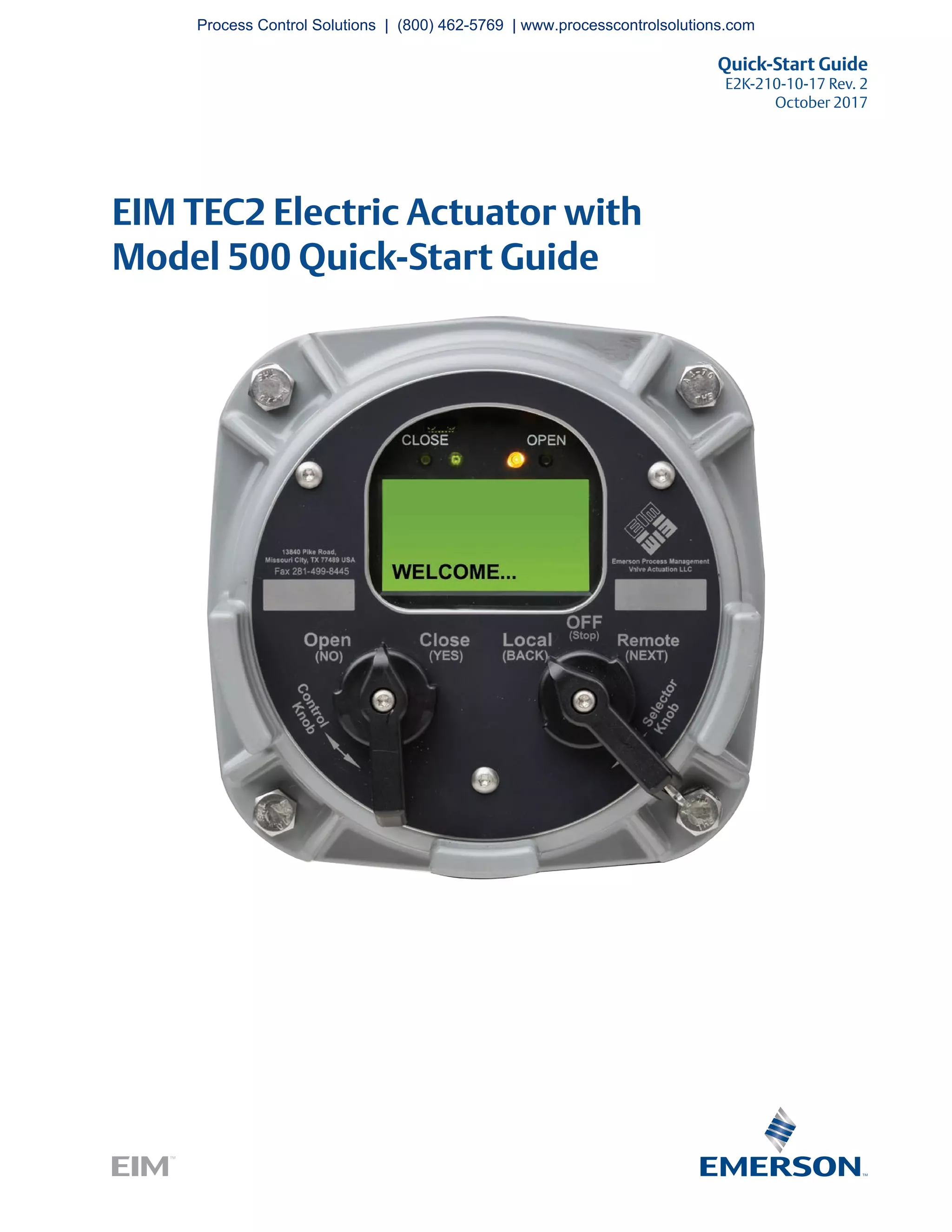

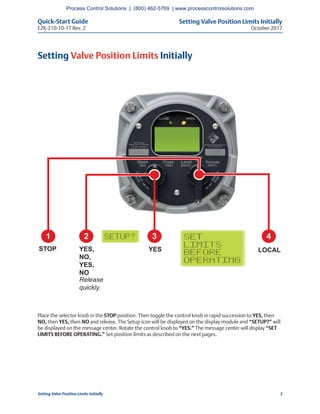

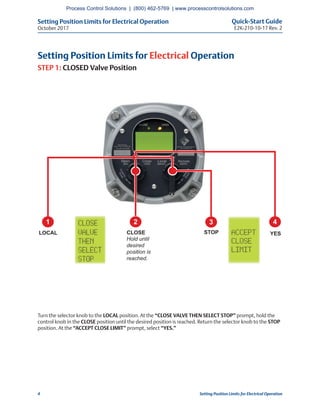

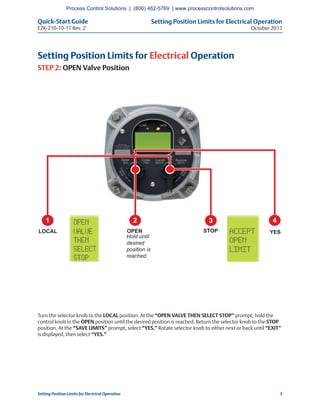

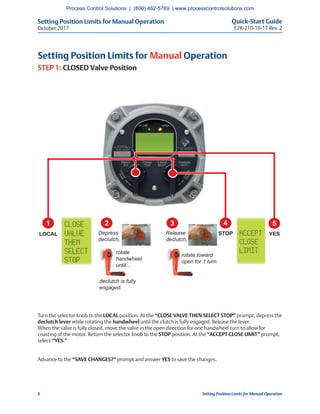

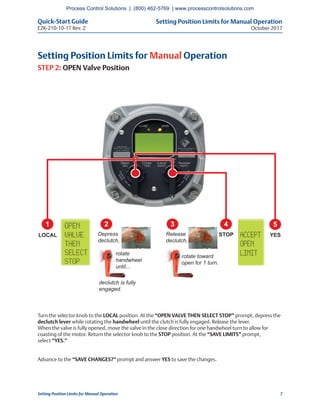

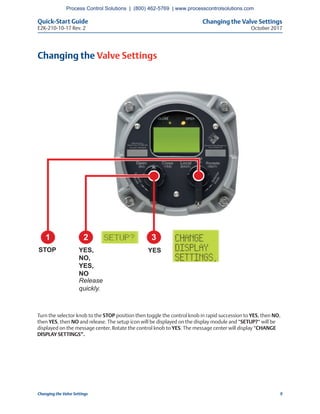

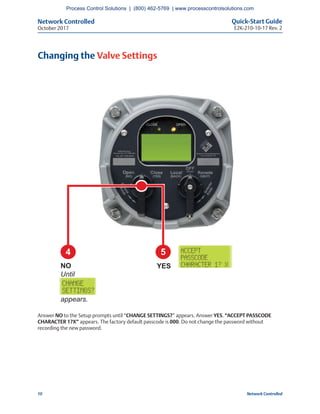

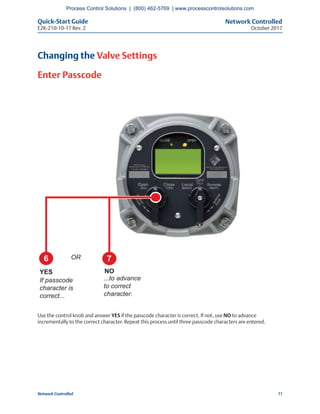

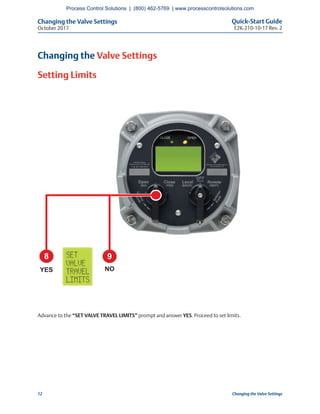

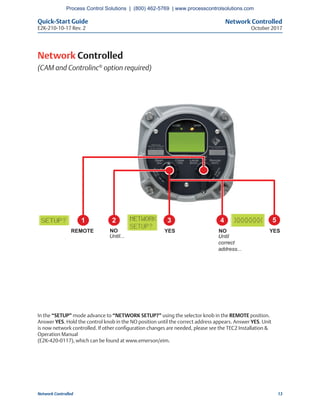

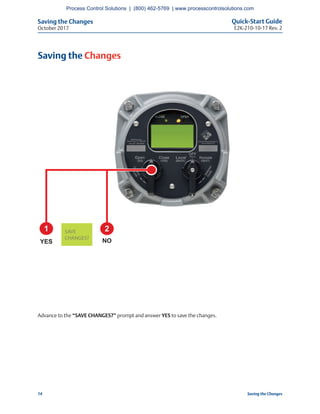

The quick-start guide provides instructions for setting up and configuring an EIM TEC2 electric actuator with a model 500. It describes how to power on the actuator, set the initial position limits for electrical or manual operation, check the open and closed settings, change valve settings like display configuration, and set the network address if using network control. The guide walks through each step using images and text to ensure the actuator is ready for normal operation.