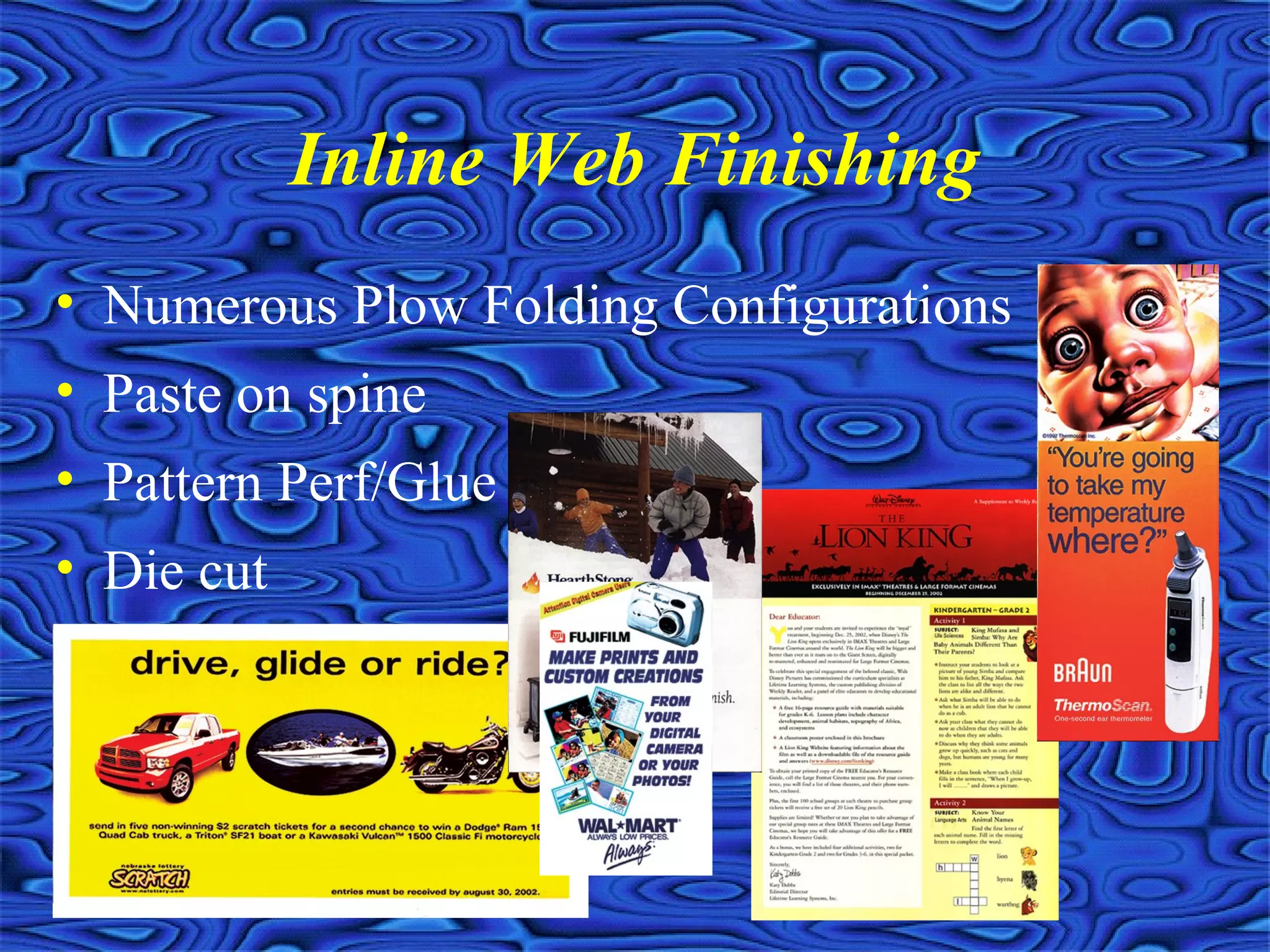

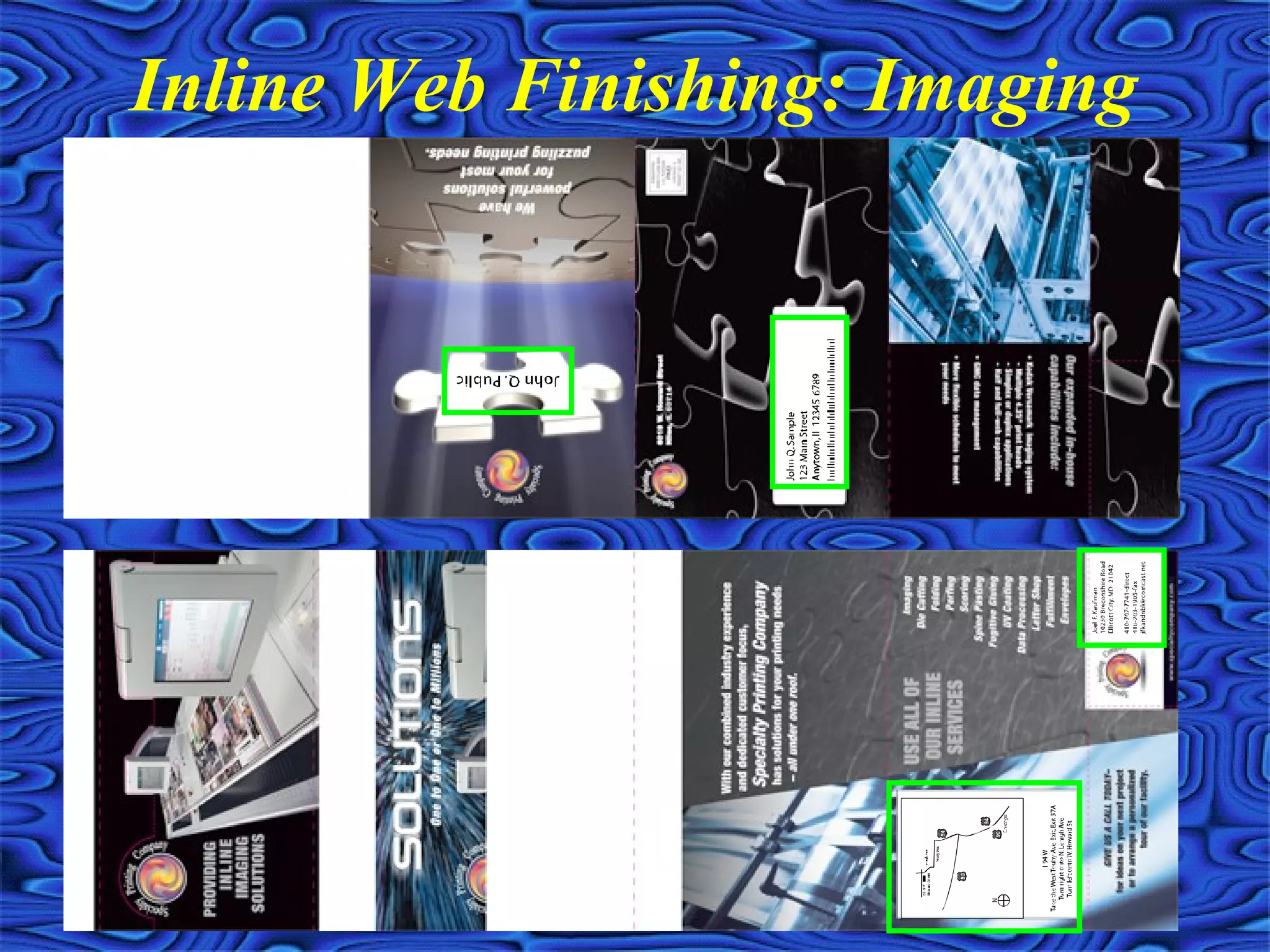

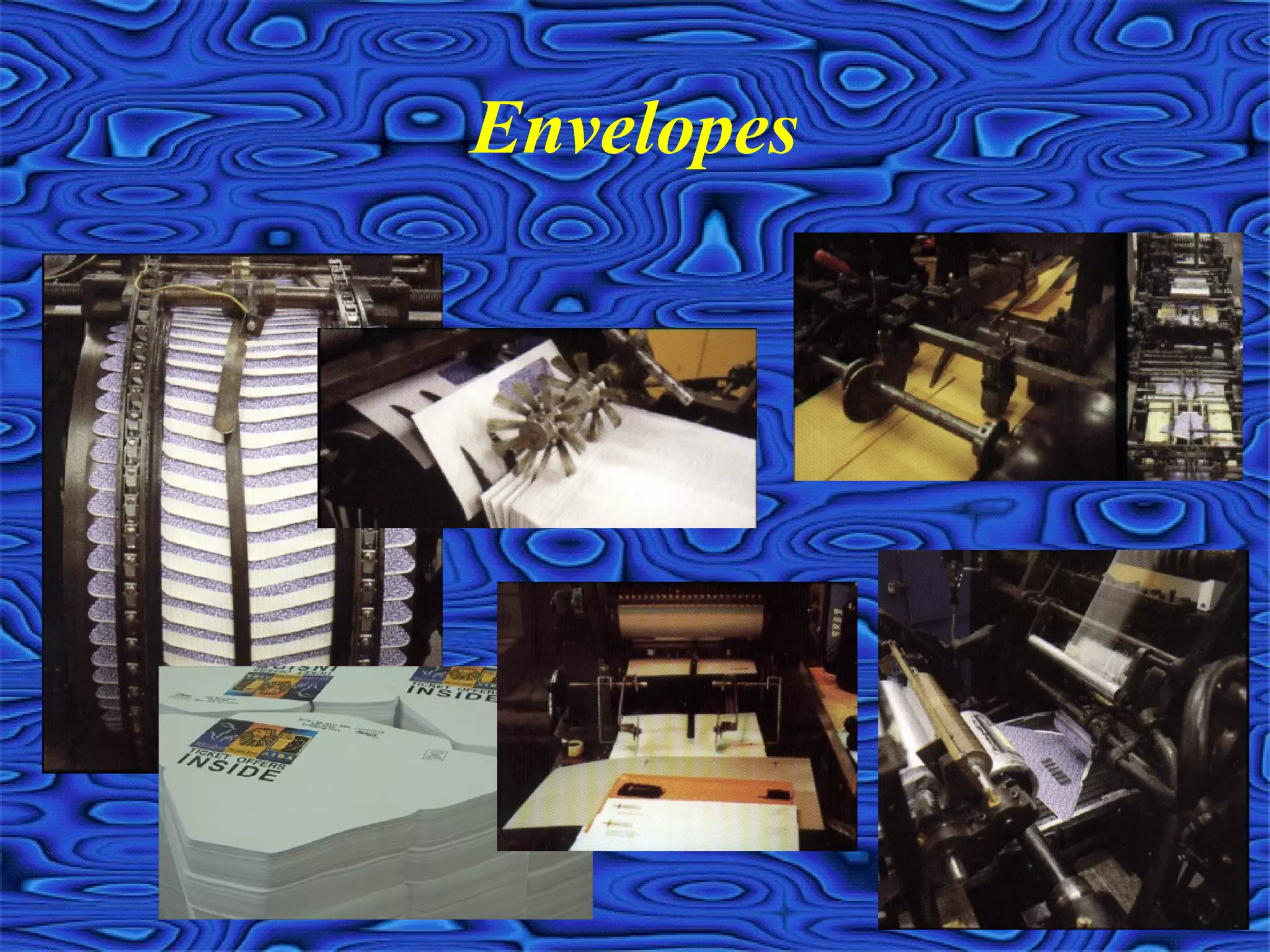

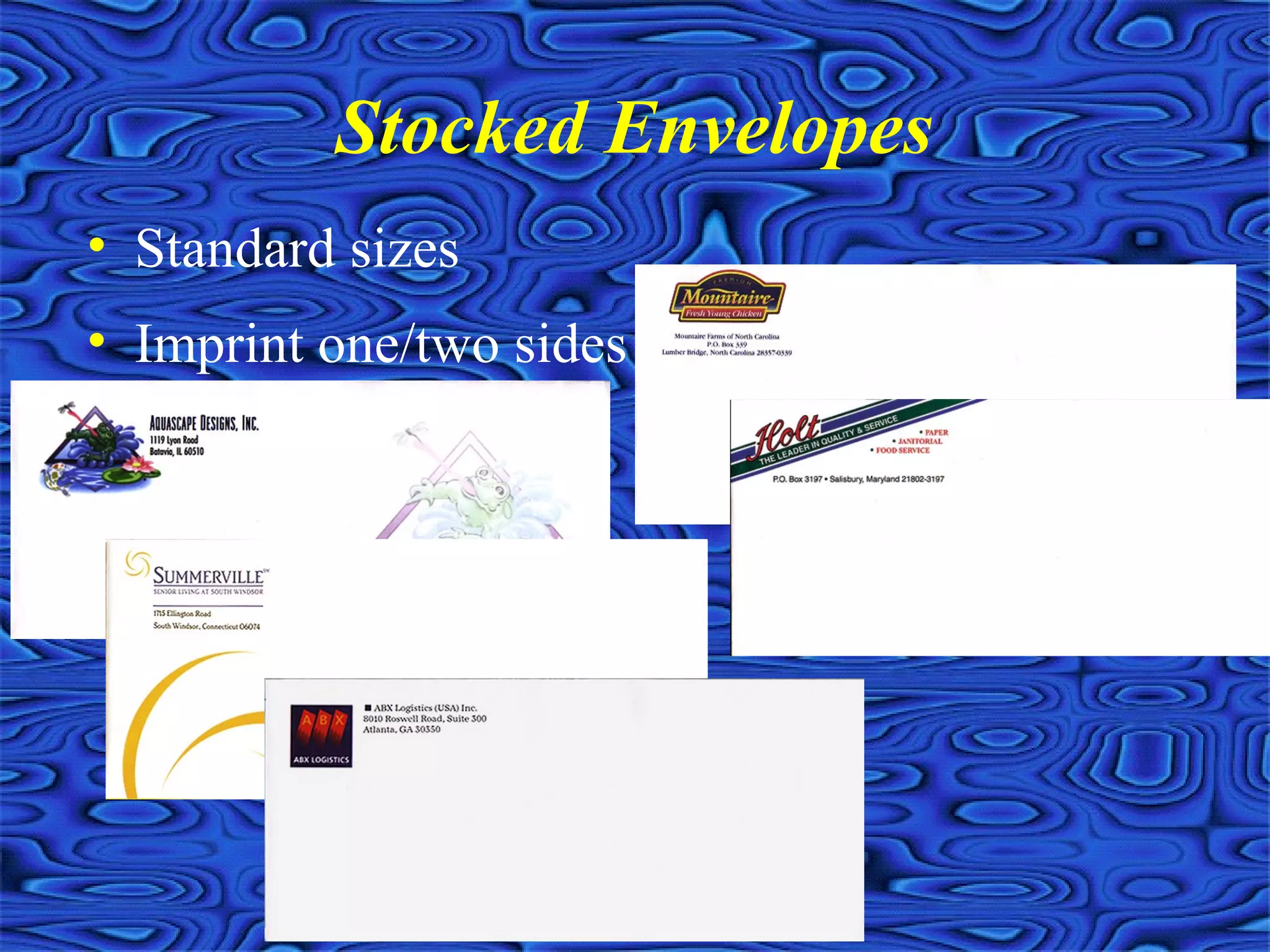

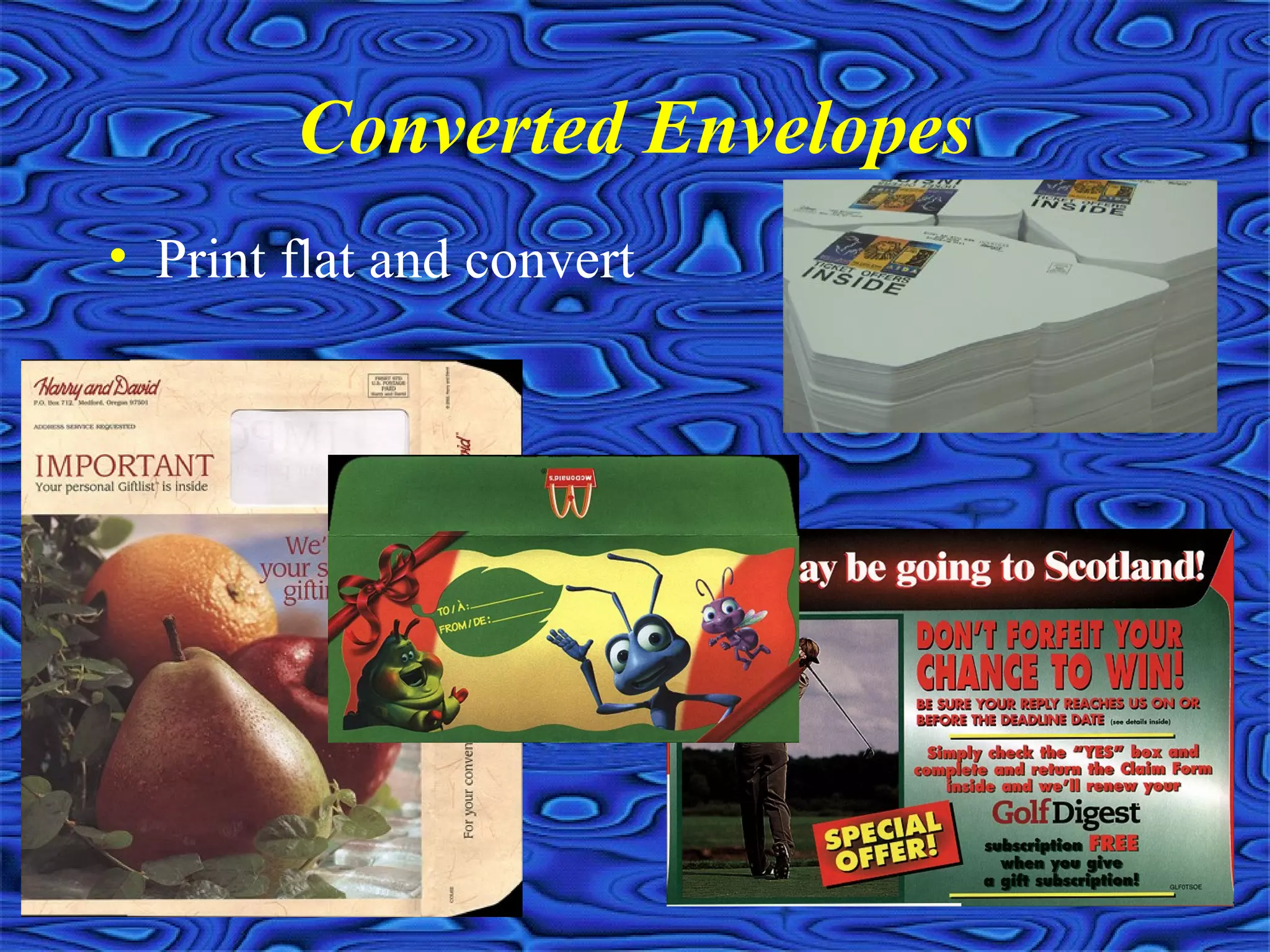

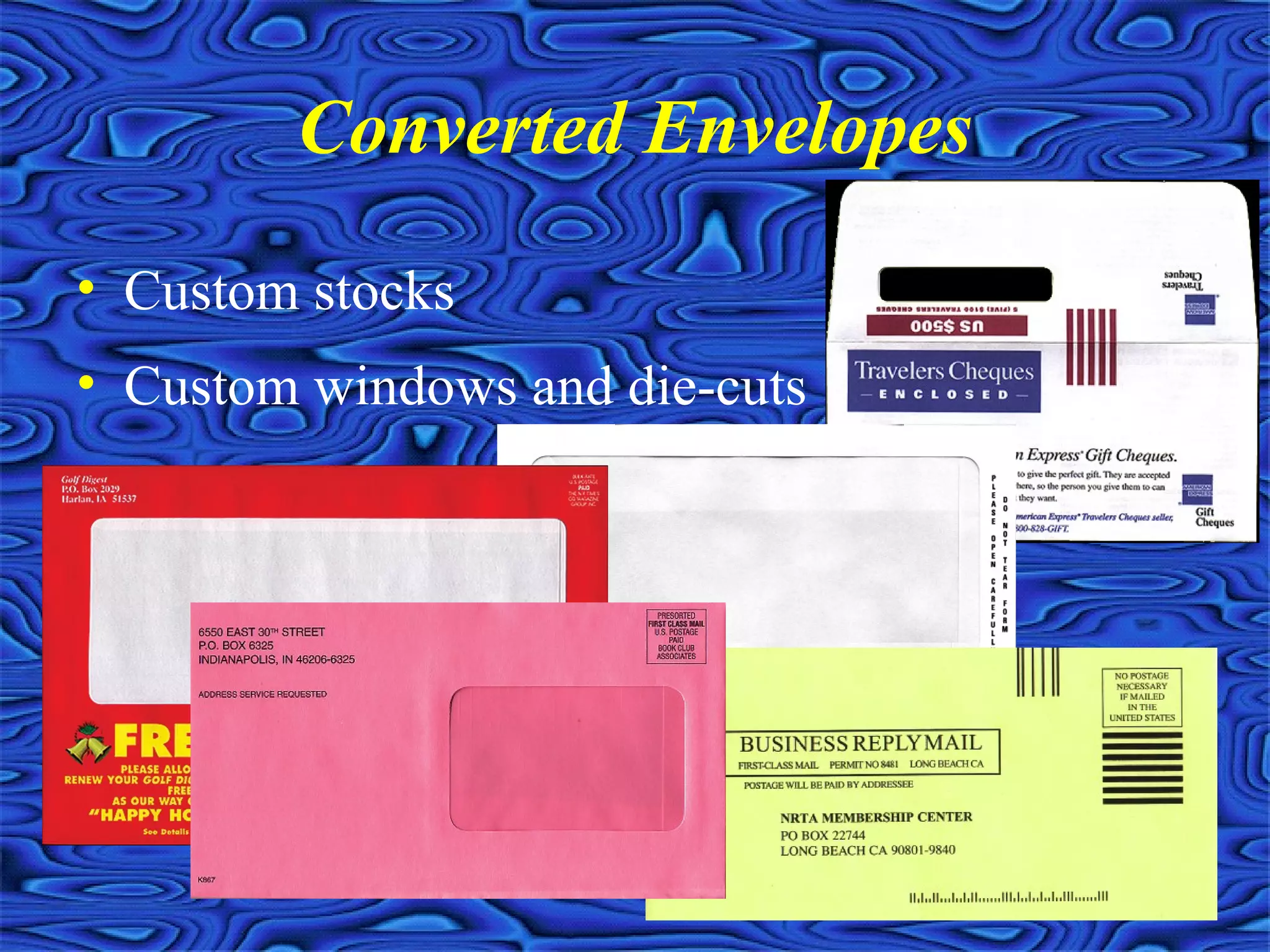

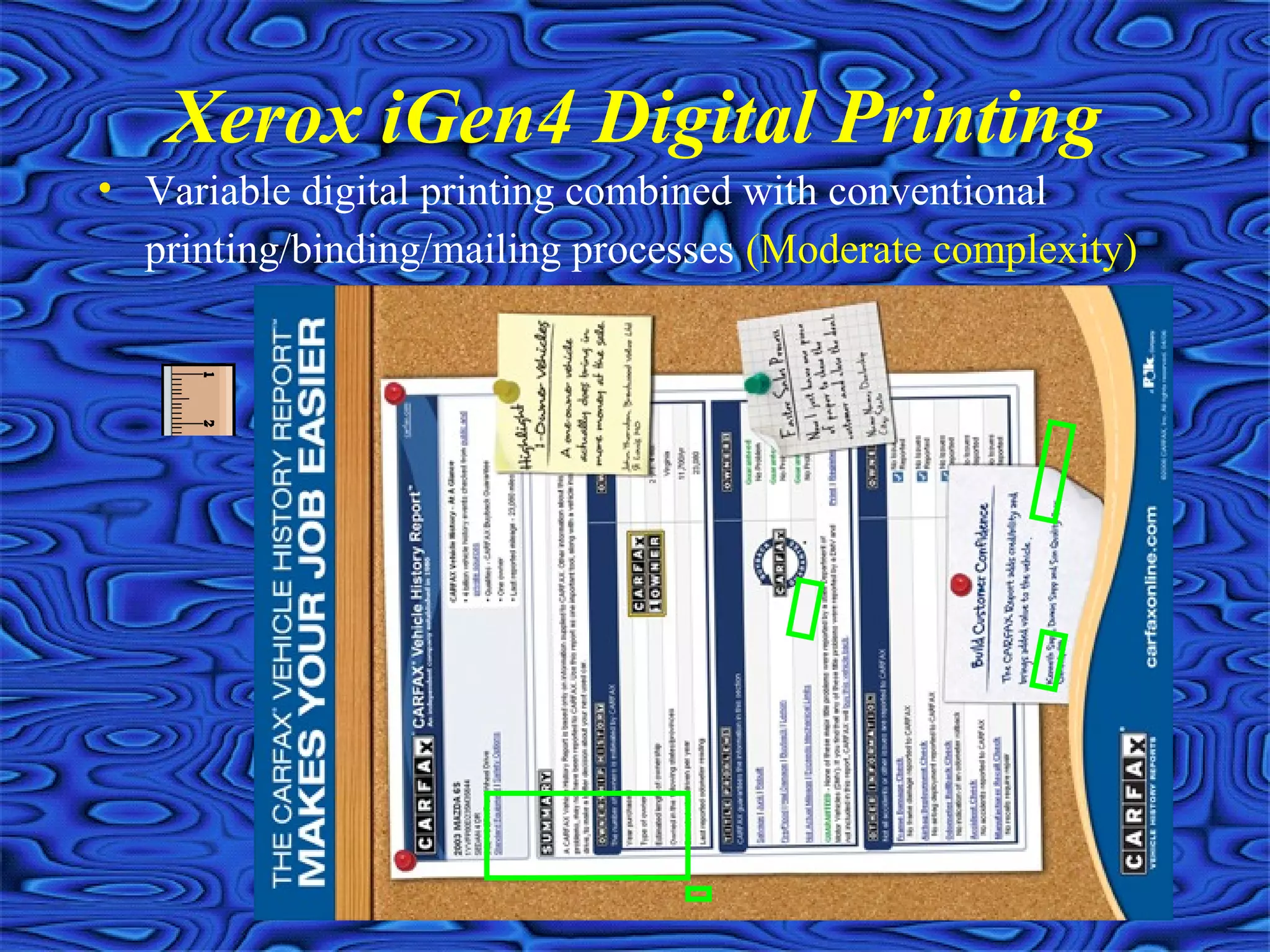

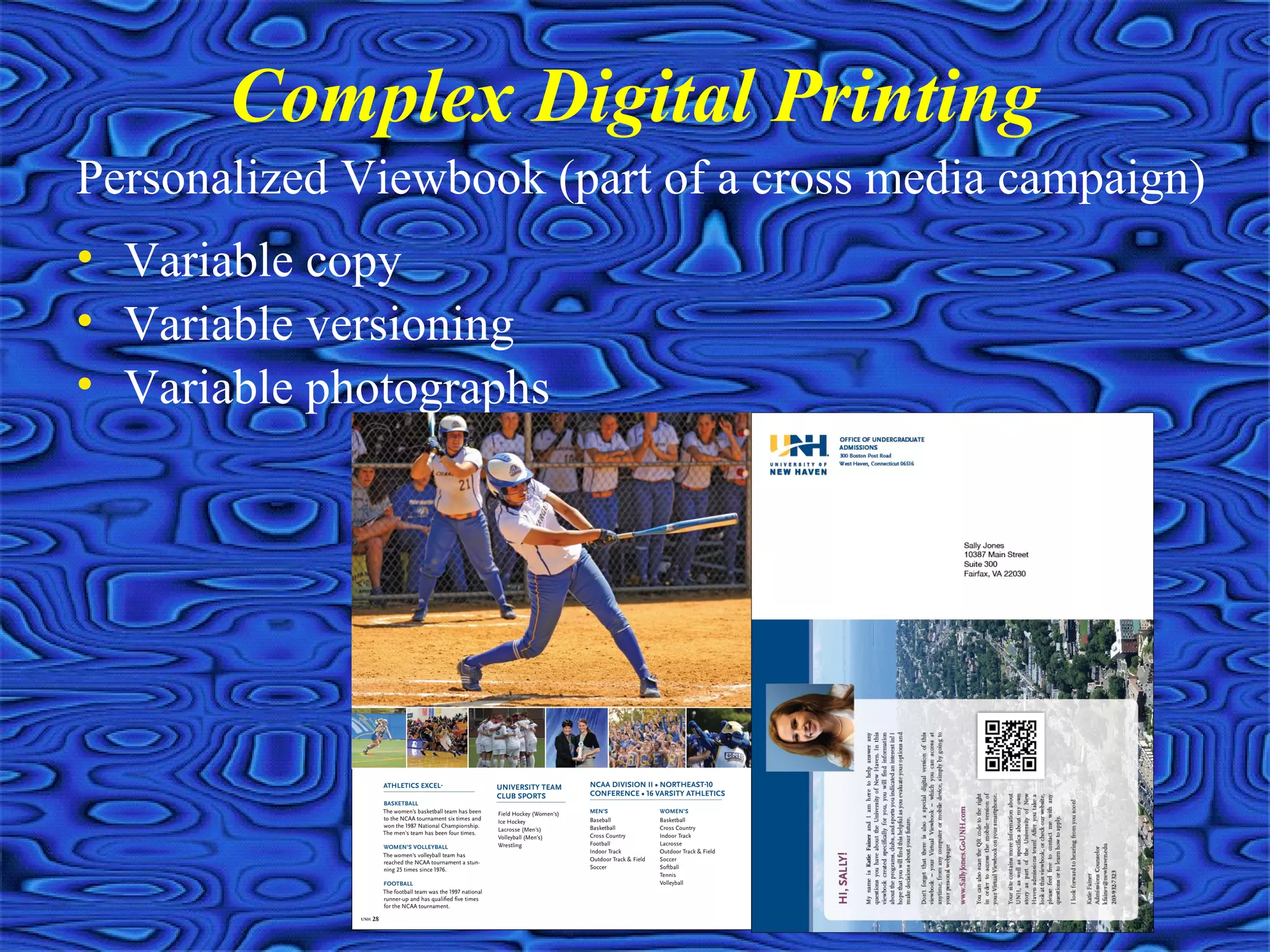

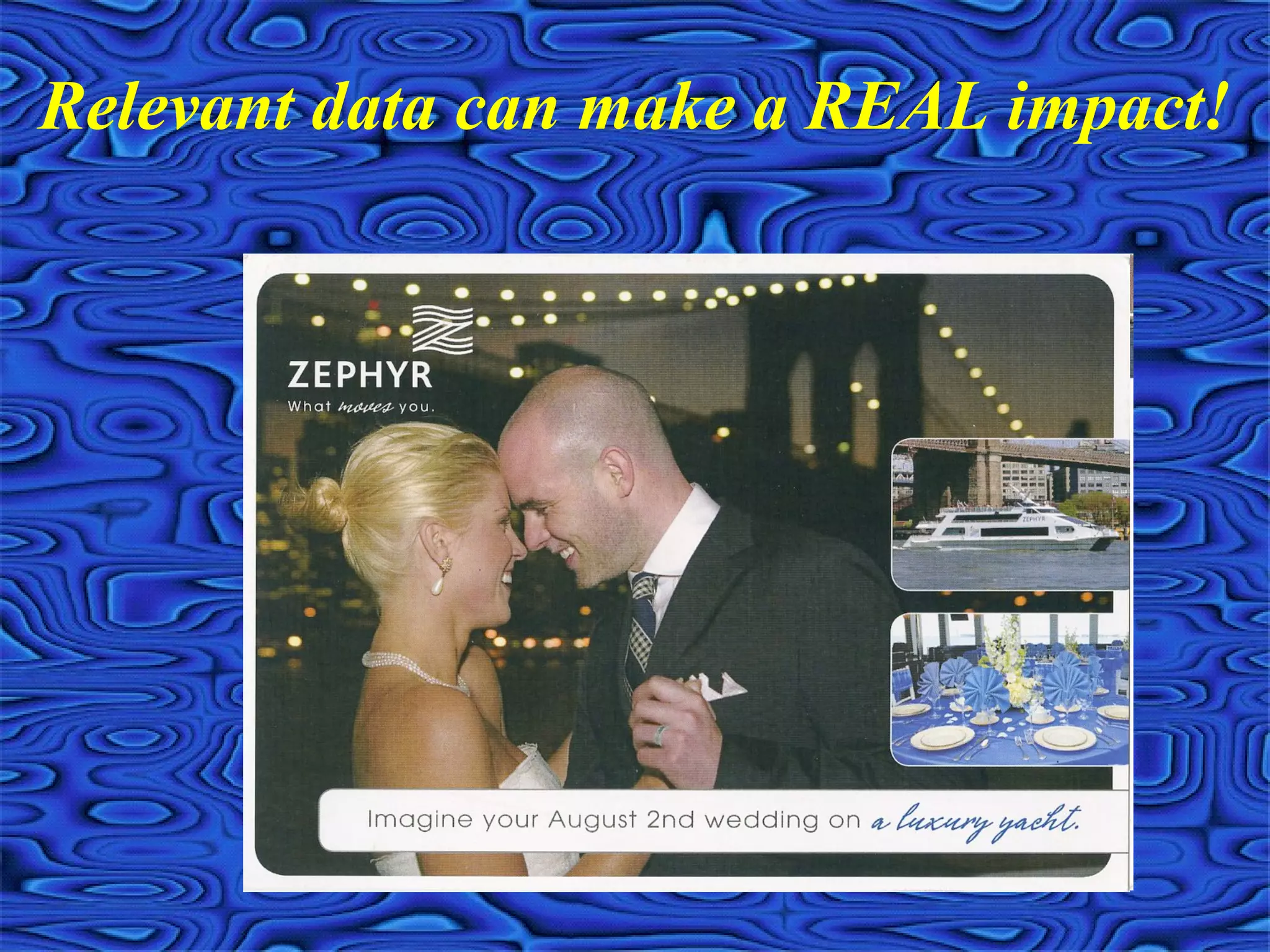

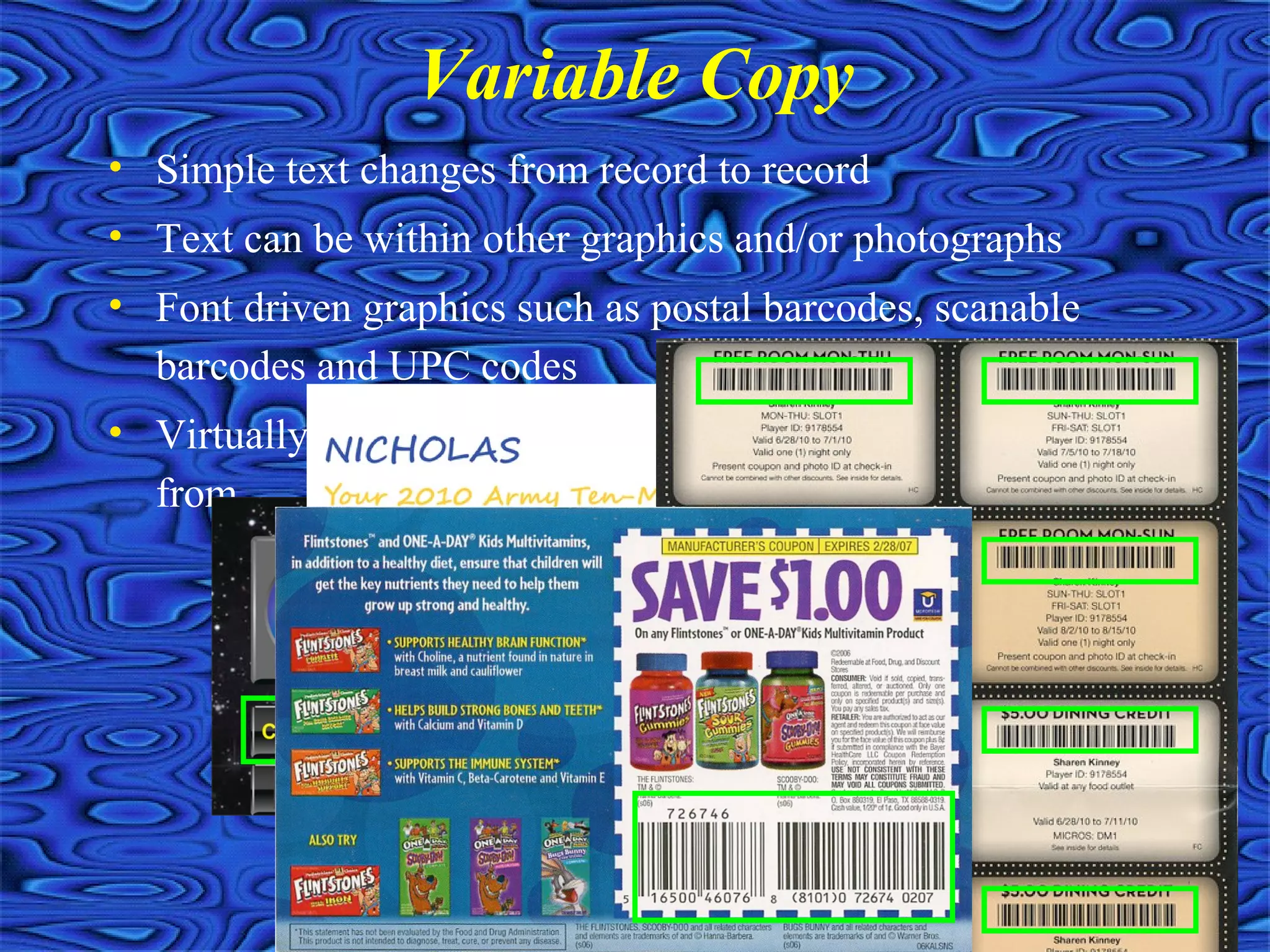

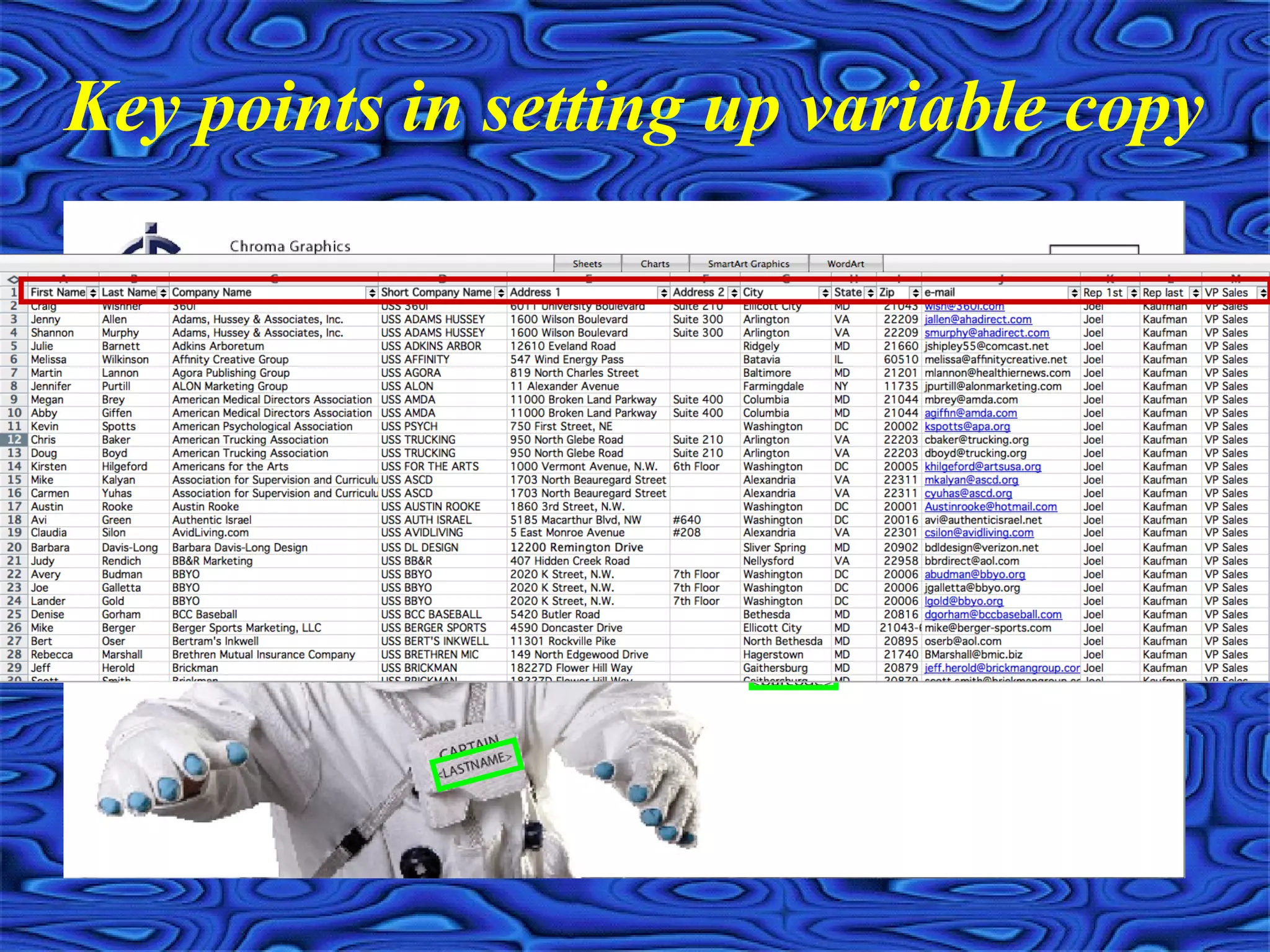

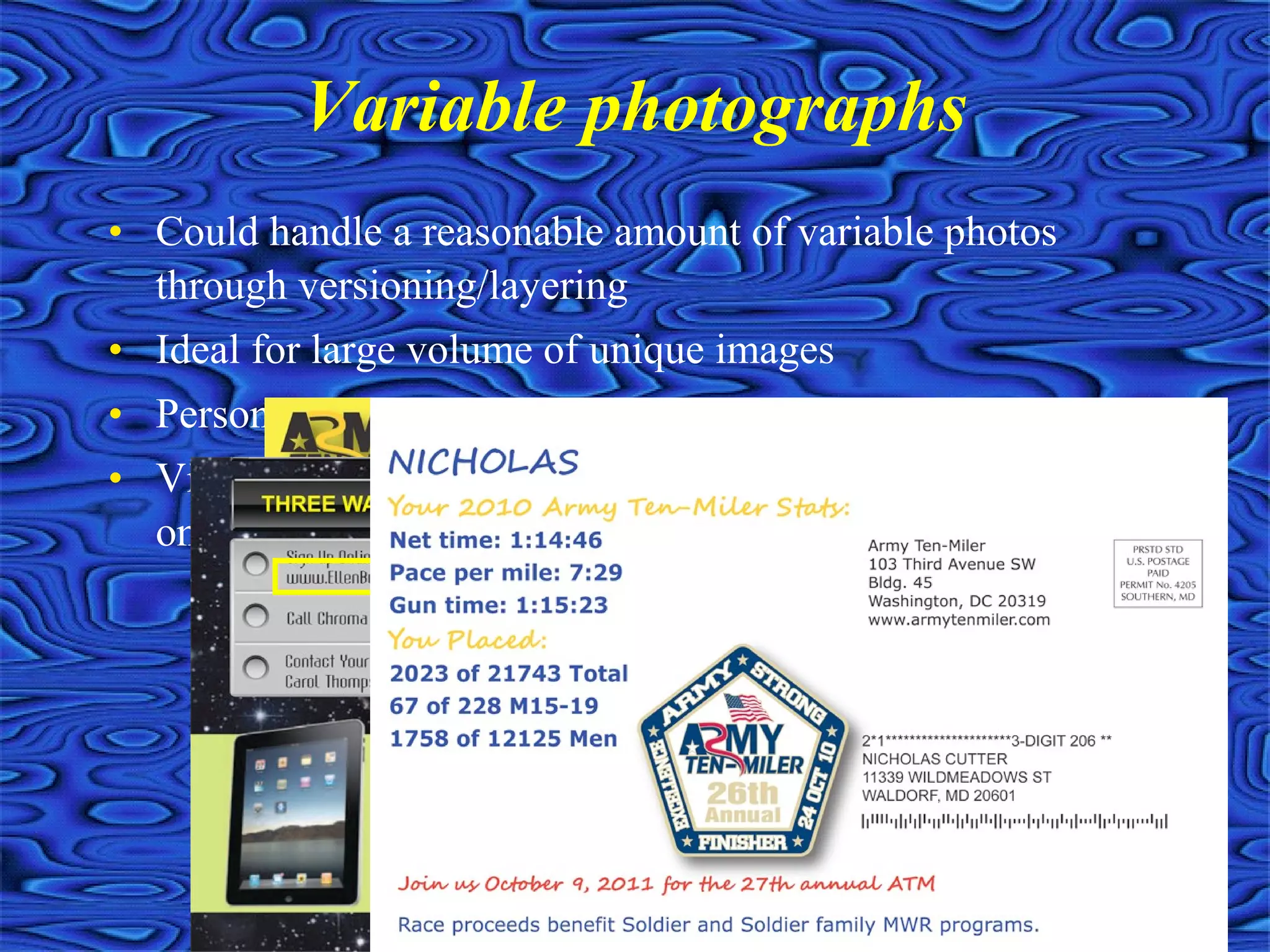

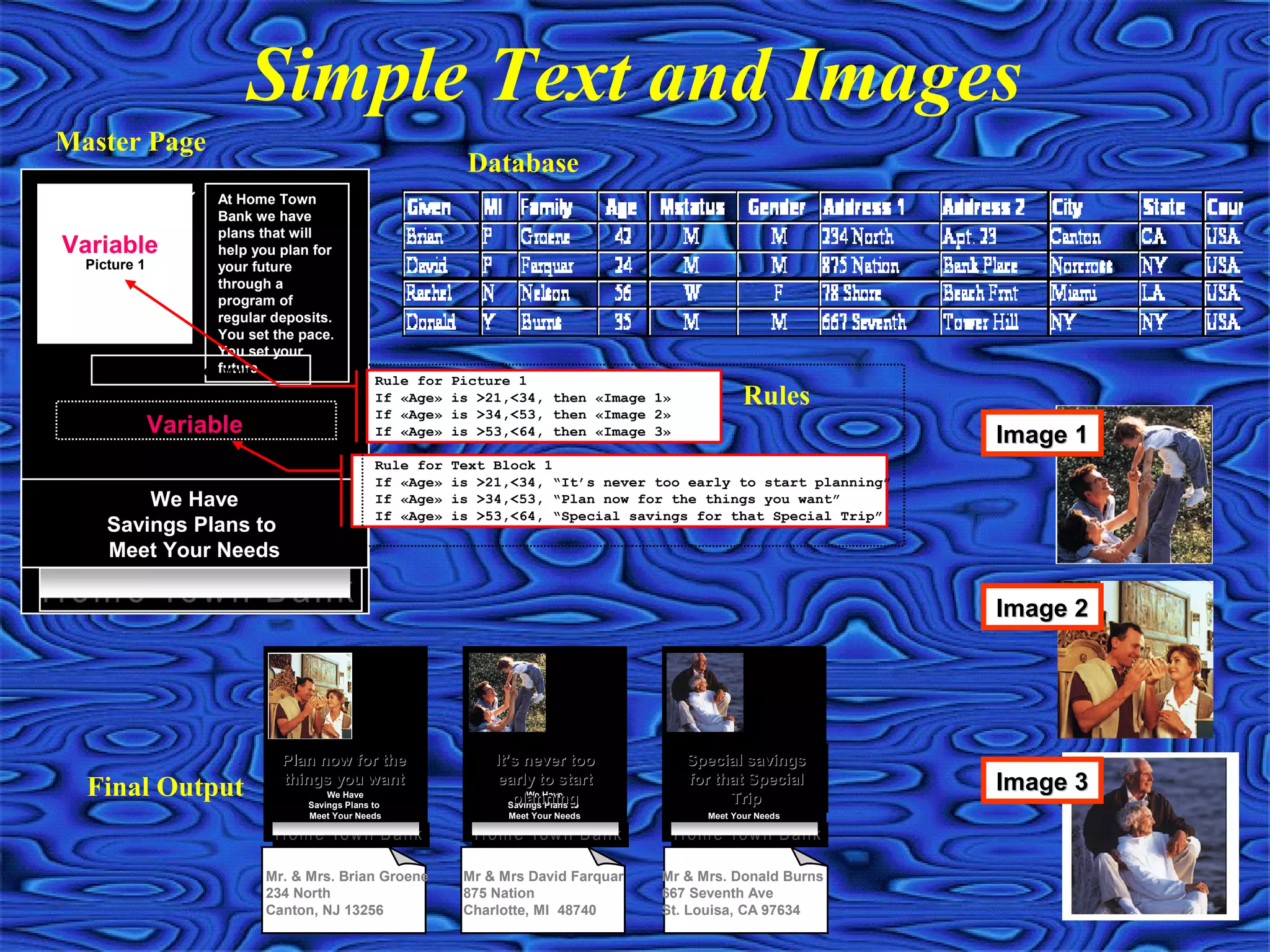

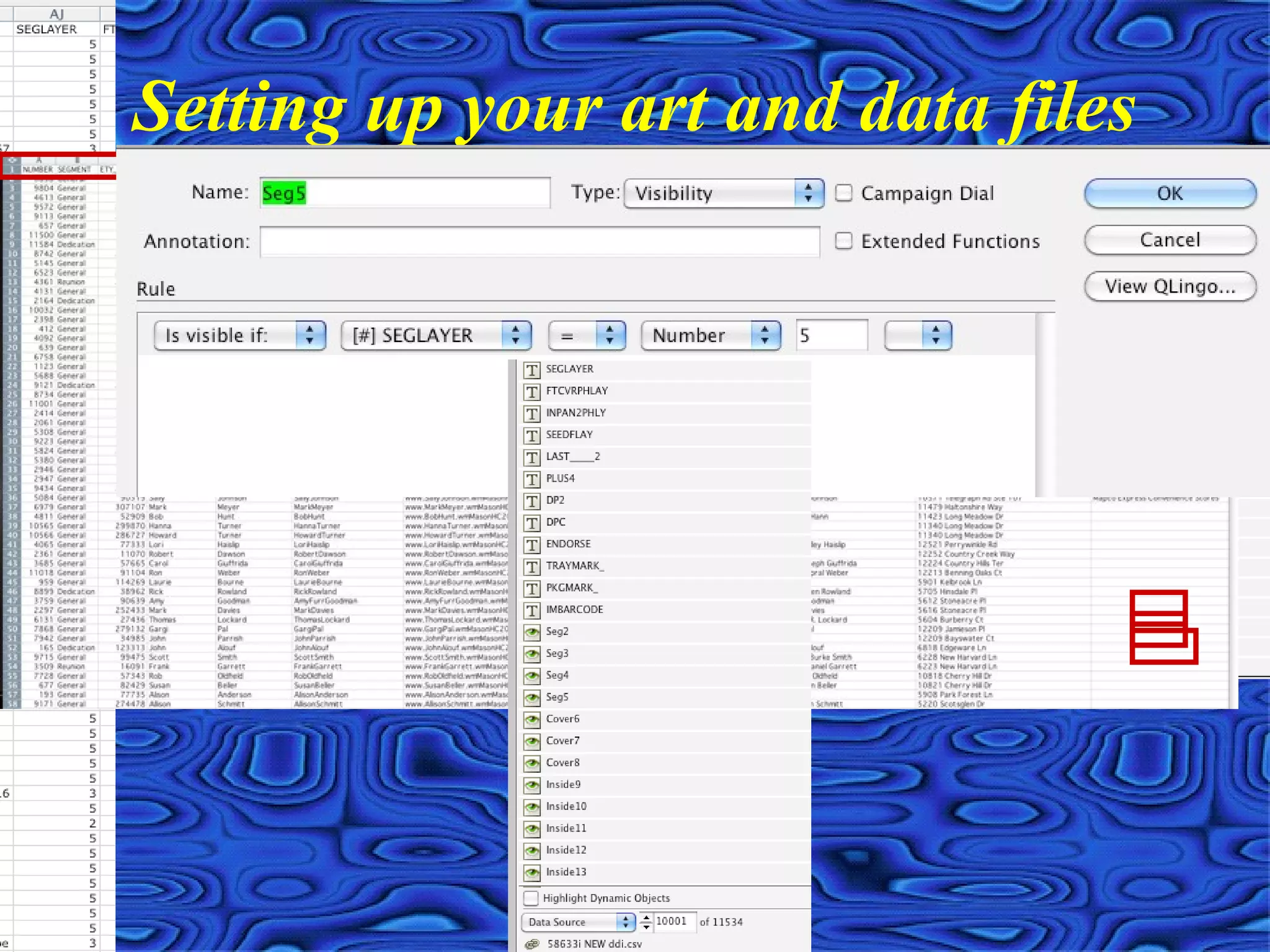

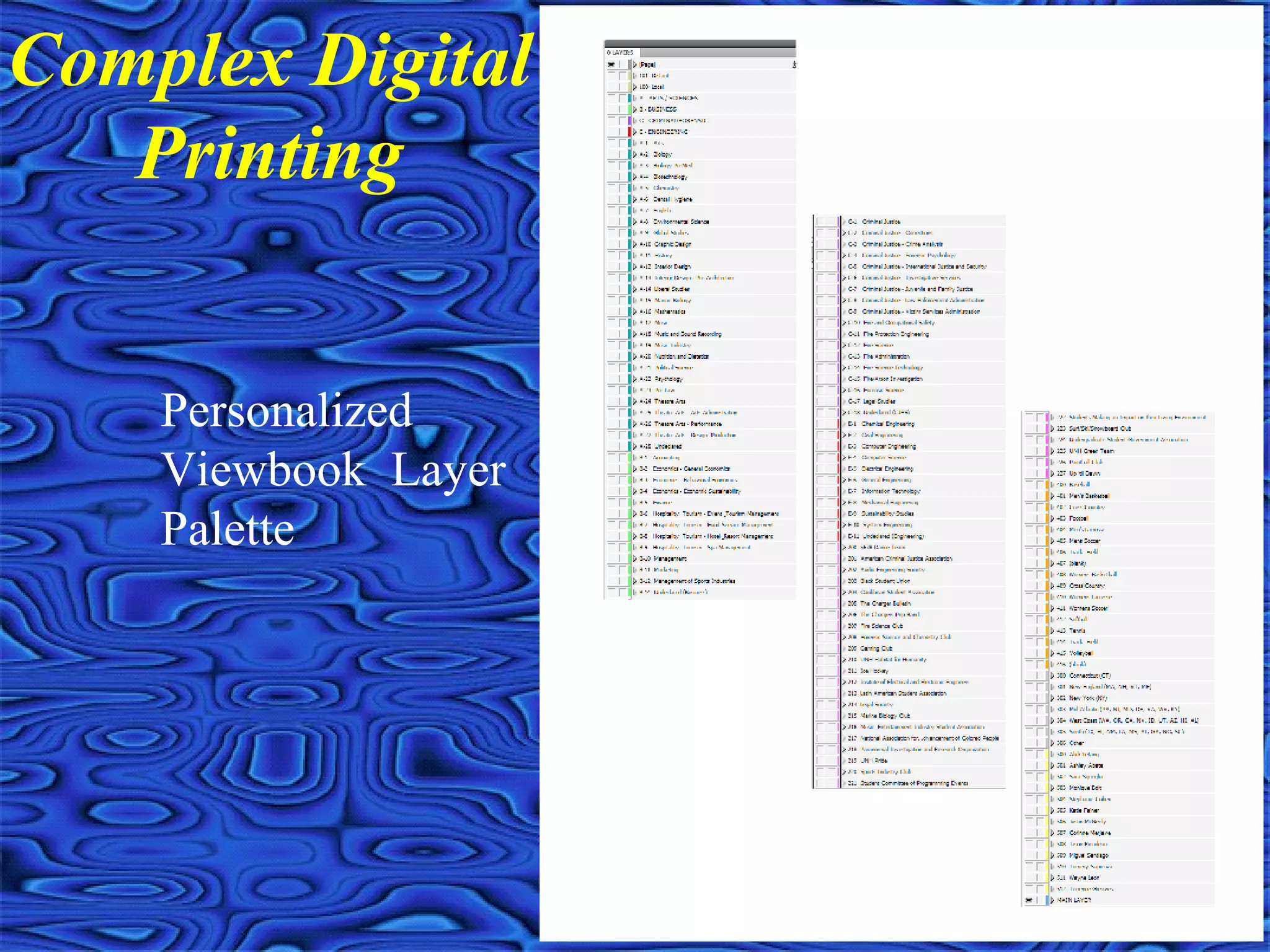

This document provides an overview of different types of conventional printing and digital printing, as well as tips for printing projects. It discusses sheetfed printing, web printing, and envelopes. For web printing, it describes various inline finishing capabilities like plow folding, die cutting, and 4-color process imaging. The document also provides tips for providing specifications, avoiding problems, cutting costs without sacrificing quality, and involving printing suppliers. Finally, it discusses digital and variable content printing, including hybrid conventional/digital workflows and complex variable data projects.