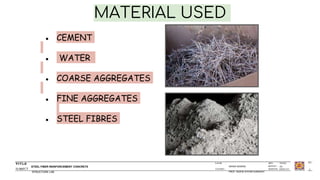

Steel fiber reinforced concrete is produced by adding short discrete steel fibers uniformly throughout concrete. This improves tensile and flexural strength compared to plain concrete. Steel fibers are added in small percentages between 0.3-2.5% by volume. Producing SFRC requires careful mixing to avoid balling and ensure uniform fiber distribution. Properties of SFRC depend on fiber shape, size, volume, and distribution. Applications include overlays, pavements, precast products, and structures requiring impact and crack resistance. Testing of steel fiber reinforced concrete produced cubes and beams to evaluate its properties.