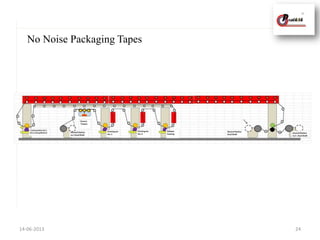

The document describes various coating and converting machine designs offered by Prathith Consultants for applications such as adhesive coating, breathable barrier coating on nonwoven fabrics, split leather manufacturing, insulation tape manufacturing, surgical tape manufacturing, spray coating and lamination for foam conversion, paper saturation, and packaging tapes. It provides details on coating methods, challenges, parameters, and passes for different machine designs along with photos and contact information.