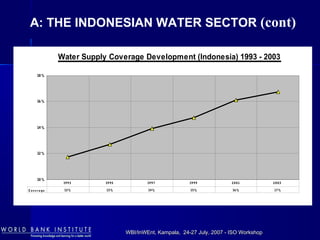

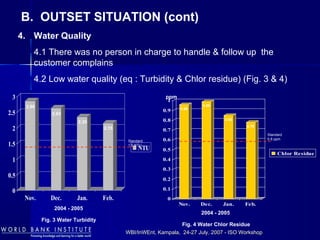

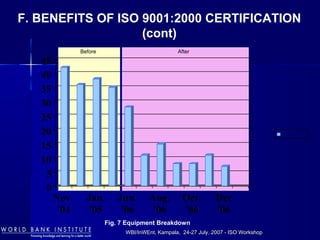

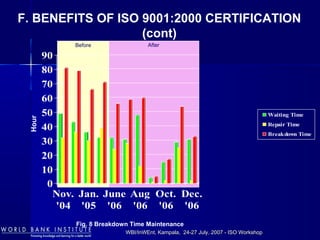

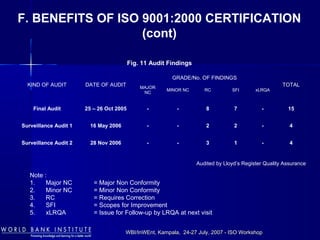

This document discusses the Indonesian experiences with ISO 9001:2000 certification of public water utility services. It provides an overview of the Indonesian water sector and the outset situation of poor service quality and infrastructure issues faced by many utilities. It then details the objectives of seeking ISO certification to improve performance, the scope and process of certification for one utility's water treatment plant, and the problems encountered and success factors. Benefits included reduced equipment breakdowns, lower maintenance times, and improved customer satisfaction through better service quality.