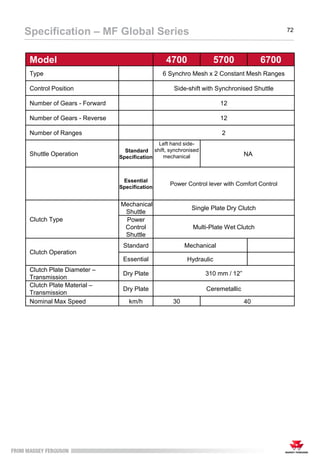

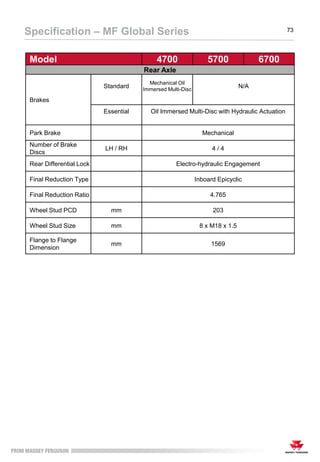

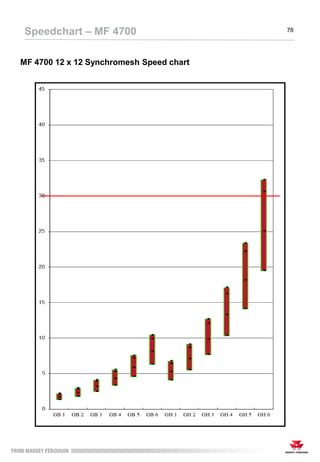

The Massey Ferguson Global Series introduces a new line of tractors designed to replace diverse heritage models, focusing on reliability and ease of operation across various agricultural applications. With engine options from 72 to 132 horsepower and advanced transmission systems, these tractors are engineered for efficiency and performance while supporting a range of farming tasks. The development, backed by over $350 million investment, emphasizes the latest manufacturing techniques and a modular design, showcasing substantial global collaboration in engineering and production.