Simple Commission Calculation Heat Exchanger Rupture

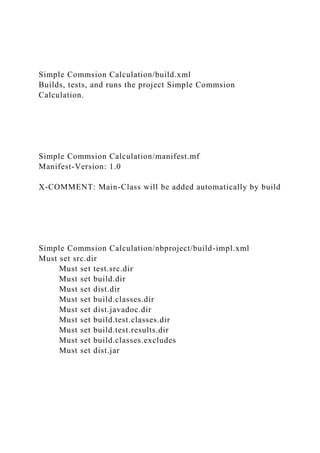

- 1. Simple Commsion Calculation/build.xml Builds, tests, and runs the project Simple Commsion Calculation. Simple Commsion Calculation/manifest.mf Manifest-Version: 1.0 X-COMMENT: Main-Class will be added automatically by build Simple Commsion Calculation/nbproject/build-impl.xml Must set src.dir Must set test.src.dir Must set build.dir Must set dist.dir Must set build.classes.dir Must set dist.javadoc.dir Must set build.test.classes.dir Must set build.test.results.dir Must set build.classes.excludes Must set dist.jar

- 15. Must set JVM to use for profiling in profiler.info.jvm Must set profiler agent JVM arguments in profiler.info.jvmargs.agent

- 18. Simple Commsion Calculation/nbproject/genfiles.properties build.xml.data.CRC32=fc93565a build.xml.script.CRC32=bc3fd3f6 [email protected] # This file is used by a NetBeans-based IDE to track changes in generated files such as build-impl.xml. # Do not edit this file. You may delete it but then the IDE will never regenerate such files for you. nbproject/build-impl.xml.data.CRC32=fc93565a nbproject/build-impl.xml.script.CRC32=fa3fac4c nbproject/[email protected] Simple Commsion Calculation/nbproject/project.properties annotation.processing.enabled=true annotation.processing.enabled.in.editor=false annotation.processing.processor.options= annotation.processing.processors.list= annotation.processing.run.all.processors=true

- 19. annotation.processing.source.output=${build.generated.sources. dir}/ap-source-output build.classes.dir=${build.dir}/classes build.classes.excludes=**/*.java,**/*.form # This directory is removed when the project is cleaned: build.dir=build build.generated.dir=${build.dir}/generated build.generated.sources.dir=${build.dir}/generated-sources # Only compile against the classpath explicitly listed here: build.sysclasspath=ignore build.test.classes.dir=${build.dir}/test/classes build.test.results.dir=${build.dir}/test/results # Uncomment to specify the preferred debugger connection transport: #debug.transport=dt_socket debug.classpath= ${run.classpath} debug.test.classpath= ${run.test.classpath}

- 20. # Files in build.classes.dir which should be excluded from distribution jar dist.archive.excludes= # This directory is removed when the project is cleaned: dist.dir=dist dist.jar=${dist.dir}/Simple_Commsion_Calculation.jar dist.javadoc.dir=${dist.dir}/javadoc excludes= includes=** jar.compress=false javac.classpath= # Space-separated list of extra javac options javac.compilerargs= javac.deprecation=false javac.processorpath= ${javac.classpath} javac.source=1.8 javac.target=1.8 javac.test.classpath=

- 22. meta.inf.dir=${src.dir}/META-INF mkdist.disabled=false platform.active=default_platform run.classpath= ${javac.classpath}: ${build.classes.dir} # Space-separated list of JVM arguments used when running the project. # You may also define separate properties like run-sys- prop.name=value instead of -Dname=value. # To set system properties for unit tests define test-sys- prop.name=value: run.jvmargs= run.test.classpath= ${javac.test.classpath}: ${build.test.classes.dir} source.encoding=UTF-8 src.dir=src test.src.dir=test

- 23. Simple Commsion Calculation/nbproject/project.xml org.netbeans.modules.java.j2seproject Simple Commsion Calculation Simple Commsion Calculation/src/simple/commsion/calculation/SalesPerson.javaS imple Commsion Calculation/src/simple/commsion/calculation/SalesPerson.java/* * Title: Simple Commision Calculation * Programmer: Melody Frost * PRG 420 Java Programming I * Instructor: Henry Williams * University of Phoenix * This program will calculate the total annual compesation of a sales person. * Sales commision of 15% and prompt user to end annual sales plus displays * total annual compensation */ package simple.commsion.calculation; /** *

- 24. * @author Melody Frost */ classSalesPerson{ /** * Instance variables for storing data */ privatedouble fixedCompensation; privatedouble variablePercent; /** * Default constructor */ publicSalesPerson(){ } /** * * @param fixedCompensation * @param variablePercent */ publicSalesPerson(double fixedCompensation,double variablePe rcent){ this.fixedCompensation = fixedCompensation; this.variablePercent = variablePercent; } /** * accessors method for fixedCompensation * * @return fixedCompensation */ publicdouble getFixedCompensation(){ return fixedCompensation; }

- 25. /** * Mutator for fixedCompensation * * @param fixedCompensation */ publicvoid setFixedCompensation(double fixedCompensation){ this.fixedCompensation = fixedCompensation; } /** * accessors for variablePercent * * @return variablePercent */ publicdouble getVariablePercent(){ return variablePercent; } /** * Mutator for variablePercent * * @param variablePercent */ publicvoid setVariablePercent(double variablePercent){ this.variablePercent = variablePercent; } /** * This method calculates and returns the total compensation. * * @param sales * @return totalCompensation */ publicdouble calculateTotalCompensation(double sales){ // Assume sales target is 150,000 double salesTarget =150000;

- 26. // Sales incentive will kick in only if 80% of sales target has be en reached // and up to sales target double salesNeededForIncentive =0.80* salesTarget; double commissionRate; // All sales that exceed the sales target will earch an acceleratio n of 2.0. double accelerationFactor =2.0; if(sales > salesNeededForIncentive && sales <= salesTarget){ commissionRate = getVariablePercent(); }elseif(sales > salesTarget){ // Above the target, the commission increases to incentiveRate x // acceleration factor commissionRate = accelerationFactor; }else{ // Target not met commissionRate =0; } return getFixedCompensation()+(sales * commissionRate); } } Simple Commsion Calculation/src/simple/commsion/calculation/SimpleCommsion Calculation.javaSimple Commsion Calculation/src/simple/commsion/calculation/SimpleCommsion Calculation.java/* * Title: Simple Commision Calculation Week 3 * Programmer: Melody Frost * PRG 420 Java Programming I * Instructor: Henry Williams * University of Phoenix

- 27. * This program will calculate the total annual compesation of a salesperson. * * Sales commision of 15% and prompt user ot end annual sale s plus displays * total annual compensation */ package simple.commsion.calculation; import java.text.NumberFormat; import java.util.Locale; import java.util.Scanner; /** * * @author Melody Frost */ publicclassSimpleCommsionCalculation{ /** * Program execution starts here * * @param args the command line arguments */ publicstaticvoid main(String[] args){ // Command to format currency NumberFormat numberFormat =NumberFormat.getCurrencyInst ance(Locale.US); // Command for accepting input Scanner input =newScanner(System.in); // Command to prompt the user and accept sales amount System.out.print("Enter sales: "); double sales = input.nextDouble(); // Fixed annual salary of 85000 and commission rate of 15%

- 28. double fixedSalary =850000; double commissionRate =0.15; // Command to initialize sales person object with default values SalesPerson salesPerson =newSalesPerson(fixedSalary, commiss ionRate); // Command to calculate the total compensation and display it in // currency format System.out.println("Total compensation: "+ numberFormat.form at(salesPerson.calculateTotalCompensation(sales))); // Create table for possible total compensation double maxSales =2.0* sales; double salesAmount = sales; System.out.println("Total SalesttTotal compensation"); while(salesAmount <= maxSales){ System.out.println(numberFormat.format(salesAmount)+"tt" + numberFormat.format(salesPerson.calculateTotalCompensatio n(salesAmount))); salesAmount = salesAmount +5000; } } } CASE STUDY Heat exchanger rupture and ammonia release in Houston, Texas (One Killed, Six Injured) 2008-06-I-TX January 2011

- 29. The Goodyear Tire and Rubber Company Houston, TX June 11, 2008 Key Issues: • Emergency Response and Accountability • Maintenance Completion • Pressure Vessel Over-pressure Protection Introduction This case study examines a heat exchanger rupture and ammonia release at The Goodyear Tire and Rubber Company plant in Houston, Texas. The rupture and release injured six employees. Hours after plant responders declared the emergency over; the body of an employee was discovered in the debris next to the heat exchanger. INSIDE . . .

- 30. Incident Description Background Analysis Lessons Learned Goodyear Houston Case Study January 2011 2 1.0 Incident Description This case study examines a heat exchanger rupture and ammonia release at The Goodyear Tire and Rubber Company (Goodyear) facility in Houston, Texas, that killed one worker and injured six others. Goodyear uses pressurized anhydrous ammonia in the heat exchanger to cool the chemicals used to make synthetic rubber. Process chemicals pumped through tubes inside the heat exchanger are cooled by ammonia flowing around the tubes in a cylindrical steel shell. On June 10, 2008, Goodyear operators closed an isolation valve between the heat exchanger shell (ammonia cooling side) and a relief valve to replace a burst rupture disk

- 31. under the relief valve that provided over- pressure protection. Maintenance workers replaced the rupture disk on that day; however, the closed isolation valve was not reopened. On the morning of June 11, an operator closed a block valve isolating the ammonia pressure control valve from the heat exchanger. The operator then connected a steam line to the process line to clean the piping. The steam flowed through the heat exchanger tubes, heated the liquid ammonia in the exchanger shell, and increased the pressure in the shell. The closed isolation and block valves prevented the increasing ammonia pressure from safely venting through either the ammonia pressure control valve or the rupture disk and relief valve. The pressure in the heat exchanger shell continued climbing until it violently ruptured at about 7:30 a.m. The catastrophic rupture threw debris that struck and killed a Goodyear employee walking through the area. The rupture also released ammonia, exposing five nearby workers to the chemical. One additional worker was injured while exiting the area. Immediately after the rupture and resulting ammonia release, Goodyear evacuated the plant. Medical responders transported the six injured workers. The employee tracking

- 32. system failed to properly account for all workers and as a result, Goodyear management believed all workers had safely evacuated the affected area. Management declared the incident over the morning of June 11, although debris blocked access to the area immediately surrounding the heat exchanger. Plant responders managed the cleanup while other areas of the facility resumed operations. Several hours later, after plant operations had resumed, a supervisor assessing damage in the immediate incident area discovered the body of a Goodyear employee located under debris in a dimly lit area (Figure 1). Figure 1. Area of fatality Goodyear Houston Case Study January 2011 3 2.0 Background 2.1 Goodyear Goodyear is an international tire and rubber manufacturing company founded in 1898

- 33. and headquartered in Akron, Ohio. North American facilities produce tires and tire components. The Houston facility, originally constructed in 1942 and expanded in 1989, produces synthetic rubber in several process lines. 2.1.1 Process Description The facility includes separate production and finishing areas. In the production area, a series of reactor vessels process chemicals, including styrene and butadiene. Heat exchangers in the reactor process line use ammonia to control temperature. Piping carries product from the reactors to the product finishing area. 2.1.2 Ammonia Heat Exchangers Ammonia is a commonly used industrial coolant. Goodyear uses three ammonia heat exchangers in its production process lines. The ammonia cooling system supplies the heat exchangers with pressurized liquid ammonia. As the ammonia absorbs heat from the process chemical flowing through tubes in the center of the heat exchanger, the ammonia boils in the heat exchanger shell (Figure 2). A pressure control valve in the vapor return line maintains ammonia pressure at 150 psig in the heat exchanger. Ammonia vapor returns to the ammonia cooling system where it is pressurized and cooled, liquefying the ammonia.

- 34. Figure 2. Ammonia heat exchanger Goodyear Houston Case Study January 2011 4 The process chemicals exiting the heat exchanger flow to the process reactors. Each heat exchanger is equipped with a rupture disk in series with a pressure relief valve (both set at 300 psig) to protect the heat exchanger from excessive pressure. The relief system vented ammonia vapor through the roof to the atmosphere. 2.2 Ammonia Properties Anhydrous ammonia is a colorless, toxic, and flammable vapor at room temperature. It has a pungent odor and is hazardous when inhaled, ingested, or if it contacts the skin or eyes. Ammonia vapor irritates the eyes and respiratory system and makes breathing difficult. Liquefied ammonia causes frostbite on contact. One cubic foot of liquid ammonia produces 850 cubic feet of vapor. Since ammonia vapor is lighter than air, it tends to rise. The vapor can also remain close to the ground when it absorbs water vapor from air

- 35. in high humidity conditions. The Occupational Safety and Health Administration (OSHA) and National Institute for Occupational Safety and Health (NIOSH) limit worker exposure to ammonia to 25 and 50 parts per million (ppm), respectively, over an 8-hour time-weighted average. Ammonia is detectable by its odor at 5 ppm. Goodyear Houston Case Study January 2011 5 3.0 Analysis 3.1 Emergency Procedures 3.1.1 Onsite Emergency Response Training Goodyear maintained a trained emergency response team, which attended off-site industrial firefighter training, conducted response drills based on localized emergency scenarios, and practiced implementing an emergency operations center. Other employees received emergency preparedness training primarily as part of their annual

- 36. computer-based health and safety training. Although Goodyear procedures required that a plant-wide evacuation and shelter- in-place drill be conducted at least four times a year, workers told the Chemical Safety Board (CSB) that such drills had not been conducted in the four years prior to the June 11th 2008 incident. Operating procedures discussed plant- wide, alarm operations and emergency muster points for partial and plant-wide evacuations; however, some employees had not been fully trained on these procedures. 3.1.2 Plant Alarm System Although Goodyear had installed a plant- wide alarm system, some workers reported that the system was unreliable, as in this case, when workers were not immediately made aware of the nature of the incident. Emergency alarm pull-boxes located throughout the production unit areas sound a location-specific alarm. However, ammonia vapor released from the ruptured heat exchanger and water spray from the automatic water deluge system prevented responders from reaching the alarm pull-box in the affected process unit. Supervisors and response team members were forced to notify some employees by radio and word-

- 37. of-mouth of the vessel rupture and ammonia release. 3.1.3 Accounting for Workers in an Emergency Facility operating procedures also outlined Goodyear’s worker emergency accountability scheme. Supervisors were to account for their employees using a master list generated from the computerized electronic badge-in/badge-out system. During the incident however, a malfunction in the badge tracking system delayed supervisors from immediately retrieving the list of personnel in their area. Handwritten employee and contractor lists were generated, listing the workers only as they congregated at the muster points or sheltered in place. Later, EOC personnel compared the handwritten lists against the computer record of personnel who remained badged in to the production areas. Additionally, although emergency response team members were familiar with the employee accountability procedures, not all supervisory and security employees, who were to conduct the accounting, had been trained on them. In fact, some of the employees responsible for accountability were unaware prior to the incident that their jobs could include this task in an emergency.

- 38. Since the fatally injured employee was a member of the emergency response team, area supervisors did not consider her absence from the muster point unusual. Goodyear Houston Case Study January 2011 6 The Emergency Operations Command (EOC) declared all Goodyear employees accounted for at about 8:40 a.m. Accounting for the contract employees continued until about 11:00 a.m., at which time the EOC ended the plant-wide evacuation and disbanded. Only the immediate area involved in the rupture remained evacuated. At about 1:20 p.m., an operations supervisor assessing the damage to the incident area discovered the victim buried in rubble in a dimly lit area and contacted City of Houston medical responders. 3.2 Maintenance Procedures Training requirements for operators in the production area included standard operating procedures specifically applicable to the rupture disk maintenance performed on June 10:

- 39. • Use of the work order system including obtaining signature verification both before the work starts and after job was completed; and • Use of lockout/tagout procedures for equipment that was undergoing maintenance. The CSB found evidence of breakdowns in both the work order and lockout/tagout programs that contributed to the incident. Although the work order procedure required a signature before work commenced and after the work had been completed, operators reported that maintenance personnel did not always obtain production operators’ signatures as required. Additionally, work order documentation was not kept at production control stations. Operators used the lockout/tagout procedures to manage the work on the heat exchanger rupture disk, but did not clearly document the progress and status of the maintenance. Information that the isolation valve on the safety relief vent remained in the closed position and locked out was limited to a handwritten note. Although maintenance workers had replaced the rupture disk by about 4:30 p.m. on June 10, the valve isolating the rupture disk was not reopened. No further activities

- 40. involving the rupture disk or relief line occurred on the nightshift or the dayshift on June 11 and the valve remained closed. Figure 3 shows the timeline of these events. Goodyear’s work order system for maintenance requires the process operator to sign off when the repairs are completed. However, whether this occurred during the June 10 dayshift is unclear, and Goodyear was unable to produce a signed copy of the work order. Goodyear Houston Case Study January 2011 7 Figure 3. Event timeline 3.3 Pressure Vessel Over- pressure Protection 3.3.1 Heat Exchanger Rupture As Figure 2 shows, a rupture disk and a pressure relief valve in series protected the ammonia heat exchanger from over- pressure. An isolation valve installed

- 41. between the rupture disk and the heat exchanger isolated the rupture disk and relief valve for maintenance. However, when the valve was in the closed position, the heat exchanger was still protected from an over-pressure condition by the automatic pressure control valve. The next day, when operators began a separate task to steam clean the process piping they closed a block valve between the heat exchanger and the automatic pressure control valve. This isolated the ammonia side of the heat exchanger from all means of over-pressure protection. Steam flowing through the heat exchanger increased the ammonia temperature and the pressure in the isolated heat exchanger. Because the over-pressure protection remained isolated, the internal pressure increased until the heat exchanger suddenly and catastrophically ruptured. 3.3.2 Pressure Vessel Standards The American Society of Mechanical Engineers Boiler and Pressure Vessel Code, Section VIII (the ASME Code), provides rules for pressure vessel design, use, and maintenance, including over- pressure protection. Use of the ASME Code was required at Goodyear by OSHA’s 29 CFR 1910.119 Process Safety Management Standard.1

- 42. The ASME Code requires that when a pressure vessel relief device is temporarily blocked and there is a possibility of vessel pressurization above the design limit, a worker capable of releasing the pressure must continuously monitor the vessel. Goodyear’s maintenance procedures did not address over-pressurization by the ammonia when the relief line was blocked, nor did it require maintenance and operations staff to post a worker at the vessel to open the isolation valve if the pressure increased above the operating limit. 1 OSHA Process Safety Management regulation, 29 CFR 1910.119, is a performance-based process- safety regulation requiring manufacturers to comply with recognized and generally accepted good engineering practices on processes containing greater than threshold quantities of toxic or flammable chemicals. Goodyear Houston Case Study January 2011 8 4.0 Lessons Learned 4.1 Worker Headcounts

- 43. On the morning of the incident, Goodyear erroneously accounted for all its workers and declared an end to the emergency. Hours later, workers discovered the victim buried in the rubble near the ruptured vessel. Her absence had not been noted due to lack of training and drills on worker headcounts. Companies should conduct worker headcount drills that implement their emergency response plans on a facility- wide basis. Company procedures must account for breakdowns in automated worker tracking systems to ensure that all workers inside a facility can be quickly accounted for in an emergency. Drills that simulate such malfunctions should be conducted to verify that all lines of responsibility and alternate verification techniques will account for workers in a real situation. 4.2 Maintenance Completion Although maintenance workers had replaced the rupture disk by about 4:30 p.m. on June 10, the primary over- pressure protection for the heat exchanger remained isolated until the heat exchanger ruptured at about 7:30 a.m. on June 11. Communicating plant conditions between

- 44. maintenance and operations personnel is critical to the safe operation of a process plant. Good practice includes formal written turnover documents that inform maintenance personnel when a process is ready for maintenance and operations personnel when maintenance is completed and the process can be safely restored to operation. 4.3 Isolating Pressure Vessels Goodyear employees completely isolated an ammonia heat exchanger, including the over-pressure protection, while steaming a process line through the heat exchanger. Workers left the pressure relief line isolated for many hours following completion of the maintenance. In accordance with the ASME Boiler and Pressure Vessel Code, over-pressure protection shall be continuously provided on pressure vessels installed in process systems whenever there is a possibility that the vessel can be over-pressurized by any pressure source, including external mechanical pressurization, external heating, chemical reaction, and liquid-to- vapor expansion. Workers should continuously monitor an isolated pressure relief system throughout the course of a repair and reopen blocked valves immediately after the work is completed.

- 45. Goodyear Houston Case Study January 2011 9 5.0 References Occupational Safety and Health Administration (OSHA) Process Safety Management Standard. 29 CFR 1910.119, 1992. American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code, Section VIII, Division I, 2004. Center for Chemical Process Safety (CCPS). Plant Guidelines for Technical Management of Chemical Process Safety (revised ed.). American Institute of Chemical Engineers (AIChE), 2004. CCPS. Guidelines for Engineering Design for Process Safety, AIChE, 1993, p. 539. Goodyear Houston Case Study January 2011 10

- 46. The U.S. Chemical Safety and Hazard Investigation Board (CSB) is an independent Federal agency whose mission is to ensure the safety of workers, the public, and the environment by investigating and preventing chemical incidents. The CSB is a scientific investigative organization; it is not an enforcement or regulatory body. Established by the Clean Air Act Amendments of 1990, the CSB is responsible for determining the root and contributing causes of accidents, issuing safety recommendations, studying chemical safety issues, and evaluating the effectiveness of other government agencies involved in chemical safety. No part of the conclusions, findings, or recommendations of the CSB relating to any chemical accident may be admitted as evidence or used in any action or suit for damages. See 42 U.S.C. § 7412(r)(6)(G). The CSB makes public its actions and decisions through investigation reports, summary reports, safety bulletins, safety recommendations, case studies, incident digests, special technical publications, and statistical reviews. More information about the CSB is available at www.csb.gov. CSB publications can be downloaded at www.csb.gov or obtained by contacting: U.S. Chemical Safety and Hazard Investigation Board Office of Congressional, Public, and Board Affairs 2175 K Street NW, Suite 400 Washington, DC 20037-1848

- 47. (202) 261-7600 CSB Investigation Reports are formal, detailed reports on significant chemical accidents and include key findings, root causes, and safety recommendations. CSB Hazard Investigations are broader studies of significant chemical hazards. CSB Safety Bulletins are short, general-interest publications that provide new or noteworthy information on preventing chemical accidents. CSB Case Studies are short reports on specific accidents and include a discussion of relevant prevention practices. All reports may contain safety recommendations when appropriate. http://www.csb.gov/�Introduction1.0 Incident Description2.0 Background2.1 Goodyear2.1.1 Process Description2.1.2 Ammonia Heat Exchangers2.2 Ammonia Properties3.0 Analysis3.1 Emergency Procedures3.1.1 Onsite Emergency Response Training3.1.2 Plant Alarm System3.1.3 Accounting for Workers in an Emergency3.2 Maintenance Procedures3.3 Pressure Vessel Over-pressure Protection3.3.1 Heat Exchanger Rupture3.3.2 Pressure Vessel Standards4.0 Lessons Learned4.1 Worker HeadcountsOn the morning of the incident, Goodyear erroneously accounted for all its workers and declared an end to

- 48. the emergency. Hours later, workers discovered the victim buried in the rubble near the ruptured vessel. Her absence had not been noted due to la...Companies should conduct worker headcount drills that implement their emergency response plans on a facility-wide basis. Company procedures must account for breakdowns in automated worker tracking systems to ensure that all workers inside a facility c...4.2 Maintenance CompletionAlthough maintenance workers had replaced the rupture disk by about 4:30 p.m. on June 10, the primary over- pressure protection for the heat exchanger remained isolated until the heat exchanger ruptured at about 7:30 a.m. on June 11.Communicating plant conditions between maintenance and operations personnel is critical to the safe operation of a process plant. Good practice includes formal written turnover documents that inform maintenance personnel when a process is ready for ma...4.3 Isolating Pressure VesselsGoodyear employees completely isolated an ammonia heat exchanger, including the over-pressure protection, while steaming a process line through the heat exchanger. Workers left the pressure relief line isolated for many hours following completion of t...In accordance with the ASME Boiler and Pressure Vessel Code, over-pressure protection shall be continuously provided on pressure vessels installed in process systems whenever there is a possibility that the vessel can be over-pressurized by any pressu...5.0 References Unit VII Case Study: Heat Exchanger Rupture Incident Review the attached Chemical Safety Board’s (CSB) Case Study on the 2008 Goodyear Heat Exchanger Rupture incident.

- 49. 1. Using the information in the CSB Case Study, identify probable direct causes, contributing causes, and root causes of the incident. Explain the reasoning you used to reach these causes. You may make assumptions concerning any missing investigative information as long as you clearly state your assumptions. Discuss how and where your proposed causal factors fit into the causation model (attached). For the root causes only, provide recommended corrective actions. 2. Create an Events and Causal Factors chart that follows the timeline of the incident. Be sure to include all causal factors you identified in your discussion, as well as any other conditions and events that are relevant to understanding the accident sequence. The chart can be created using MS-Word, PowerPoint, or Excel, or it can be hand drawn and scanned. The completed case study must be a minimum of three pages

- 50. and maximum of five pages, not including the title page, reference page, and chart. Use APA formatting for all of your assignment, as well as for all references and in-text citations. Unit VII Assessment Questions: 1. Discuss the worksite inspection process in use at your current organization or at an organization with which you are familiar. Who conducts the inspections? How are the results communicated? Are actions taken to resolve deficiencies? Are deficiencies tracked until resolved? Based on best practices in the current

- 51. safety literature, what would you recommend to improve the process? Your response must be at least 300 words in length. All sources used, including the textbook, must be referenced; paraphrased and quoted material must have accompanying citations. 2. Conduct an informal safety inspection of a section of your current workplace. Use a checklist you developed yourself, or one that you found in a textbook, journal article, or on the Internet. Conduct this initial inspection by yourself. Compile a list of the hazards you identified (controlled and uncontrolled). Conduct the inspection again, but for the second inspection, talk to one or more employees about their perception of the hazards to which they are exposed, in addition to using the checklist, compile a second list of hazards and compare it to the first. If they are different, provide some possible explanations for the differences. If they are the same, does that mean you have identified

- 52. all the hazards? (If you are not currently working, see if you can get a local business to allow you to do the “inspection.”) Your response must be at least 300 words in length. All sources used, including the textbook, must be referenced; paraphrased and quoted material must have accompanying citations.