Watch PPT On SAP EWM Wave Management.

https://www.usaonlinetrainings.com/sap-s4hana-ewm/

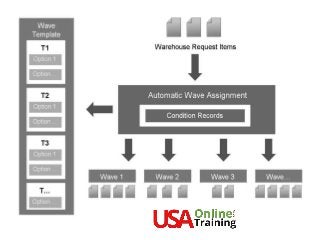

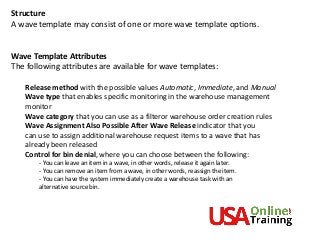

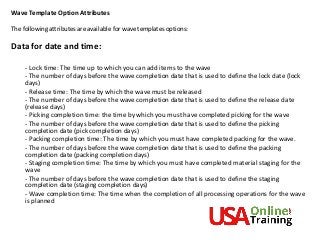

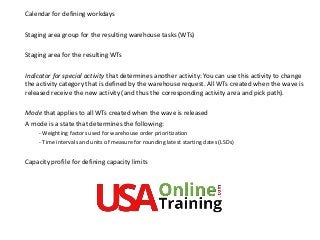

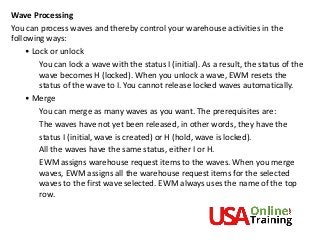

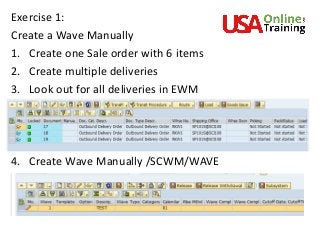

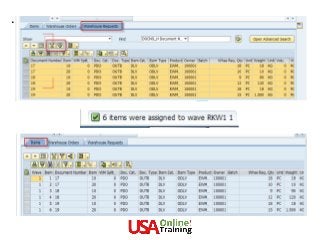

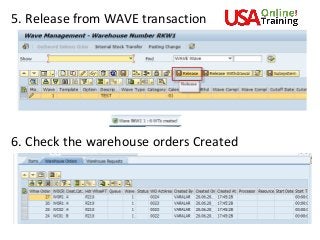

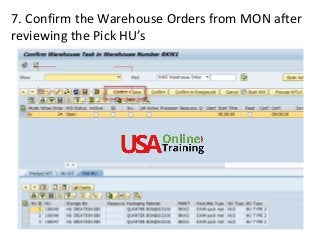

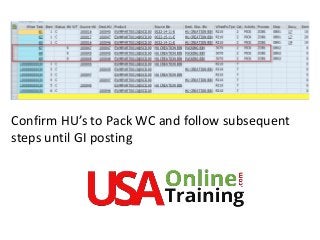

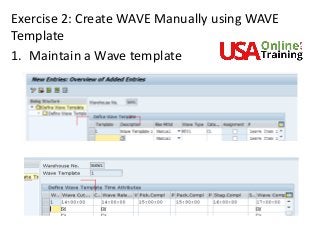

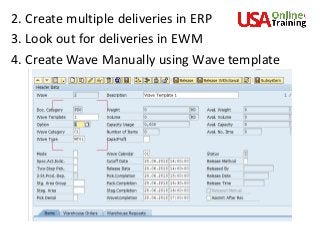

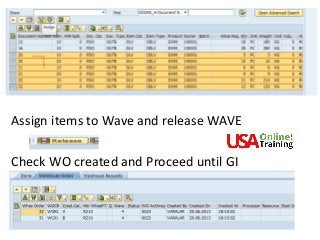

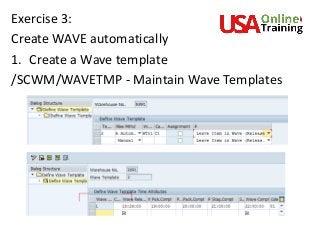

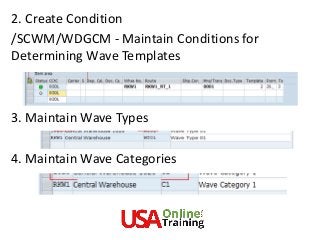

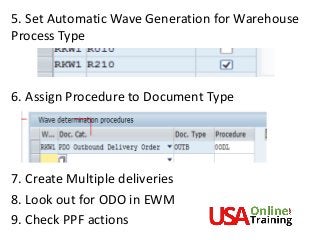

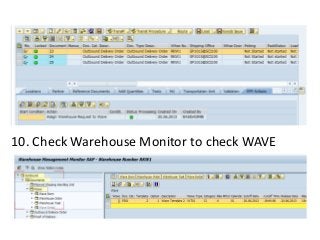

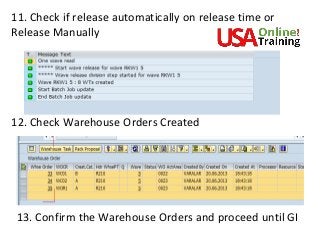

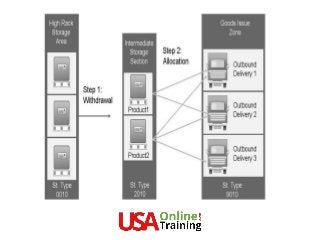

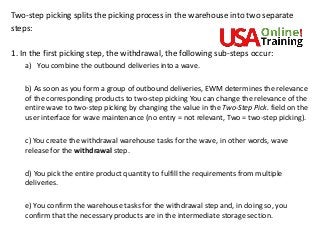

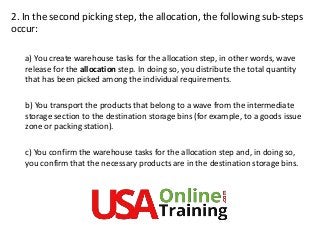

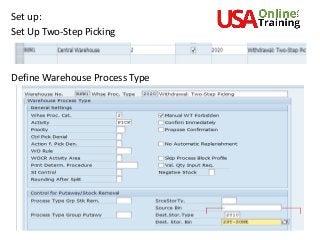

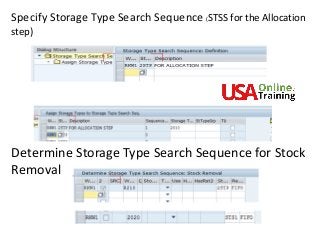

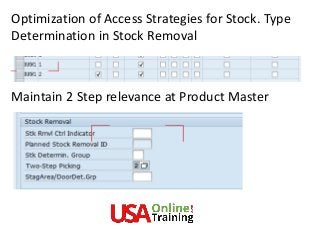

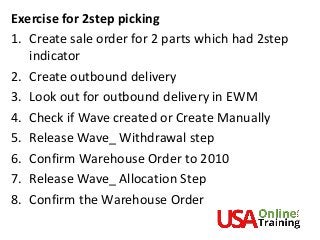

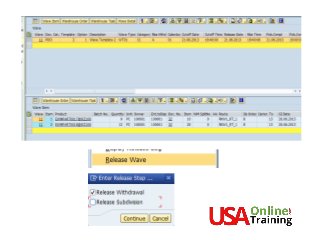

assign items to wave and release wave,create wave manually,ewm automatic wave creation,ewm high rack storage area,ewm intermediate storage section,ewm wave category,ewm wave maintain,ewm wave template date and time,ewm wave transaction,how to process ewm wave process,remove assignment in sap ewm,sap ewm automatic wave assignment,sap ewm goods issue zone,sap ewm manually waves creation,sap ewm warehouse request items,sap ewm wave create immediately,sap ewm wave item clearing,sap ewm wave management,sap ewm wave picking configuration,sap ewm wave planning,sap ewm wave release,sap ewm wave simulation,sap ewm wave template,sap ewm wave templates,sap ewm waves,separate warehouse processes,warehouse monitor to check wave,wave allocation step,wave assignement after release,wave delete in sap ewm,wave template attribute,wave withdrawal warehouse task