Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

PRESENTATION-Commissioning Experiences on Ammonia and Urea projects- Independ...

PRESENTATION-Commissioning Experiences on Ammonia and Urea projects- Independ...

F E R T I L I Z E R I N D U S T R Y L E C T U R E 1

F E R T I L I Z E R I N D U S T R Y L E C T U R E 1

Urea Dust & Ammonia Emission Control Prill Tower Project at Al Bayroni

Urea Dust & Ammonia Emission Control Prill Tower Project at Al Bayroni

Thyssenkrupp uhde advanced ammonia processes dual pressure

Thyssenkrupp uhde advanced ammonia processes dual pressure

Recent advancements in ammonia and urea industries

Recent advancements in ammonia and urea industries

Similar to Ammonia process

Similar to Ammonia process (20)

Urea plant energy improved by installing vortex mixture

Urea plant energy improved by installing vortex mixture

Ureaplantenergysavingbyselectionoflinermaterialandinernals

Ureaplantenergysavingbyselectionoflinermaterialandinernals

A Modular C2 Splitter - Hydrocarbon Engineering April 2017

A Modular C2 Splitter - Hydrocarbon Engineering April 2017

topsoe_ammonia_4_start_up_worlds_largest_ammonia_plant.pdf

topsoe_ammonia_4_start_up_worlds_largest_ammonia_plant.pdf

Study on Thermo-Electric Generator and hydrogen recirculation on Solid Oxide ...

Study on Thermo-Electric Generator and hydrogen recirculation on Solid Oxide ...

mitacs uoit study it05701 july 2015 vezina comparative ammonia costs producti...

mitacs uoit study it05701 july 2015 vezina comparative ammonia costs producti...

IRJET- Process Simulation of High Pressure Urea Production from Carbon Dioxid...

IRJET- Process Simulation of High Pressure Urea Production from Carbon Dioxid...

The Role of Material in Fertilizers IndustrieswithEnergy saving.pdf

The Role of Material in Fertilizers IndustrieswithEnergy saving.pdf

The role of material in fertilizers industries with energy saving

The role of material in fertilizers industries with energy saving

Recently uploaded

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...Call Girls in Nagpur High Profile

Recently uploaded (20)

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

Coefficient of Thermal Expansion and their Importance.pptx

Coefficient of Thermal Expansion and their Importance.pptx

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

Call for Papers - International Journal of Intelligent Systems and Applicatio...

Call for Papers - International Journal of Intelligent Systems and Applicatio...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Ammonia process

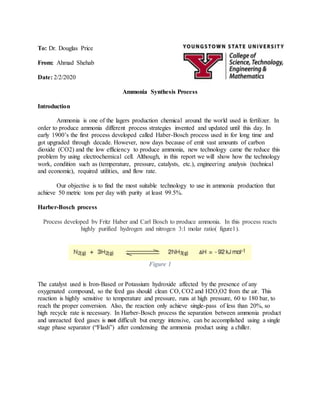

- 1. To: Dr. Douglas Price From: Ahmad Shehab Date: 2/2/2020 Ammonia Synthesis Process Introduction Ammonia is one of the lagers production chemical around the world used in fertilizer. In order to produce ammonia different process strategies invented and updated until this day. In early 1900’s the first process developed called Haber-Bosch process used in for long time and got upgraded through decade. However, now days because of emit vast amounts of carbon dioxide (CO2) and the low efficiency to produce ammonia, new technology came the reduce this problem by using electrochemical cell. Although, in this report we will show how the technology work, condition such as (temperature, pressure, catalysts, etc.), engineering analysis (technical and economic), required utilities, and flow rate. Our objective is to find the most suitable technology to use in ammonia production that achieve 50 metric tons per day with purity at least 99.5%. Harber-Bosch process Process developed by Fritz Haber and Carl Bosch to produce ammonia. In this process reacts highly purified hydrogen and nitrogen 3:1 molar ratio( figure1). Figure 1 The catalyst used is Iron-Based or Potassium hydroxide affected by the presence of any oxygenated compound, so the feed gas should clean CO, CO2 and H2O,O2 from the air. This reaction is highly sensitive to temperature and pressure, runs at high pressure, 60 to 180 bar, to reach the proper conversion. Also, the reaction only achieve single-pass of less than 20%, so high recycle rate is necessary. In Harber-Bosch process the separation between ammonia product and unreacted feed gases is not difficult but energy intensive, can be accomplished using a single stage phase separator (“Flash”) after condensing the ammonia product using a chiller.

- 2. Figure 2 Figure 2 shows the process where nitrogen and hydrogen goes into iron catalyst at 200 atm pressure and temperature of 400-450 Celsius. Then to a separation column separate ammonia products as a liquid after cooling down the temperature and hydrogen and nitrogen in gas phase goes to the recycle stream. Even though each pass of hydrogen and nitrogen conversion making less that 20%, the over conversion is 98%. However, one of the problems in this process is no reaction occur on the surface of the catalyst, so we need to shift the equilibrium position to the right as far as possible in order to produce maximum amount of ammonia. In addition, we need to lower the temperature as possible to increase the efficiency but because of the high temperature in the process 400-450 Celsius, the goal is to reach equilibrium within very short time that will in contact with the catalyst. Separating the ammonia The temperature of the liquid is lowered enough to turn the ammonia to a liquid the nitrogen and hydrogen remain gases and can be recycled. Economics - High pressure needs extremely strong pipes and vessels to withstand that increase Capital Cost when plant is build. - Running cost is high because of the pressure. - Adding catalyst only speed up the reaction, no effect on position of the equilibrium (almost no reaction without catalyst). - 10 MW per metric ton best of 7.8 MW. Electrochemical Cell

- 3. Figure 3 Electrochemical cell one of the modern synthesis to produce ammonia. Simply we have the electrolyze and the water inter the anode side where hydrogen is separated from oxygen. Then hydrogen moves to the cathode through membrane where nitrogen flow from the other side to contact with the hydrogen on the cathode to make ammonia by using renewable energy to power the system. Oxygen goes out as undesired product. Figure 4 shows the reaction. Figure 4 This technology moderate temperature at 150–350 °C and low <100 °C. also, low pressure. Advantages 1- Low temperature, low pressure. 2- 50% less CO2 emissions. 3- High efficiency. 4- Purity of 99.999% 5- 7 MW per metric ton. Disadvantages 1- Slow process. 2- low catalytic activity of the cathodic electrode (and consequently, reduced Faradaic Efficiency) 3- low protonic conductivity of the cell. Since this technology is new we need to consider these:

- 4. A- selection of materials and construction of the cathodic electrode. B- design and fabrication of the electrolyte-electrode interphase. C- selection of the operating conditions Conclusion Electrochemical Cell is great option to produce ammonia however this technology need for intensive collaboration among scientists and engineers working in different fields (solid state Ionics, catalysis, electrochemistry, reactor design) in order to bring this process into industrial practice. On the other hand, Haber-Bosch process is better process for our plant design. In addition, there are a lot of alternatives to improve the process and we can apply the process in industry. Works Cited Clark, J. (2013, April). Haber Process. Retrieved from THE HABER PROCESS: https://www.chemguide.co.uk/physical/equilibria/haber.html Department of Chemical Engineering, A. U. (2019, Aug 30). Electrochemical Synthesis of Ammonia: Recent Efforts and Future Outlook. Retrieved from NCBI: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6780605/ RICHARDSON, J. (2016, Sep). Introduction to Ammonia Production. Retrieved from AICHE: https://www.aiche.org/resources/publications/cep/2016/september/introduction-ammonia- production Service, R. F. (2018, Jul 12). Ammonia—a renewable fuel made from sun, air, and water—could power the globe without carbon. Retrieved from Science: https://www.sciencemag.org/news/2018/07/ammonia-renewable-fuel-made-sun-air-and- water-could-power-globe-without-carbon