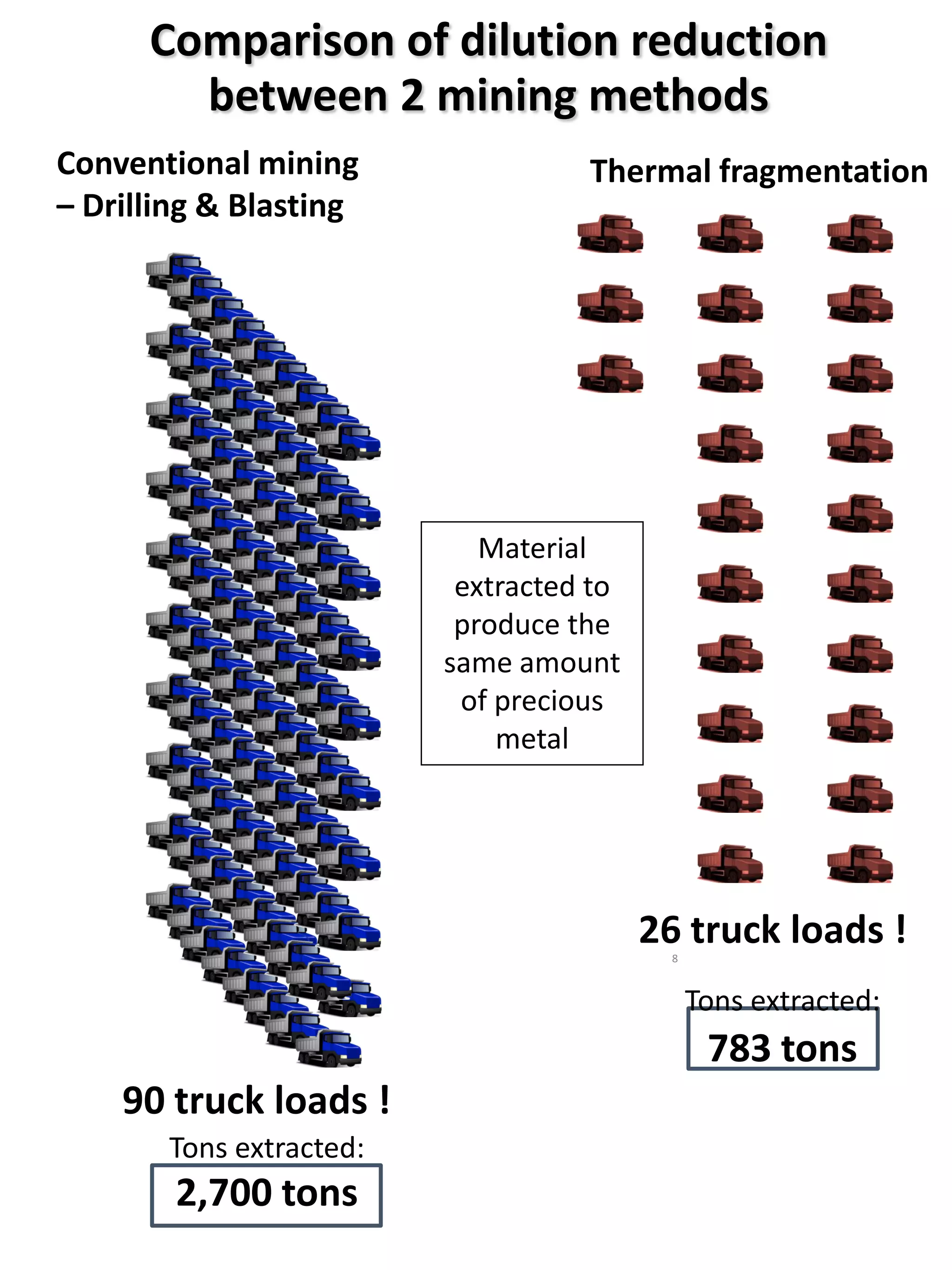

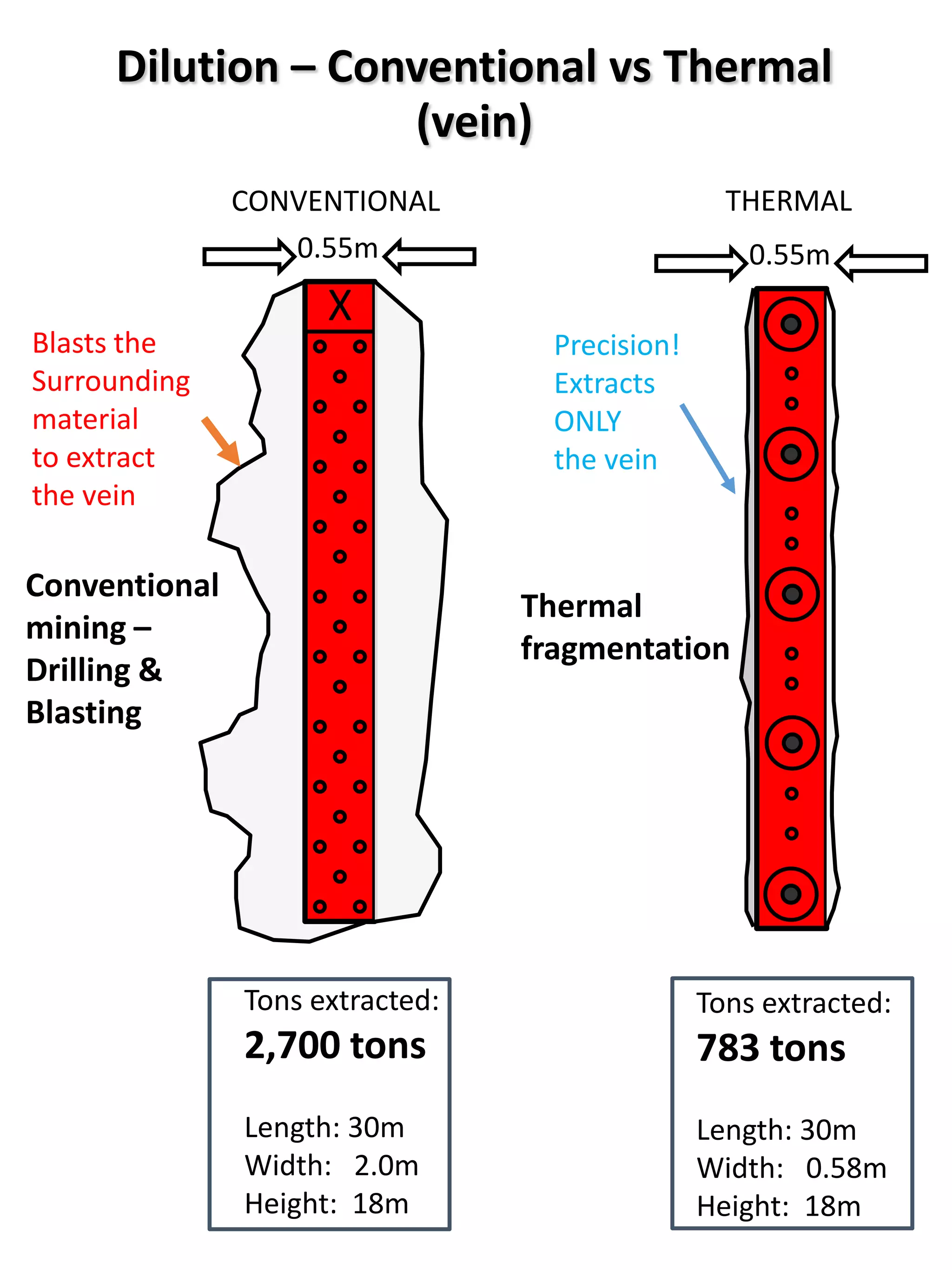

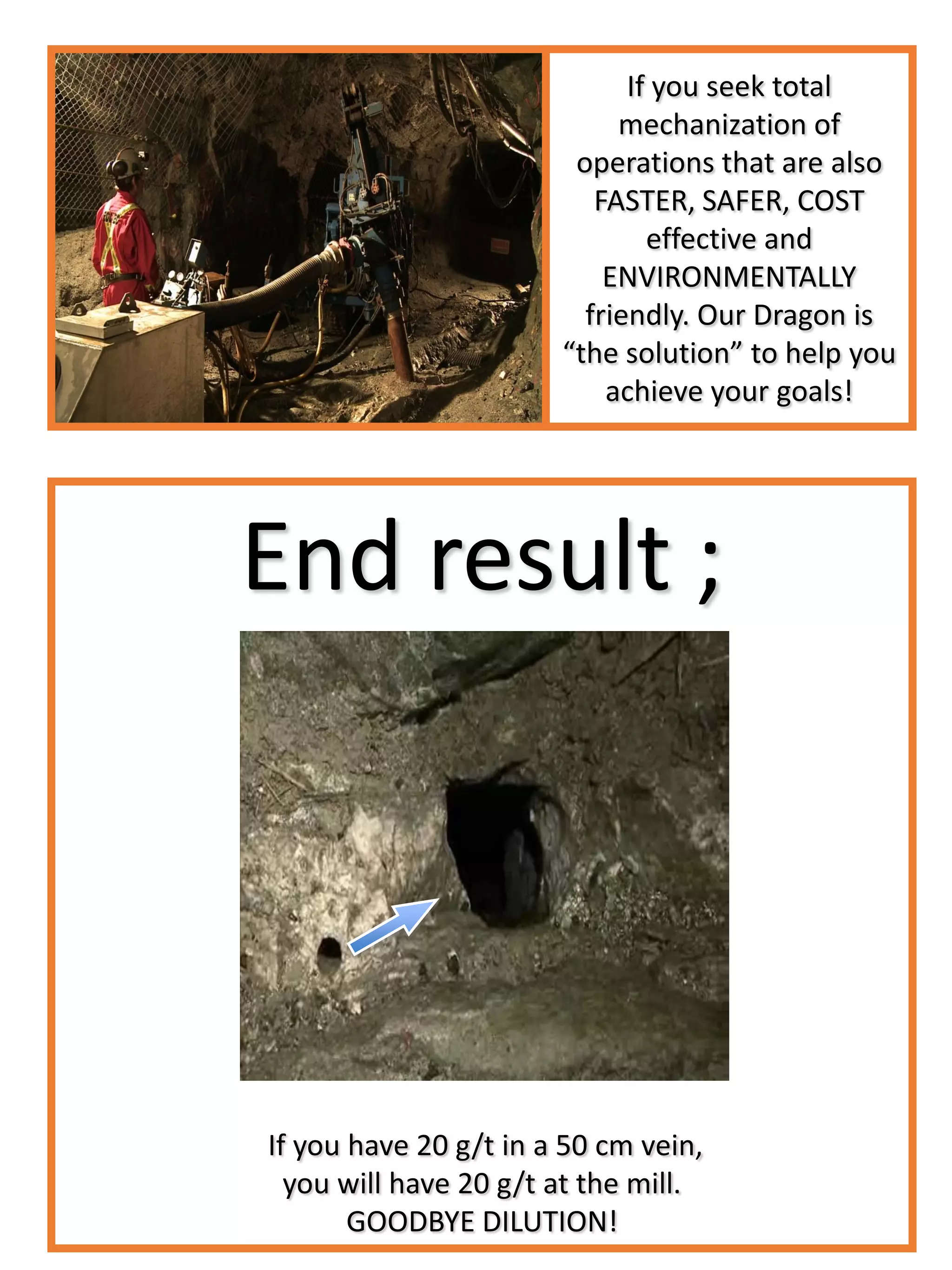

Thermal fragmentation is an innovative mining method that is more efficient, productive, and environmentally friendly compared to conventional drilling and blasting. It can extract narrow ore bodies profitably by greatly reducing dilution. This precision mining method is fully mechanized, extends mine life, improves safety, and lowers costs by reducing waste. It has the potential to help mining companies remain profitable by accessing reserves that conventional methods cannot.