Report

Share

Download to read offline

Recommended

More Related Content

Viewers also liked

Viewers also liked (8)

Similar to Dqm r a irwin factory

Similar to Dqm r a irwin factory (20)

2015 11-19-energy efficiency efficient use of raw materials

2015 11-19-energy efficiency efficient use of raw materials

Development of a Small-Scale Meat Dryer with Automated Dual Heating System

Development of a Small-Scale Meat Dryer with Automated Dual Heating System

Performance Evaluation of a Developed Multipurpose Solar Dryer

Performance Evaluation of a Developed Multipurpose Solar Dryer

Design and Development of Humidity Controller for Prevention of Microbiologic...

Design and Development of Humidity Controller for Prevention of Microbiologic...

Presentation on process, pollution and control in textile industry

Presentation on process, pollution and control in textile industry

IRJET- Performance Analysis of Evacuated Tube Solar Dryer with Desiccant Dehu...

IRJET- Performance Analysis of Evacuated Tube Solar Dryer with Desiccant Dehu...

IRJET- Design & Construction of Solar Dryer for Mango Slices

IRJET- Design & Construction of Solar Dryer for Mango Slices

Make wood residue into fuel pellets for plywood factory

Make wood residue into fuel pellets for plywood factory

More from DQM Solutions Ltd

More from DQM Solutions Ltd (7)

Dqm r a irwin factory

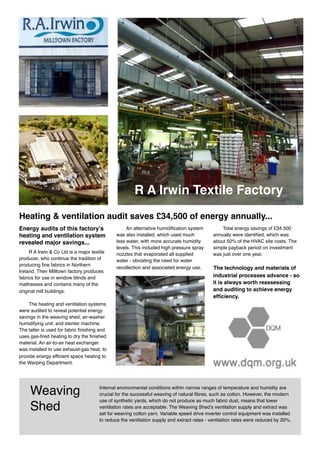

- 1. Internal environmental conditions within narrow ranges of temperature and humidity are crucial for the successful weaving of natural fibres, such as cotton. However, the modern use of synthetic yards, which do not produce as much fabric dust, means that lower ventilation rates are acceptable. The Weaving Shed’s ventilation supply and extract was set for weaving cotton yarn. Variable speed drive inverter control equipment was installed to reduce the ventilation supply and extract rates - ventilation rates were reduced by 20%. Weaving Shed Heating & ventilation audit saves £34,500 of energy annually... Energy audits of this factory’s heating and ventilation system revealed major savings... R A Irwin & Co Ltd is a major textile producer, who continue the tradition of producing fine fabrics in Northern Ireland. Their Milltown factory produces fabrics for use in window blinds and mattresses and contains many of the original mill buildings. The heating and ventilation systems were audited to reveal potential energy savings in the weaving shed; air-washer humidifying unit; and stenter machine. The latter is used for fabric finishing and uses gas-fired heating to dry the finished material. An air-to-air heat exchanger was installed to use exhaust-gas heat, to provide energy efficient space heating to the Warping Department. An alternative humidification system was also installed, which used much less water, with more accurate humidity levels. This included high pressure spray nozzles that evaporated all supplied water - obviating the need for water recollection and associated energy use. Total energy savings of £34.500 annually were identified, which was about 50% of the HVAC site costs. The simple payback period on investment was just over one year. The technology and materials of industrial processes advance - so it is always worth reassessing and auditing to achieve energy efficiency. R A Irwin Textile Factory