Report

Share

Recommended

Recommended

Reinforced arches have a wide range of applications. This paper discuss about use of fibre reinforced polymer (FRP) for strengthening of reinforced concrete arches. The experiment is conducted on shallow arches. Three arches are tested. One is used as a control arch while other two are strengthened using FRP strips in different patterns. Six non symmetric point loads are equally spaced along the arches. The arch is modelled as a polygon.Strengthening of RC Arches

Strengthening of RC ArchesFinal year Btech civil engineering student at viswajyothi college of engineering & technology

Retrofitting of an existing building is immensely essential for the deteriorated and damaged structure in Engineering and Medical fields. It refers to endowing the structure with a service level higher than that initially planned by modifying the structures, not necessarily damage area. Beam-column joints, being the lateral and vertical load transferring connections in reinforced concrete structures are particularly vulnerable to failures and hence the satisfactory performance of these joints is key to control the performance of connecting structural members during any event.

The project involves the study of the load carrying capacity of the beam-column joint after the application of the CFRP (Carbon Fiber Reinforced Polymer) and GFRP (Glass fibre Reinforced Polymer) sheets. Five beam-column joint models were cast out of which one model was the control specimen and others were cast for the purpose of the retrofitting. Four specimens were retrofitted by L-shape and straight configurations. The project focused on the effect of using the CFRP sheets and GFRP sheets for enhancing the strength and ductility of the beam-column joint. The wraps were provided to prevent the shear failure of the beam-column joint. The failure criteria including ultimate capacity, mode of failure, initial stiffness, ductility and developed ultimate strain in the reinforcing steel and respective sheet were considered and then compared.

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...Satyam Vijay Bhosale

More Related Content

What's hot

Reinforced arches have a wide range of applications. This paper discuss about use of fibre reinforced polymer (FRP) for strengthening of reinforced concrete arches. The experiment is conducted on shallow arches. Three arches are tested. One is used as a control arch while other two are strengthened using FRP strips in different patterns. Six non symmetric point loads are equally spaced along the arches. The arch is modelled as a polygon.Strengthening of RC Arches

Strengthening of RC ArchesFinal year Btech civil engineering student at viswajyothi college of engineering & technology

Retrofitting of an existing building is immensely essential for the deteriorated and damaged structure in Engineering and Medical fields. It refers to endowing the structure with a service level higher than that initially planned by modifying the structures, not necessarily damage area. Beam-column joints, being the lateral and vertical load transferring connections in reinforced concrete structures are particularly vulnerable to failures and hence the satisfactory performance of these joints is key to control the performance of connecting structural members during any event.

The project involves the study of the load carrying capacity of the beam-column joint after the application of the CFRP (Carbon Fiber Reinforced Polymer) and GFRP (Glass fibre Reinforced Polymer) sheets. Five beam-column joint models were cast out of which one model was the control specimen and others were cast for the purpose of the retrofitting. Four specimens were retrofitted by L-shape and straight configurations. The project focused on the effect of using the CFRP sheets and GFRP sheets for enhancing the strength and ductility of the beam-column joint. The wraps were provided to prevent the shear failure of the beam-column joint. The failure criteria including ultimate capacity, mode of failure, initial stiffness, ductility and developed ultimate strain in the reinforcing steel and respective sheet were considered and then compared.

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...Satyam Vijay Bhosale

What's hot (20)

Steel fibers for reinforced concrete kasturi metal

Steel fibers for reinforced concrete kasturi metal

Advantages of steel fibre reinforced concrete in industrial floors

Advantages of steel fibre reinforced concrete in industrial floors

Experimental study on Torsion behavior of Flange beam with GFRP

Experimental study on Torsion behavior of Flange beam with GFRP

Fatigue behaviour of reinforced concrete beams with corroded

Fatigue behaviour of reinforced concrete beams with corroded

Flexural behaviour of reinforced cement concrete beam wrapped with gfrp sheet

Flexural behaviour of reinforced cement concrete beam wrapped with gfrp sheet

Modeling and Analysis of Retrofitted Exterior RC Beam Column connection

Modeling and Analysis of Retrofitted Exterior RC Beam Column connection

IRJET - Flexural Behaviour of Reinforced Concrete Beams Strengthened with BFR...

IRJET - Flexural Behaviour of Reinforced Concrete Beams Strengthened with BFR...

IRJET- Study on Flexural Strengthening of RC Beam with Steel Fibres in Ferroc...

IRJET- Study on Flexural Strengthening of RC Beam with Steel Fibres in Ferroc...

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...

Retrofitting of Beam-Column Joint using Carbon Fibre Reinforced Polymer and G...

Viewers also liked

Viewers also liked (18)

Prospecting sellers property information-worksheet

Prospecting sellers property information-worksheet

dermatomiositis-Servicio de Clinica Medica-Sanatorio Parque

dermatomiositis-Servicio de Clinica Medica-Sanatorio Parque

Similar to Fiberglass Box Poster

Cable Joint Instruction - Zero Halogen Fire Resistant Power Cable Joint (BS7846)Cable Joint Instruction - Zero Halogen Fire Resistant Power Cable Joint (BS7846)

Cable Joint Instruction - Zero Halogen Fire Resistant Power Cable Joint (BS7846)Thorne & Derrick International

Presented at the XXIV Nordic Concrete Research Symposium in Stockholm, August 17-19, 2022.D1 (A3) Viktor Peterson - Evaluation of dynamically tested concrete beams rei...

D1 (A3) Viktor Peterson - Evaluation of dynamically tested concrete beams rei...Svenska Betongföreningen

Similar to Fiberglass Box Poster (20)

Numerical Investigations on Blast Protection System with Metallic Tube Core S...

Numerical Investigations on Blast Protection System with Metallic Tube Core S...

IRJET- A Study on Post Tensioned Beams Strengthened with AFRP Fabric

IRJET- A Study on Post Tensioned Beams Strengthened with AFRP Fabric

IRJET- Assessment of Noise in Industrial and Commercial Zones of an Urban Set...

IRJET- Assessment of Noise in Industrial and Commercial Zones of an Urban Set...

IRJET- Study of Cold-Formed Steel Flexural Member Under Monotonic and Reverse...

IRJET- Study of Cold-Formed Steel Flexural Member Under Monotonic and Reverse...

Study on the Compression Behaviour of Self-Compacting Concrete Columns using ...

Study on the Compression Behaviour of Self-Compacting Concrete Columns using ...

Building structure (project 1:Fettuccine Truss Bridge)

Building structure (project 1:Fettuccine Truss Bridge)

Seismic response of steel beams coupling concrete walls

Seismic response of steel beams coupling concrete walls

Cable Joint Instruction - Zero Halogen Fire Resistant Power Cable Joint (BS7846)

Cable Joint Instruction - Zero Halogen Fire Resistant Power Cable Joint (BS7846)

Experimental Investigation of Reinforced Concrete Beam with Opening for Combi...

Experimental Investigation of Reinforced Concrete Beam with Opening for Combi...

Design and Analysis of Acrylic Paneled Rectangular Towing Tank

Design and Analysis of Acrylic Paneled Rectangular Towing Tank

D1 (A3) Viktor Peterson - Evaluation of dynamically tested concrete beams rei...

D1 (A3) Viktor Peterson - Evaluation of dynamically tested concrete beams rei...

Fiberglass Box Poster

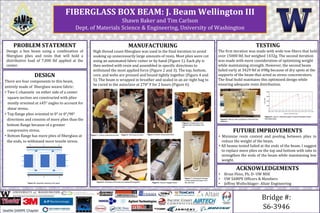

- 1. FIBERGLASS BOX BEAM: J. Beam Wellington III Shawn Baker and Tim Carlson Dept. of Materials Science & Engineering, University of Washington Bridge #: S6-3946 PROBLEM STATEMENT Design a box beam using a combination of fiberglass plies and resin that will hold a distributive load of 7,000 lbf applied at the center. MANUFACTURING High thread count fiberglass was used in the final iteration to avoid soaking up unnecessarily large amounts of resin. Most plies were cut using an automated fabric cutter or by hand (Figure 1). Each ply is then wetted with resin and assembled in specific directions to withstand the most applied force (Figure 2 and 3). The top, bottom, core, and webs are pressed and bound tightly together (Figure 4 and 5). The beam is wrapped in breather and sealed in an air-tight bag to be cured in the autoclave at 270ᵒ F for 2 hours (Figure 6). TESTING The first iteration was made with wide tow fibers that held over 15000 lbf, but weighed 1432g. The second iteration was made with more consideration of optimizing weight while maintaining strength. However, the second beam failed early at 3429 lbf at 698g because of dry spots at the supports of the beam that acted as stress concentrators. The final build maintains this optimized design while ensuring adequate resin distribution. DESIGN There are four components to this beam, entirely made of fiberglass weave fabric: • Two C-channels on either side of a center square section are constructed with plies mostly oriented at ±45° angles to account for shear stress. • Top flange plies oriented in 0° or 0°/90° directions and consists of more plies than the bottom flange because of a greater compressive stress. • Bottom flange has more plies of fiberglass at the ends, to withstand more tensile stress. FUTURE IMPROVEMENTS • Minimize resin content and pooling between plies to reduce the weight of the beam. • All beams tested failed at the ends of the beam. I suggest to replace more plies on the top and bottom with tabs to strengthen the ends of the beam while maintaining low weight. ACKNOWLEDGEMENTS • Brian Flinn, Ph. D- UW MSE • UW SAMPE Officers & Members • Jeffrey Wollschlager- Altair EngineeringFigure 6: Vacuum bagged beam Figure 8: Side by side comparison of the first two iterations. Figure 1: Cutting unidirectional plies Figure 2: Wet layup process Figure 3: Bottom being assembled Figure 4: Pressing the core together with the bottom and top Figure 5: All pieces of the beam are assembled together Figure 7: Using liquid nitrogen to help release the beam from the core tool Figure 9: Load vs. extension graph of second iteration beam that failed early Figure 10: Assembly drawing of the beam