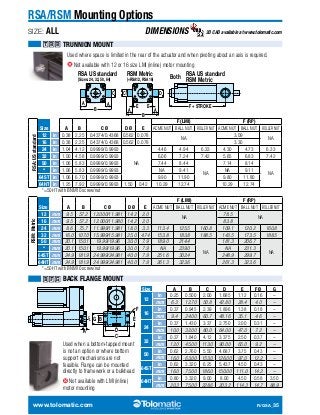

RSA/RSM Rod Actuator is a High Performance Electric Actuator Available in 6 Sizes

The RSA/RSM electric rod actuators offer the most complete selection of sizes, options and system components. Designed with high performance, high thrust, dependability and mounting flexibility in mind, the RSA/RSM electric rod actuator offers a cost-competitive solution for a multitude of motion control applications.

6 body sizes

35 different screw selections

Thrust capabilities up to 12,900 lbf (57,392 N)

Strokes in any incremental length up to 60 in (1,524 mm)

US conventional and metric versions

![RSA & GSA Electric Rod-Style Actuator

WHAT ARE THE RSA & THE GSA?

Flexibility defines the RSA and the GSA. Need a basic electric screw-driven rod-style actuator? Choose the RSA. Need a rod

style actuator that provides guidance and support for the load? Choose the GSA. Every actuator is built-to-order in the stroke

length you specify, shipped in 15 days or less. Motors can be mounted inline or reverse parallel to shorten the actuator.

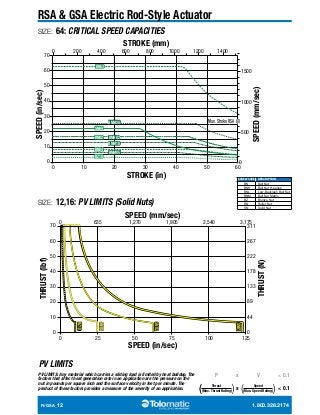

Tolomatic offers brushless servo and stepper motors or supply your own motor and take advantage of our “Your Motor Here”

(YMH) program. Choose from 3 drive screw technologies with 12 different mounting and rod end options. All this backed by

over 50 years experience and our 100% satisfaction guarantee.

RP

MP2

LMI

GSA

FM2

RSA

CK

FFG

TRR

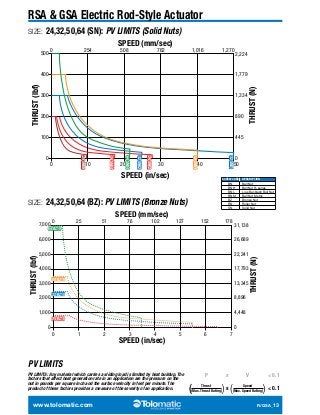

PCS

PCD

R/GSA_2 1.800.328.2174

BFG

YMH

YMH

ALC

CLV

MET

SRE

THE MODULAR FLEXIBLE DESIGN OF THE RSA & GSA, BUILT-TO-ORDER IN 15 DAYS

TOLOMATIC’S ELECTRIC ROD-STYLE ACTUATORS

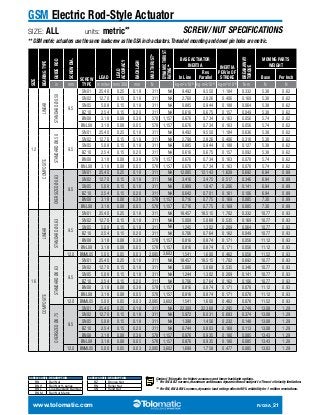

ERD ICR RSA GSA IMA

Rod-Style Actuator Integrated Control

Rod-Style Actuator

Rod-Style Actuator Guided Rod-Style

Actuator

Integrated Motor

Rod-Style Actuator

Thrust up to: 4,500 lbf

[20,017 N]

720 lbf

[3,202.7 N]

12,900 lbf

[57,382 N]

4,159 lbf

[18,500 N]

6,875 lbf

[30,594 N]

Speed up to: 58 in/sec

[1473 mm/sec]

25 in/sec

[635 mm/sec]

123 in/sec

[3,124 mm/sec]

123 in/sec

[3,124 mm/sec]

52.5 in/sec

[1,334 mm/sec]

Stroke Length

up to:

39.4 in

[1000 mm]

24 in

[609 mm]

60 in

[1,524 mm]

36 in

[914 mm]

18 in

[457 mm]

Screw/Nut Type Solid, Ball & Roller Ball Solid, Ball & Roller Solid & Ball Ball & Roller

For complete information see www.tolomatic.com or literature number:

Literature Number: 2190-4000 2100-4000 3600-4609 3600-4609 2700-4000

(Not all models deliver maximum values listed, i.e.: Maximum thrust may not be available with maximum speed)](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-2-320.jpg?cb=1414404811)

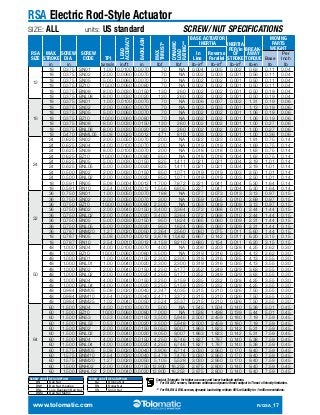

![RSA Rod-Style Screw Driven Actuator

SIZE: ALL

DIMENSIONS 3D CAD available at www.tolomatic.com

F

B AA

G+

CC

K

A

RR

D C

L

J

Motor

Motor

H+

STROKE

F E

STROKE

BB

EE EE

SS SS

G+

STROKE

K

J

SS

DD FF DD DD FF

DD

GG

E

LMI Motor Mount

H+STROKE

SS

JJ JJ

LL

HH

CL

RP Motor Mount

MM

KK

NN

Ø PP

Stub Shaft

LL

Motor

Motor

Motor

KK

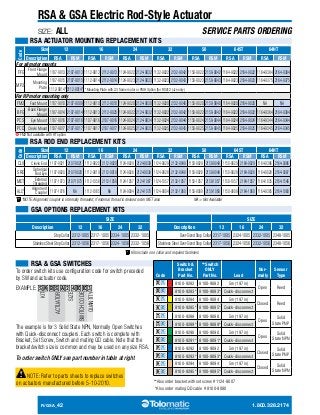

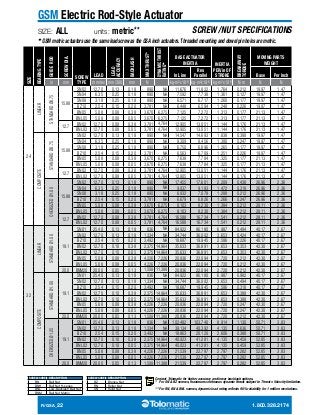

Size G H

16

See table

at right for

BNML05

dimensions

*For

BN08

BNL08

only.

ACME NUT BALL NUT ROLLER NUT

BNML05

in 2.51 3.37

mm 63.8 85.6

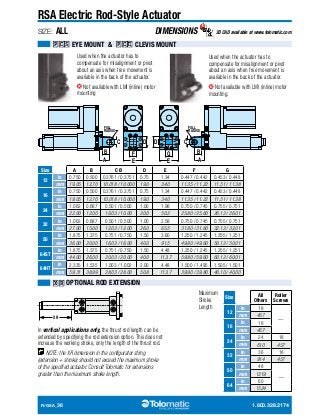

ST ACTUATOR DIMENSIONS

Size A B C [4x] D E [2x] F G H G H G H J Ø K RR SS (2)

R/GSA_28 1.800.328.2174

12

in 0.906 0.391 5-40 0.50 1/4-28 0.75 8-32 0.25 0.81 2.17 2.76 2.17 2.76 NA NA 0.56 0.31 0.56 NA

mm 23.01 9.93 M3x0.5 12.7 M6x1.0 19 M4x0.7 6.3 20.7 55.1 70.1 55.1 70.1 NA NA 14.2 7.8 14.3 NA

16

in 0.500 1.063 8-32 0.50 5/16-24 0.75 8-32 0.25 1.06 2.13 2.99 2.13* 2.99* NA NA 0.69 0.43 0.69 NA

mm 12.70 27.00 M4x0.7 12.7 M8x1.25 19 M4x0.7 6.3 26.9 54.2 75.9 54.2* 75.9* NA NA 17.5 10.9 17.5 NA

24

in 0.875 1.603 10-24 0.79 7/16-20 1.00 1/4-20 0.33 1.11 2.90 3.84 3.36 4.30 4.54 5.21 1.18 0.43 1.96 NA

mm 22.23 40.72 M5x0.8 20.0 M10x1.25 25.0 M6x1.0 8.6 28.2 73.7 97.5 85.4 109.2 115.2 132.3 30.0 10.9 49.8 NA

32

in 1.181 1.969 1/4-20 0.70 7/16-20 1.13 5/16-18 0.47 1.43 3.87 5.05 5.05 6.23 6.05 6.85 1.25 0.50 1.29 1/16-27 NPT

mm 30.00 50.00 M6x1.0 18.0 M16x1.5 26.0 M8x1.25 12.0 36.3 98.4 128.3 128.3 158.2 153.6 174.0 31.8 12.7 32.8 1/16-27 NPT

50

in 1.969 3.000 5/16-18 1.00 3/4-16 1.50 3/8-16 0.75 1.95 4.78 6.44 5.78 7.44 NA NA 1.75 0.70 1.86 1/8-27 NPT

mm 50.00 76.20 M8x1.25 25.4 M20x1.5 38.0 M10x1.5 19.0 49.5 121.5 163.6 146.9 189.0 NA NA 44.5 17.8 47.1 1/8-27 NPT

64

in 1.969 3.500 7/16-14 1.50 3/4-16 1.50 7/16-14 0.88 2.37 6.94 8.90 8.94 10.90 NA NA 2.25 0.68 2.29 1/8-27 NPT

mm 50.00 88.90 M12x1.75 38.1 M27x2.0 38.0 M12x1.75 22.2 60.2 176.2 226.1 227.0 276.9 NA NA 57.2 17.3 58.2 1/8-27 NPT](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-28-320.jpg?cb=1414404811)

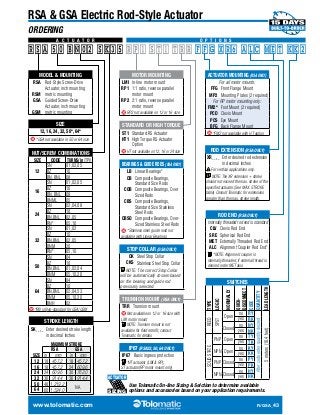

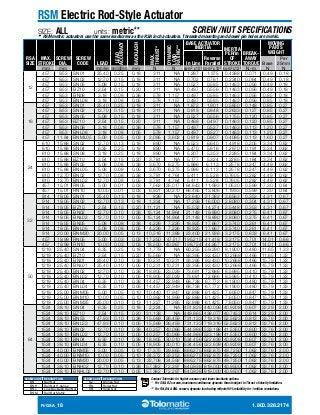

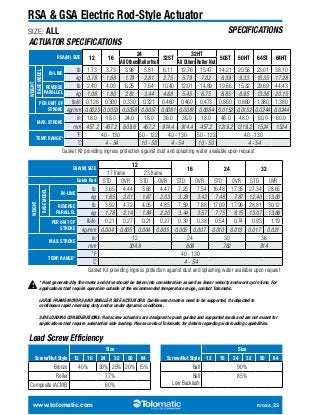

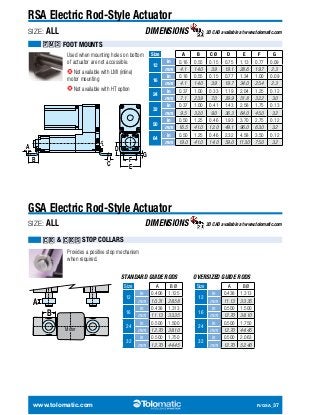

![RSA Rod-Style Screw Driven Actuator

DIMENSIONS 3D CAD available at www.tolomatic.com

ROLLER NUTS ALL OTHER NUTS

MM∞ NN PP

GG HH JJ KK∞ LL∞ GG HH JJ KK∞ LL∞

ST ACTUATOR DIMENSIONS

in 1.34 3.92 2.57 NA 1.13 0.500 8-32 0.25 NA NA NA 1.66 1.85 1.66 0.72 1.66 1.85 2.26 0.61 Ø.188

mm 34.1 99.6 65.3 NA 28.6 12.70 M4x0.7 6.3 NA NA NA 42.0 47.0 42.1 18.3 42.0 47.0 57.3 15.5 4.78

in 1.34 3.92 2.57 NA 1.13 0.500 8-32 0.25 NA NA NA 2.00 1.85 1.66 0.72 2.00 2.49 2.26 0.61 Ø.188

mm 34.1 99.6 65.3 NA 28.6 12.70 M4x0.7 6.3 NA NA NA 50.8 47.0 42.1 18.3 50.8 63.2 57.3 15.5 4.78

in 1.34 4.04 2.64 NA 1.38 0.500 8-32 0.25 NA NA NA 2.25 2.39 1.66 0.72 2.25 2.49 2.26 0.61 Ø.188

mm 34.1 102.7 67.0 NA 35.0 12.70 M4x0.7 6.3 NA NA NA 57.2 60.7 42.1 18.3 57.2 63.2 57.3 15.5 4.78

in 2.04 5.13 3.68 3.65 2.04 0.787 1/4-20 0.31 4.25 2.25 2.25 2.35 3.28 2.28 1.66 1.42 2.35 2.55 2.50 0.55 Ø.315

mm 51.8 130.2 93.4 92.6 51.8 19.98 M6x1.0 8.6 107.8 57.2 57.2 59.7 83.3 57.9 42.2 36.0 59.7 64.8 63.5 14.0 8.00

in 2.04 6.29 4.09 4.06 2.04 0.787 1/4-20 0.31 4.25 2.00 2.25 3.75 3.28 2.87 2.00 1.42 3.75 3.28 3.79 0.55 Ø.315

mm 51.8 159.8 103.9 103.2 51.8 19.98 M6x1.0 8.6 107.8 50.7 57.2 95.3 83.3 72.8 50.7 36.0 95.3 83.3 96.3 14.0 8.00

in 2.58 5.89 4.18 4.20 2.58 0.950 5/16-18 0.50 4.87 2.00 2.88 3.39 3.68 3.19 2.00 1.79 3.00 2.63 2.58 0.69 Ø.394

mm 65.5 149.6 106.1 106.7 65.5 24.13 M8x1.25 12.7 123.7 50.7 73.0 86.1 93.3 80.9 50.7 45.4 76.2 66.8 65.5 17.5 10.00

in 2.58 7.52 5.03 5.00 2.58 0.950 5/16-18 0.50 4.87 2.00 2.88 3.75 3.70 3.19 2.00 1.79 3.75 2.38 4.25 0.69 Ø.394

mm 65.5 190.9 127.8 126.9 65.5 24.13 M8x1.25 12.7 123.7 50.7 73.0 95.3 93.9 80.9 50.7 45.4 95.3 60.5 108.0 17.5 10.00

in 3.71 8.51 6.28 6.24 3.71 1.18 3/8-16 0.68 NA NA NA 3.00 3.30 3.60 2.22 2.13 3.00 3.30 3.69 1.36 Ø.500

mm 94.2 216.2 159.6 158.5 94.1 30.0 M10x1.5 17.5 NA NA NA 76.2 83.8 91.3 56.3 54.0 76.2 83.8 93.7 34.5 12.70

in 3.71 8.51 6.28 6.24 3.71 1.18 3/8-16 0.68 NA NA NA 3.00 3.05 3.60 2.27 2.13 3.95 3.05 3.69 1.36 Ø.500

mm 94.2 216.2 159.6 158.5 94.1 30.0 M10x1.5 17.5 NA NA NA 76.2 63.5 91.3 57.5 54.0 100.2 63.5 93.7 34.5 12.70

in 3.71 9.50 6.78 6.73 3.71 1.18 3/8-16 0.68 NA NA NA 3.00 4.48 3.60 2.52 2.13 5.00 4.48 5.58 1.36 Ø.500

mm 94.2 241.3 172.1 171.1 94.1 30.0 M10x1.5 17.5 NA NA NA 76.2 77.4 91.3 63.9 54.0 127.0 77.4 141.7 34.5 12.70

in 4.73 8.84 6.72 6.82 4.58 1.97 3/8-16 0.68 NA NA NA 3.75 3.05 4.73 2.75 3.48 3.75 3.05 4.48 1.36 Ø.750

mm 120.2 224.6 170.7 173.2 116.3 50.0 M10x1.5 17.5 NA NA NA 95.2 77.5 120.2 69.9 88.3 95.2 77.5 113.8 34.5 19.05

in 4.73 10.05 7.21 7.12 4.58 1.97 3/8-16 0.68 NA NA NA 5.00 4.48 4.73 2.85 3.48 5.00 4.48 5.73 1.36 Ø.750

mm 120.2 225.3 183.1 180.8 116.3 50.0 M10x1.5 17.5 NA NA NA 127.0 113.8 120.2 72.4 88.3 127.0 113.8 145.5 34.5 19.05

∞NOTE: YM code may change this dimension.

Always use configured CAD to determine critical dimensions

Size

Motor

Frame

AA BB

CC

1:1

CC

2:1

DD EE FF [2x]

12

17

23

16 23

24

23

34

32

23

34

50

23

34

56

64

34

56

HT ACTUATOR DIMENSIONS

Size

Motor

Frame

C [6x] BZ10 BALL NUTS BNM05/25

AA BB

CC

1:1

CC

2:1

GG KK∞ LL∞ MM∞ RR

C [4x] D G H G H G H L

32

23

in 1/4-20 0.70 7/16-20 1.13 NA NA 5.05 6.23 NA NA NA 2.58 5.89 4.83 4.80 3.19 3.46 4.14 2.58 1.29

mm M6x1.0 18.0 M16x1.5 28.7 NA NA 128.3 158.2 NA NA NA 65.5 149.6 122.8 121.8 80.9 87.9 105.1 65.5 32.8

34

in 1/4-20 0.70 7/16-20 1.13 NA NA 5.05 6.23 NA NA NA 2.58 5.89 4.83 4.80 3.19 3.55 4.10 4.25 1.29

mm M6x1.0 18.0 M16x1.5 28.7 NA NA 128.3 158.2 NA NA NA 65.5 149.6 122.8 121.8 80.9 90.0 104.2 108.0 32.8

50

34

in 5/16-18 1.00 3/4-16 1.45 NA NA 6.75 8.41 5.78 7.44 NA 3.71 8.51 6.68 6.62 NA 4.56 5.36 3.69 1.86

mm M8x1.25 25.4 M20x1.5 36.8 NA NA 171.5 213.6 146.9 189.0 NA 94.2 216.2 169.6 168.1 NA 115.8 136.2 93.7 47.1

56

in 5/16-18 1.00 3/4-16 1.45 NA NA 6.75 8.41 5.78 7.44 NA 3.71 9.50 6.68 6.62 NA 4.88 5.41 5.58 1.86

mm M8x1.25 25.4 M20x1.5 36.8 NA NA 171.5 213.6 146.9 189.0 NA 94.2 241.3 169.6 169.6 NA 123.8 137.4 141.7 47.1

64

34

in 1/2-13 0.75 1-1/4-12 2.50 7.80 9.29 10.25 11.74 NA NA 3.50 6.88 12.1 8.81 8.75 7.75 5.90 5.88 6.88 3.30

mm M12x1.75 18.0 M27x2.0 63.5 198.0 235.9 260.3 298.2 NA NA 88.9 174.6 306.1 223.8 222.3 196.9 149.9 149.3 174.6 83.8

56

in 1/2-13 0.75 1-1/4-12 2.50 7.80 9.29 10.25 11.74 NA NA 3.50 6.88 12.1 8.81 8.75 7.75 5.90 5.88 6.88 3.30

mm M12x1.75 18.0 M27x2.0 63.5 198.0 235.9 260.3 298.2 NA NA 88.9 174.6 306.1 223.8 222.3 196.9 149.9 149.3 174.6 83.8

Indicates dimensions are the same as ST1 actuators

www.tolomatic.com R/GSA_29](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-29-320.jpg?cb=1414404811)

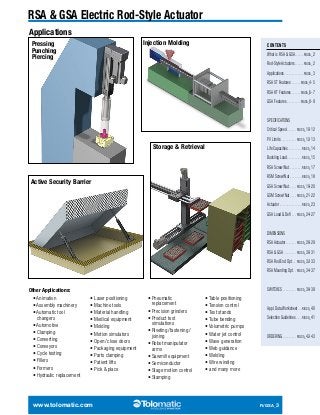

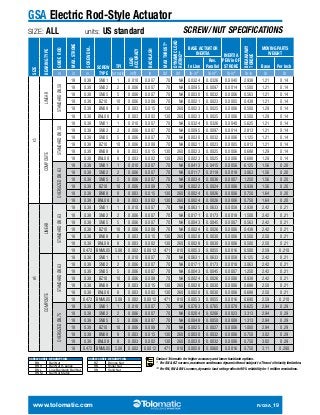

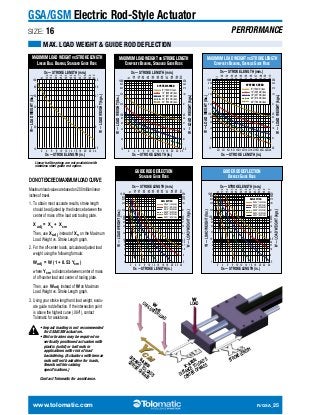

![GSA Electric Rod-Style Actuator

SIZE: ALL DIMENSIONS 3D CAD available at www.tolomatic.com

Y+

CC

CL CL

GG

D

A

B C

K L

EE

FF

W

V

N

R

P

S

T

X

M

U

JJ JJ

LL

HH

MM

Motor

Motor

Motor

Motor

R/GSA_30 1.800.328.2174

H

G

F

J

E

KK KK LL

BB

LMI Motor Mount RP Motor Mount

DD DD

CL

STROKE

CL CL

EE

FF

DD MM DD

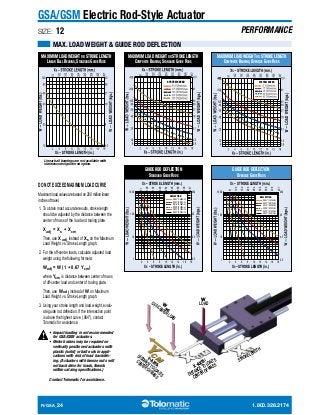

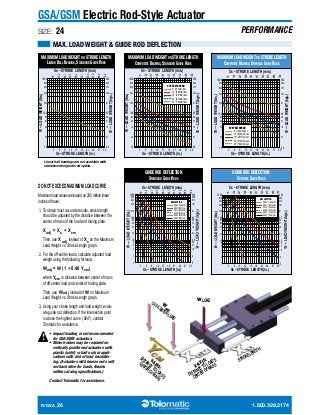

Size A B C [4x] D E F G H J [4x]

12

in 5.13 2.000 1/4-20 Ø.38 0.22 OPP 0.688 0.88 4.00 2.500 0.750 Ø.266 Thru Ø.44 0.28 5/16-18 0.75 OPP

mm 130.2 50.80 M6x1.0 Ø9.5 5.6 OPP 17.46 22.4 101.6 63.50 19.05 Ø6.76 Thru Ø11.1 7.1 M8 1.25 OPP

16

in 6.25 2.500 5/16-18 Ø.44 0.28 OPP 1.000 1.13 5.00 2.625 1.188 Ø.266 Thru Ø.44 0.28 5/16-18 0.75 OPP

mm 158.8 63.50 M8x1.25 Ø11.1 7.1 OPP 25.40 28.6 127.0 66.68 30.18 Ø6.76 Thru Ø11.1 7.1 M8 1.25 OPP

24

in 7.75 3.500 5/16-18 Ø.44 0.28 OPP 1.375 1.38 6.00 3.875 1.063 Ø.328 Thru Ø.53 0.34 3/8-16 1.00 OPP

mm 196.9 88.90 M8x1.25 Ø11.1 7.1 OPP 34.93 35.1 152.4 98.43 27.00 Ø8.33 Thru Ø13.5 8.6 M10 1.5 OPP

32

in 10.00 5.000 3/8-16 Ø.53 0.50 OPP 1.750 1.63 7.00 4.125 1.438 Ø.453 Thru Ø.72 0.47 1/2-13 1.50 OPP

mm 254.0 127.00 M10x1.5 Ø13.5 12.7 OPP 44.45 41.4 177.8 104.78 36.51 Ø10.49 Thru Ø18.2 11.9 M12x1.75 OPP](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-30-320.jpg?cb=1414404811)

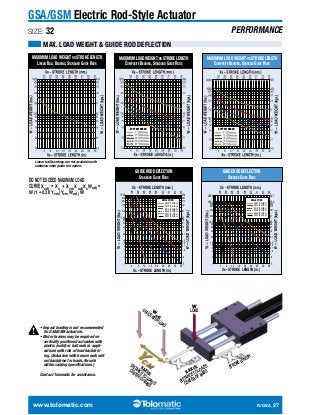

![GSA Electric Rod-Style Actuator

SIZE: ALL DIMENSIONS 3D CAD available at www.tolomatic.com

Size K L M Ø [2x] N P R S T Ø [4x] U V W X Ø [4x] Y

12

in 4.500 2.000 0.375 0.50 1.20 0.297 1.25 1.250 1/4-20 0.50 0.750 1.500 3.406 0.250 0.38 5.68

mm 114.30 50.80 10.00 12.7 30.5 7.54 31.8 31.75 M6x1.0 12.7 19.05 38.10 86.51 6.00 9.5 144.1

16

in 5.438 2.500 0.375 0.50 1.70 0.516 1.75 1.625 1/4-20 0.50 1.000 1.750 3.969 0.250 0.38 6.42

mm 138.13 63.50 10.00 12.7 43.2 13.11 44.5 41.28 M6x1.0 12.7 25.40 44.45 100.81 6.00 9.5 163.1

24

in 7.000 3.000 0.500 0.50 2.15 0.438 2.25 1.625 5/16-18 0.63 1.250 2.750 5.125 0.313 0.50 8.14

mm 177.80 76.20 12.00 12.7 54.6 11.13 57.2 41.28 M8x1.25 16.0 31.75 69.85 130.18 8.00 9.5 206.6

32

in 9.000 3.500 0.500 0.50 2.65 0.594 2.75 2.125 3/8-16 0.75 1.750 2.750 5.812 0.375 0.50 9.81

mm 228.60 88.90 12.00 12.7 67.3 15.09 69.9 53.98 M10x1.5 19.1 44.45 69.85 147.62 10.00 12.7 249.0

∞NOTE: YM

code may

change this

dimension.

Always use

configured

CAD to deter-mine

critical

dimensions

Size

Motor

Frame

AA BB

CC

1:1

CC

2:1

DD EE FF [2x] GG HH JJ KK∞ LL∞ MM∞

12

17

in 1.34 3.92 2.63

mm 34.1 99.5 66.9 28.6 12.70 M4x0.7 6.3 42.1 18.3 42.0 47.0 57.3

in 1.34 3.92 2.63 1.13 0.500 8-32 0.25 1.66 0.72 2.00 2.49 2.26

NA

mm 34.1 99.5 66.9 28.6 12.70 M4x0.7 6.3 42.1 18.3 50.8 63.2 57.3

1.13 0.500 8-32 0.25 1.66 0.72 1.66 1.85 2.26

23

16 23

in 1.34 4.04 2.88 1.38 0.500 8-32 0.25 1.66 0.72 2.25 2.49 2.26

mm 34.1 102.7 73.2 35.0 12.70 M4x0.7 6.3 42.1 18.3 57.2 63.2 57.3

24

23

in 2.04 5.13 3.78 3.75 2.04 0.787 1/4-20 0.31 2.28 1.66 1.42 2.35 2.55 2.50

mm 51.8 130.2 96.1 95.3 51.8 20.00 M6x1.0 8.6 57.9 42.2 36.0 59.7 64.8 63.5

34

in 2.04 6.29 4.20 4.17 2.04 0.787 1/4-20 0.31 2.87 2.00 1.42 3.75 3.28 3.79

mm 51.8 159.8 106.6 105.9 51.8 20.00 M6x1.0 8.6 72.8 50.7 36.0 95.3 83.3 96.3

32

23

in 2.58 5.89 4.26 4.28 2.58 0.950 5/16-18 0.50 3.19 2.00 1.79 3.00 2.63 2.58

mm 65.5 149.6 108.3 108.9 65.5 24.13 M8x1.25 12.7 80.9 50.7 45.4 76.2 66.8 65.5

34

in 2.58 7.52 5.11 5.08 2.58 0.950 5/16-18 0.50 3.19 2.00 1.79 3.75 2.38 4.25

mm 65.5 190.9 129.9 129.0 65.5 24.13 M8x1.25 12.7 80.9 50.7 45.4 95.3 60.5 108.0

www.tolomatic.com R/GSA_31](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-31-320.jpg?cb=1414404811)

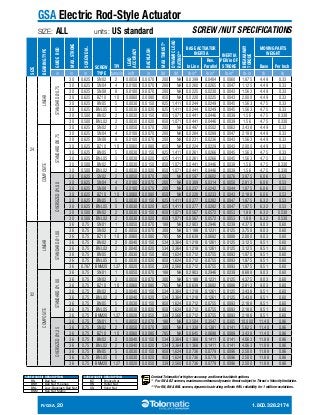

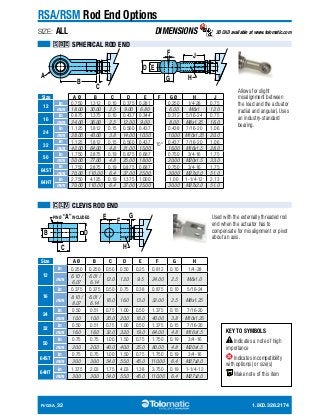

![RSA GSA Electric Rod-Style Actuator

SIZE: ALL

SWITCHES

COMPLIANT

Order

Code

Lead

Switching

Logic

Power

LED

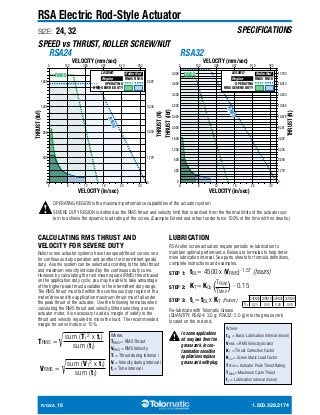

RSA GSA products offer a wide range of sensing choices. There are 12

switch choices: reed, solid state PNP (sourcing) or solid state NPN (sinking);

in normally open or normally closed; with flying leads or quick-disconnect.

Commonly used for end-of-stroke positioning, these switches allow installation

anywhere along the entire actuator length. The internal magnet is a standard feature.

Switches can be installed in the field at any time.

Switches are used to send digital signals to PLC (programmable logic controller), TTL,

CMOS circuit or other controller device. Switches contain reverse polarity protection.

Solid state QD cables are shielded; shield should be terminated at flying lead end.

All switches are CE rated and are RoHS compliant. Switches feature bright red or

yellow LED signal indicators; solid state switches also have green LED power indicators.

Signal

LED

Operating

Voltage

**Power

Rating

(Watts)

Switching

Current

(mA max.)

Current

Consumption

Voltage

Drop

Leakage

Current

Temp.

Range

Shock /

Vibration

RoHS

REED

RY 5m SPST

Normally

Open

— Red

5 - 240

AC/DC

**10.0 100mA — 3.0 V max. —

14

to

158°F

[-10

to

70°C]

50 G /

9 G

RK QD* 81009082

81009082

81009082

— Yellow

81009082

81009082

81009082

81009084

81009084

81009084

81009084

81009084

Green Yellow

81009084

81009088

81009088

81009088

81009088

81009088

81009088

Green Red

81009090

81009090

81009090

81009090

81009090

81009090

81009092

Green Yellow

81009092

81009092

81009092

81009092

81009092

81009094

NY 5m SPST

Normally

Closed

5 - 110

AC/DC

NK QD*

81009094

SOLID

STATE

TY 5m PNP

(Sourcing)

Normally

Open

10 - 30

VDC

**3.0 100mA

20 mA

@

24V

2.0 V max.

0.05 mA

max.

TK QD*

Green Red

81009094

KY 5m NPN

(Sinking)

Normally

Open

KK QD*

81009094

PY 5m PNP

(Sourcing)

Normally

Closed

PK QD*

81009094

HY 5m NPN

(Sinking)

Normally

Closed

HK QD*

81009094

*QD = Quick-disconnect Enclosure classification IEC 529 IP67 (NEMA 6) CABLES: Robotic grade, oil resistant polyurethane jacket, PVC insulation

**WARNING: Do not exceed power rating (Watt = Voltage x Amperage). Permanent damage to sensor will occur.

SWITCH INSTALLATION

Place switch bracket into one of the four slots that run the length of the extruded tube.

Note that there is a cutout on the actuator head (RSA) or tube (GSA) to allow insertion

of the bracket. Insert the switch with the word “Tolomatic” facing up and slide it under

the bracket. Position the bracket with the switch to the exact location desired, then lock

them securely into place by tightening both set screws on the bracket.

R/GSA_38 1.800.328.2174](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-38-320.jpg?cb=1414404811)

![RSA GSA Electric Rod-Style Actuator

SIZE: ALL

SWITCHES

WIRING DIAGRAMS

RY, #8100-9082, • RK, #8100-9083

REED • NORMALLY OPEN

NORMALLY

OPEN

or

NORMALLY

OPEN

NY, #8100-9084, • NK, #8100-9085

REED • NORMALLY CLOSED

NORMALLY

CLOSED

or

NORMALLY

CLOSED

BRN

BLU

BRN

BLU

BRN

BLU

BRN

BLU

+

LOAD -

+

-

+

LOAD

LOAD -

+

-

LOAD

TY, #8100-9088, • TK, #8100-9089

SOLID STATE • NORMALLY OPEN • PNP

NORMALLY

OPEN PNP

(SOURCING)

BRN

BLK

+

SIGNAL

LOAD

BLU -

KY, #8100-9090, • KK, #8100-9091

SOLID STATE • NORMALLY OPEN • NPN

NORMALLY

OPEN NPN

(SINKING)

BRN

BLK

+

SIGNAL

LOAD

BLU -

PY, #8100-9092, • PK, #8100-9093

SOLID STATE • NORMALLY CLOSED • PNP

NORMALLY

CLOSED PNP

(SOURCING)

BRN

BLK

+

SIGNAL

LOAD

BLU -

HY, #8100-9094, • HK, #8100-9095

SOLID STATE • NORMALLY CLOSED • NPN

NORMALLY

CLOSED NPN

(SINKING)

BRN

BLK

+

SIGNAL

LOAD

BLU -

QUICK DISCONNECT MALE PLUG PINOUT #8100-9080 QUICK DISCONNECT

FEMALE SOCKET PINOUT

BLACK BLUE (-)

(SIGNAL)

BROWN (+)

BLACK

(SIGNAL)

BLUE (-)

BROWN (+)

SWITCH DIMENSIONS MOUNTING DIMENSIONS

_ Y - direct connect

DETECTION POINT

SOLID STATE

0.83 [21.1]

DETECTION POINT REED

_ K - QD (Quick-disconnect) switch

1.50 [38.2]

0.63 [16.0]

0.33 [8.4]

197.33 [5012]

This screw secures switch to bracket

This screw secures bracket to actuator

8100-9080 - QD Cable

1.26 [32.1]

.95 [24.1]

Ø.28 [7]

13.68 [347]

M8x1

M8x1

197 [5000]

A 1.50

B

0.29 [7.4]

www.tolomatic.com R/GSA_39

[38.2]

Ø.35

[9]

CAUTION: DO NOT OVERTIGHTEN SWITCH

HARDWARE WHEN INSTALLING

Size

A B

in mm in mm

12 0.68 17.2 0.13 3.3

16 0.77 19.6 0.11 2.9

24 1.06 26.9

0.06 1.5

32 1.31 33.2

50 1.87 47.5

64 2.31 58.6

Dimensions shown in inches [dimensions in brackets millimeters]](https://image.slidesharecdn.com/3600-416601rsa-gsa-141027091805-conversion-gate02/85/Electric-Rod-Actuator-Actuators-RSA-RSM-39-320.jpg?cb=1414404811)