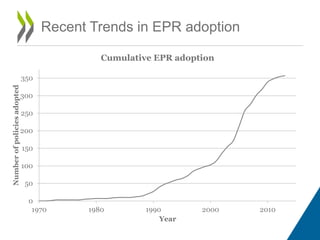

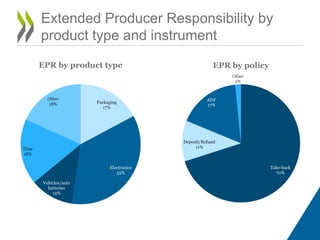

This document discusses extended producer responsibility (EPR), which shifts responsibility for end-of-life products upstream to producers. EPR aims to incentivize producers to design products with the environment in mind. The document outlines EPR goals, policy instruments like take-back and recycling targets, and how they apply across a product's life cycle. It summarizes 2001 OECD guidance on EPR and trends since like increased adoption and emerging issues. The objectives of this Global Forum are to take stock of recent EPR experiences, identify challenges, and begin updating guidance to address waste prevention and eco-design.