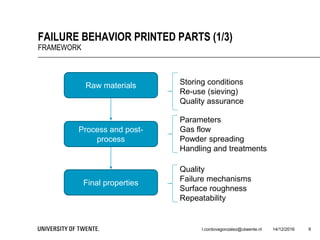

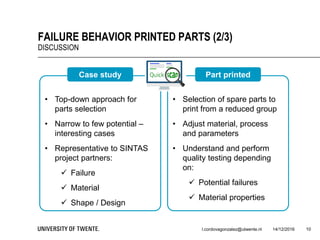

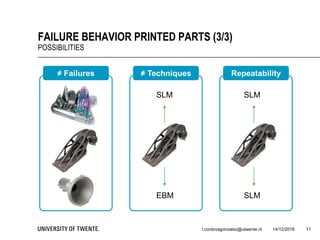

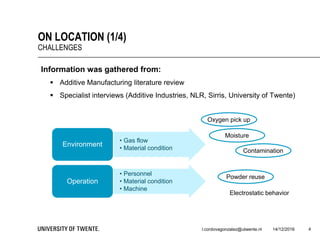

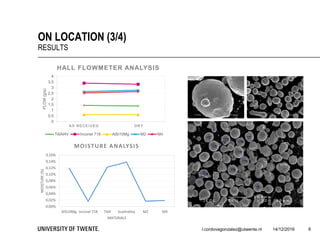

This progress update summarizes work on package 1 which focuses on raw material conditions and failure behavior of printed parts. Regarding location, challenges of gas flow, moisture, contamination and their impact on process, supply chain and costs were analyzed. Results showed varying moisture levels and powder flow rates for different materials. Next steps are to identify effects on builds and mechanical properties. The framework presented examines failure mechanisms from raw materials through final properties. A top-down approach to select case studies of representative parts from partners will be used to understand and test for quality and potential failures under different materials and processes.

![5

ON LOCATION (2/4)

IMPACT

l.cordovagonzalez@utwente.nl 14/12/2016

How raw materials condition is linked with the process and supply

chain:

Environment (moisture, contamination)

Storage conditions (time, containers, ambient)

Supply (frequency, supplier, transportation, quality)

Operation (powder reuse)

Cost (quality vs. price?)

Sustainability (energy & resources consumption)

Supply (frequency, quality)

[1] http://www.3dprinterworld.com/

Rapid Prototyping labs in Afghanistan

and Fort Belvoir, USA [1]](https://image.slidesharecdn.com/161130progressupdatewp1-161214145854/85/161130-Progress-Update-WP1-Laura-Cordova-Gonzalez-5-320.jpg)

![14/12/2016

[2] Aboulkhair, Nesma T. (2016) Additive manufacture of an aluminium alloy: processing, microstructure, and mechanical

properties. PhD thesis, University of Nottingham.

7

ON LOCATION (4/4)

WRAP-UP

Various parameters have effect on

process and powder properties.

The aim of the research is to identify

the most relevant ones and quantify its

influence.

Next steps are identifying the effects in

AM builds and testing its influence on

the mechanical properties.

Evolution of pores with various scan speed [2]](https://image.slidesharecdn.com/161130progressupdatewp1-161214145854/85/161130-Progress-Update-WP1-Laura-Cordova-Gonzalez-7-320.jpg)