SKB (Repaired)

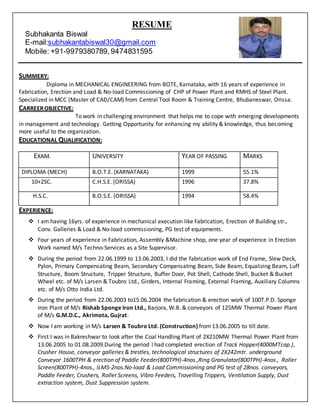

- 1. RESUME Subhakanta Biswal E-mail:subhakantabiswal30@gmail.com Mobile: +91-9979380789,9474831595 SUMMERY: Diploma in MECHANICAL ENGINEERING from BOTE, Karnataka, with 16 years of experience in Fabrication, Erection and Load & No-load Commissioning of CHP of Power Plant and RMHS of Steel Plant. Specialized in MCC (Master of CAD/CAM) from Central Tool Room & Training Centre, Bhubaneswar, Orissa. CARREEROBJECTIVE: To work in challenging environment that helps me to cope with emerging developments in management and technology. Getting Opportunity for enhancing my ability & knowledge, thus becoming more useful to the organization. EDUCATIONAL QUALIFICATION: EXAM. UNIVERSITY YEAR OF PASSING MARKS DIPLOMA (MECH) B.O.T.E. (KARNATAKA) 1999 55.1% 10+2SC. C.H.S.E. (ORISSA) 1996 37.8% H.S.C. B.O.S.E. (ORISSA) 1994 58.4% EXPERIENCE: I am having 16yrs. of experience in mechanical execution like Fabrication, Erection of Building str., Conv. Galleries & Load & No-load commissioning, PG test of equipments. Four years of experience in Fabrication, Assembly &Machine shop, one year of experience in Erection Work named M/s Techno-Services as a Site Supervisor. During the period from 22.06.1999 to 13.06.2003, I did the fabrication work of End Frame, Slew Deck, Pylon, Primary Compensating Beam, Secondary Compensating Beam, Side Beam, Equalizing Beam, Luff Structure, Boom Structure, Tripper Structure, Buffer Door, Pot Shell, Cathode Shell, Bucket & Bucket Wheel etc. of M/s Larsen & Toubro Ltd., Girders, Internal Framing, External Framing, Auxiliary Columns etc. of M/s Otto India Ltd. During the period from 22.06.2003 to15.06.2004 the fabrication & erection work of 100T.P.D. Sponge Iron Plant of M/s Rishab Sponge Iron Ltd., Barjora, W.B. & conveyors of 125MW Thermal Power Plant of M/s G.M.D.C., Akrimota, Gujrat. Now I am working in M/s Larsen & Toubro Ltd. (Construction) from13.06.2005 to till date. First I was in Bakreshwar to look after the Coal Handling Plant of 2X210MW Thermal Power Plant from 13.06.2005 to 01.08.2009.During the period I had completed erection of Track Hopper(4000MTcap.), Crusher House, conveyor galleries & trestles, technological structures of 2X242mtr. underground Conveyor 1600TPH & erection of Paddle Feeder(800TPH)-4nos.,Ring Granulator(800TPH)-4nos., Roller Screen(800TPH)-4nos., ILMS-2nos.No-load & Load Commissioning and PG test of 28nos. conveyors, Paddle Feeder, Crushers, Roller Screens, Vibro Feeders, Travelling Trippers, Ventilation Supply, Dust extraction system, Dust Suppression system.

- 2. Then I was in Asansol to look after RMHS of 2.5Mtpa IISCO Steel Plant from 03.08.2009 to 25.01.2014.During the period I was involved in erection of process buildings like Coke Dedusting Unit, Coke Cushing Station, Coke Screening Station, Coke Breeze Bunker, Coal Blending Bunker (SILO), Coke Loading Station, Sinter Loading Station, transfer buildings, conveyor galleries & trestles, technological structures of 200TPH Conveyors, Mobile Roller Screens, Roll Body Crushers, In-Line Magnetic Separators, Vibro Feeders, Belt Weigh Feeders and installation of Grease Spray Lubrication system, Force Lubrication system of Rod Mill(50TPH each)- 03nos.After completion of structural & equipment erection, I was looked after No-load & Load commissioning of Base Mix Plant having 78nos.Conveyors (TPH varies from 200 to 1200), Hammer Crushers (350TPH)-6nos., Flip Flow Screens (350TPH) - 6nos., Rod Mill (50TPH) - 3nos., Vibro Feeders (TPH varies from 50 to 250) - 36nos., Belt Weigh Feeders (TPH varies from 50 to 1200) - 34nos., In-Line Magnetic Separator- 5nos. I was at Kalinganagar to look after structural fabrication & erection of RMHS of 3MtpaTata Steel Plant from 27.01.2014 to 23.03.2015. I was involved in fabrication of 3500MTStructural Buildings, Conveyor galleries, trestles & 1000MT erection of Buildings, Conveyor galleries, trestles, in addition to this I was involved in erection & alignment of conveyor technological & travelling tripper. I am at Jamnagar for Reliance Petro-Chemical Project from 30.03.2015 to 29.02.2016. Here I am involved in Erection of structures(865MT) & equipment(494MT) of DTA- Slag Handling System. I am at Jamnagar for IOCL Petro-Chemical Project from 01.03.2016 to till date to look after Fabriction & Painting works of 5500MT Structural steel. Technical Skill: Software:Auto-CAD2004, NC/CNC Part Programming, Master CAM, DELCAM, PRO-E, CATIA V5R9, UG NX2, ANSYS 5.4. STRENGTHS: Ability to perform under stress. Grasping power. Sympathy for human and humanities. Self Confidence. PERSONAL PROFILE: Date of Birth : 23-06-1978. Sex : Male. Category : General. Marital status : Married. Languages known : English,Hindi,Oriya,Bengali. Address for corres. : HoldingNo.-378,Ward No.-15, Near Service StationGali,Chorda Chowk,JajpurRoad, Dist: Jajpur,Odisha-755019. Current CTC : 15lacs/Annum PLACE: PARADEEP, ODISHA. DATE: 17.10.16 (SUBHA KANTA BISWAL)