HSE Weekly Safety Review

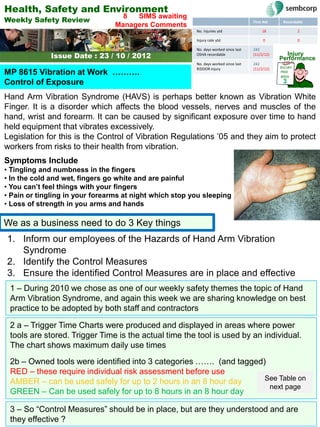

- 1. Health, Safety and Environment 8 SIMS awaiting Weekly Safety Review First Aid Recordable Managers Comments No. injuries ytd 18 2 Injury rate ytd 0 0 No. days worked since last 242 Issue Date : 23 / 10 / 2012 OSHA recordable (11/2/12) Injury Performance No. days worked since last 242 INJURY RIDDOR injury (11/2/12) MP 8615 Vibration at Work ………. FREE WEEK Control of Exposure 3 Hand Arm Vibration Syndrome (HAVS) is perhaps better known as Vibration White Finger. It is a disorder which affects the blood vessels, nerves and muscles of the hand, wrist and forearm. It can be caused by significant exposure over time to hand held equipment that vibrates excessively. Legislation for this is the Control of Vibration Regulations ’05 and they aim to protect workers from risks to their health from vibration. Symptoms Include • Tingling and numbness in the fingers • In the cold and wet, fingers go white and are painful • You can’t feel things with your fingers • Pain or tingling in your forearms at night which stop you sleeping • Loss of strength in you arms and hands We as a business need to do 3 Key things 1. Inform our employees of the Hazards of Hand Arm Vibration Syndrome 2. Identify the Control Measures 3. Ensure the identified Control Measures are in place and effective 1 – During 2010 we chose as one of our weekly safety themes the topic of Hand Arm Vibration Syndrome, and again this week we are sharing knowledge on best practice to be adopted by both staff and contractors 2 a – Trigger Time Charts were produced and displayed in areas where power tools are stored. Trigger Time is the actual time the tool is used by an individual. The chart shows maximum daily use times 2b – Owned tools were identified into 3 categories ……. (and tagged) RED – these require individual risk assessment before use See Table on AMBER – can be used safely for up to 2 hours in an 8 hour day next page GREEN – Can be used safely for up to 8 hours in an 8 hour day 3 – So “Control Measures” should be in place, but are they understood and are they effective ?

- 2. The procedure requires each work group to……. • Identify all the vibrating tools in their area and put them in a register Has your team any power tools ? If so, have you a register ? • Assess the level of vibration each tool produces Have all tools on your register been assessed ? • Place the correct coloured sticker on the equipment Are all your tools marked with the correct colour tag ? Contact the safety department to help carry out your survey if you need to do so TYPE OF TOOL CATEGORY MAXIMUM TRIGGER TIME (used in Sembcorp) Sticker colour Grinders < 6” Internal Grinders 8 hours in any 8 hour period. Tools Normal Drills A that vibrate up to 5 metres per Power Saws second squared (m/s²) Engravers Strimmers Grinders > 6” 2 hours in any 8 hour period. Tools Hammer Drills B that vibrate up to 10 m/s² Chain Saws Tools that vibrate over 10 m/s² must Impact Guns be assessed on our “Guide to Needle Guns C Vibration” chart to identify usage Impact Chisels time, or contact your supervisor or the safety department For Guidance - Power tools we use at home can also produce harmful levels of vibration ……………….. A typical mains hedge cutter would be categorised B if used at work A typical drill used on hammer action would be categorised B at work A typical mains power jig saw would be categorised C at work Be careful how long you use these tools for !