More Related Content

Similar to CAMANCHE Bevelers RISK ASSESSMENT Complete

Similar to CAMANCHE Bevelers RISK ASSESSMENT Complete (20)

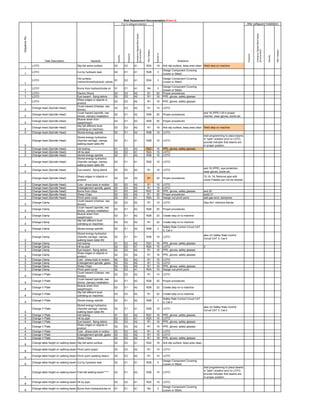

CAMANCHE Bevelers RISK ASSESSMENT Complete

- 1. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

1

LOTO Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean Weld step on machine

1

LOTO Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

1

LOTO

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 3

Design Component Covering

(Lexan or Steel)

1

LOTO Burns from hydraulic/lube oil S1 E1 A1 R4 3

Design Component Covering

(Lexan or Steel)

1 LOTO Electric Shock S2 E2 A2 R1 20 Proper procedures

1 LOTO Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

1

LOTO

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

2

Change head (Spindle Head)

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

2

Change head (Spindle Head)

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 20 Proper procedures

and 16 (PPE) Lift in proper

manner, wear gloves, boots etc.

2

Change head (Spindle Head)

Muscle strain from

weight/reach

S2 E1 A2 R2B 20 Proper procedures

2

Change head (Spindle Head)

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 18 Anti slip surface, keep area clean Weld step on machine

2 Change head (Spindle Head) Stored energy spindle S2 E1 A2 R2B 15 LOTO

2

Change head (Spindle Head)

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

2 Change head (Spindle Head) Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

2 Change head (Spindle Head) Hit by pipe S2 E2 A1 R2A 15 LOTO

2 Change head (Spindle Head) Stored energy spindle S2 E1 A2 R2B 15 LOTO

2

Change head (Spindle Head)

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

2

Change head (Spindle Head) Eye hazard - flying debris S2 E2 A2 R1 15 LOTO

and 16 (PPE) ,eye protection,

wear gloves, boots etc.

2

Change head (Spindle Head)

Sharp edges or objects or

product

S2 E2 A2 R1 20 Proper procedures

15,16, 18, Remove pipe with

crane if tables can not be cleared

2 Change head (Spindle Head) Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

2 Change head (Spindle Head) Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

2 Change head (Spindle Head) Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses and 20

2 Change head (Spindle Head) Sharp Chips S2 E2 A2 R1 20 Proper procedures andd 21

2 Change head (Spindle Head) Pinch point cover S2 E2 A1 R2A 10 Design out pinch point add gas strut, dampener

3

Change Clamp

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO Also No1 Interlock Barrier

3

Change Clamp

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 20 Proper procedures

3

Change Clamp

Muscle strain from

weight/reach

S2 E1 A2 R2B 22 Create step on to machine

3

Change Clamp

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

3

Change Clamp Stored energy spindle S2 E1 A2 R2B 2

Safety Rate Control Circuit CAT

3, Cat 4

3

Change Clamp

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

3 Change Clamp Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

3 Change Clamp Hit by pipe S2 E2 A1 R2A 15 LOTO 2

3 Change Clamp Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

3

Change Clamp

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

3 Change Clamp Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

3 Change Clamp Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

3 Change Clamp Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

3 Change Clamp Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

4

Change V Plate

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

4

Change V Plate

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 20 Proper procedures

4

Change V Plate

Muscle strain from

weight/reach

S2 E1 A2 R2B 22 Create step on to machine

4

Change V Plate

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

4

Change V Plate Stored energy spindle S2 E1 A2 R2B 2

Safety Rate Control Circuit CAT

3, Cat 4

4

Change V Plate

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

4 Change V Plate Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

4 Change V Plate Hit by pipe S2 E2 A1 R2A 15 LOTO

4 Change V Plate Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

4

Change V Plate

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

4 Change V Plate Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

4 Change V Plate Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

4 Change V Plate Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

5

Change table height on walking beam Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

5

Change table height on walking beam Pinch point (pipe) S2 E2 A2 R1 15 LOTO

5

Change table height on walking beam Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

5

Change table height on walking beam Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

5

Change table height on walking beam Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

5

Change table height on walking beam Hit by pipe S2 E2 A1 R2A 15 LOTO

5

Change table height on walking beam Burns from hydraulic/lube oil S1 E1 A1 R4 3

Design Component Covering

(Lexan or Steel)

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

- 2. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

5

Change table height on walking beam Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

6

Change tooling

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 2

Safety Rate Control Circuit CAT

3, Cat 4

and 1

6

Change tooling

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 2

Safety Rate Control Circuit CAT

3, Cat 4

Stop fair ending when gate opens

Install gated area on upstreem

side.

6

Change tooling

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 15 LOTO or 2 with controlled access

6

Change tooling Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean Add steps to access tooling

6

Change tooling

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 18 Anti slip surface, keep area clean Add steps to access tooling

6 Change tooling Pinch point (pipe) S2 E2 A2 R1 15 LOTO or 2 with controlled access

6 Change tooling Stored energy spindle S2 E1 A2 R2B 15 LOTO or 2 with controlled access

6

Change tooling

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO or 2 with controlled access

6 Change tooling Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

6 Change tooling Hit by pipe S2 E2 A1 R2A 15 LOTO

6 Change tooling Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

6

Change tooling

Sharp edges or objects or

product

S2 E2 A2 R1 15 LOTO and 16

6 Change tooling Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

6 Change tooling Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

6 Change tooling Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses and 21

6 Change tooling Sharp Chips S2 E2 A2 R1 21 Chip brush, clear chips and 16

6 Change tooling Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

7

Adjust tooling (shim at times)

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

7

Adjust tooling (shim at times)

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO 20

7

Adjust tooling (shim at times) Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

7

Adjust tooling (shim at times)

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

7 Adjust tooling (shim at times) Pinch point (pipe) S2 E2 A2 R1 15 LOTO

7

Adjust tooling (shim at times) Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

7

Adjust tooling (shim at times)

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

7 Adjust tooling (shim at times) Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

7 Adjust tooling (shim at times) Hit by pipe S2 E2 A1 R2A 15 LOTO

7 Adjust tooling (shim at times) Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

7

Adjust tooling (shim at times)

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

7

Adjust tooling (shim at times) Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

7

Adjust tooling (shim at times) Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

7 Adjust tooling (shim at times) Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

7 Adjust tooling (shim at times) Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

7 Adjust tooling (shim at times) Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

8

Change gears ratio

Muscle strain from

weight/reach

S2 E1 A2 R2B 20 Proper procedures

8

Change gears ratio Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

8

Change gears ratio Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

8

Change gears ratio

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

8 Change gears ratio Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

8

Change gears ratio

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

9

Adjust clamps (shim at times)

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

9

Adjust clamps (shim at times)

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

9

Adjust clamps (shim at times) Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

9

Adjust clamps (shim at times)

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

9 Adjust clamps (shim at times) Pinch point (pipe) S2 E2 A2 R1 10 Design out pinch point

9

Adjust clamps (shim at times) Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

9

Adjust clamps (shim at times)

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

9 Adjust clamps (shim at times) Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

9 Adjust clamps (shim at times) Hit by pipe S2 E2 A1 R2A 15 LOTO

9 Adjust clamps (shim at times) Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

9

Adjust clamps (shim at times)

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

9

Adjust clamps (shim at times) Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

9 Adjust clamps (shim at times) Entanglement spindle, gears S2 E2 A2 R1 15 LOTO 2

9 Adjust clamps (shim at times) Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

9 Adjust clamps (shim at times) Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

9 Adjust clamps (shim at times) Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

11

Adjust limit switches machine travel Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

11

Adjust limit switches machine travel

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 20 Proper procedures

11 Adjust limit switches machine travel Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

11

Adjust limit switches machine travel

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

- 3. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

11 Adjust limit switches machine travel Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

13 Check height of table Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

14 Manually clamp Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

15 Cycle machine forward to bevel pipe Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

15

Cycle machine forward to bevel pipe

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

15

Cycle machine forward to bevel pipe Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

15 Cycle machine forward to bevel pipe Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

15 Cycle machine forward to bevel pipe Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

16

check bevel in machine

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO add 1 Interlocking Barriers

16

check bevel in machine

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

16 check bevel in machine Pinch point (pipe) S2 E2 A2 R1 15 LOTO

16

check bevel in machine Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

16

check bevel in machine

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

16 check bevel in machine Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

16 check bevel in machine Hit by pipe S2 E2 A1 R2A 15 LOTO

16 check bevel in machine Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

16

check bevel in machine

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

16 check bevel in machine Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

16

check bevel in machine Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

16 check bevel in machine Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

16 check bevel in machine Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

16 check bevel in machine Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

16 #N/A #N/A #N/A #N/A #N/A

18

walk pipe out

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 1 Interlocked Barrier new tech?

18

walk pipe out Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

18 walk pipe out Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

18 walk pipe out Pinch point (walking beam) S2 E2 A2 R1 1 Interlocked Barrier

18 walk pipe out Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

18 walk pipe out Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

18

walk pipe out

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

18 walk pipe out Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

18 walk pipe out Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

20

Remove burr with file

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 1 Interlocked Barrier new tech?

20 Remove burr with file Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

20 Remove burr with file Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

20 Remove burr with file Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

20

Remove burr with file

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

20 Remove burr with file Cuts - sharp tools in motion S2 E2 A2 R1 16 PPE, gloves, safety glasses

20 Remove burr with file Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

20 Remove burr with file Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

20 Remove burr with file Puncture Wound File Tang S2 E2 A1 R2A 19 Proper tools

21

Remove chips with brush (possibly

long chips around pipe)

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 1 Interlocked Barrier

21

Remove chips with brush (possibly

long chips around pipe)

Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

21

Remove chips with brush (possibly

long chips around pipe)

Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

21

Remove chips with brush (possibly

long chips around pipe)

Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

21

Remove chips with brush (possibly

long chips around pipe)

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

21

Remove chips with brush (possibly

long chips around pipe)

Cuts - sharp tools in motion S2 E2 A2 R1 1 Interlocked Barrier

21

Remove chips with brush (possibly

long chips around pipe)

Entanglement spindle, gears S2 E2 A2 R1 1 Interlocked Barrier

21

Remove chips with brush (possibly

long chips around pipe)

Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

21

Remove chips with brush (possibly

long chips around pipe)

Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

22

Clean around floor (chips)

Muscle strain from

weight/reach

S2 E1 A2 R2B 15 LOTO

22

Clean around floor (chips) Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

22 Clean around floor (chips) Pinch point (pipe) S2 E2 A2 R1 10 Design out pinch point

22 Clean around floor (chips) Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

22

Clean around floor (chips) Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

22 Clean around floor (chips) Hit by pipe S2 E2 A1 R2A 15 LOTO

22 Clean around floor (chips) Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

22

Clean around floor (chips)

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

22

Clean around floor (chips) Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

22 Clean around floor (chips) Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

22 Clean around floor (chips) Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

24

Rotate spindle 120deg during setup

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

24

Rotate spindle 120deg during setup

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

24

Rotate spindle 120deg during setup

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools control reliable jog switch

24

Rotate spindle 120deg during setup Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

24

Rotate spindle 120deg during setup

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

24 Rotate spindle 120deg during setup Pinch point (pipe) S2 E2 A2 R1 15 LOTO

- 4. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

24

Rotate spindle 120deg during setup Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

24

Rotate spindle 120deg during setup

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

24 Rotate spindle 120deg during setup Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

24 Rotate spindle 120deg during setup Hit by pipe S2 E2 A1 R2A 15 LOTO

24 Rotate spindle 120deg during setup Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

24

Rotate spindle 120deg during setup

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

24

Rotate spindle 120deg during setup Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

24

Rotate spindle 120deg during setup Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

24 Rotate spindle 120deg during setup Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

24 Rotate spindle 120deg during setup Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

24 Rotate spindle 120deg during setup Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

25

Remove chips from tool holders

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

25

Remove chips from tool holders

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

25

Remove chips from tool holders Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

25

Remove chips from tool holders

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

25 Remove chips from tool holders Pinch point (pipe) S2 E2 A2 R1 15 LOTO

25

Remove chips from tool holders Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

25

Remove chips from tool holders

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

25 Remove chips from tool holders Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

25 Remove chips from tool holders Hit by pipe S2 E2 A1 R2A 15 LOTO

25 Remove chips from tool holders Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

25

Remove chips from tool holders

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

25 Remove chips from tool holders Cuts - sharp tools in motion S2 E2 A2 R1 16 PPE, gloves, safety glasses

25

Remove chips from tool holders Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

25 Remove chips from tool holders Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

25 Remove chips from tool holders Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

25 Remove chips from tool holders Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

26

Remove chips from spindle

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

26

Remove chips from spindle

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

26

Remove chips from spindle Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

26

Remove chips from spindle

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

26 Remove chips from spindle Pinch point (pipe) S2 E2 A2 R1 15 LOTO

26

Remove chips from spindle Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

26

Remove chips from spindle

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

26 Remove chips from spindle Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

26 Remove chips from spindle Hit by pipe S2 E2 A1 R2A 15 LOTO

26 Remove chips from spindle Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

26

Remove chips from spindle

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

26

Remove chips from spindle Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

26

Remove chips from spindle Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

26 Remove chips from spindle Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

26 Remove chips from spindle Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

26 Remove chips from spindle Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

27 Paint bad bevels yellow Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

27 Paint bad bevels yellow Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

27 Paint bad bevels yellow Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

27

Paint bad bevels yellow

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

28

Drop in dump bay (manual operation

through control system)

Hit by pipe S2 E2 A1 R2A 20 Proper procedures

29

Roll/straighten crooked pipe

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

29

Roll/straighten crooked pipe

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

29

Roll/straighten crooked pipe Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

29 Roll/straighten crooked pipe Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

29 Roll/straighten crooked pipe Hit by pipe S2 E2 A1 R2A 15 LOTO

29 Roll/straighten crooked pipe Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

29

Roll/straighten crooked pipe

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

29 Roll/straighten crooked pipe Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

29 Roll/straighten crooked pipe Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

30

Check land, bevel angle and ID

chamfer for burr

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 1 Interlocked Barrier

30

Check land, bevel angle and ID

chamfer for burr

Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

30

Check land, bevel angle and ID

chamfer for burr

Pinch point (pipe) S2 E2 A2 R1 1 Interlocked Barrier

30

Check land, bevel angle and ID

chamfer for burr

Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

30

Check land, bevel angle and ID

chamfer for burr

Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

30

Check land, bevel angle and ID

chamfer for burr

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

- 5. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

30

Check land, bevel angle and ID

chamfer for burr

Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

30

Check land, bevel angle and ID

chamfer for burr

Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

31

View clamp pressure during setup Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

31

View clamp pressure during setup

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses and (3) design Component Cover

31 View clamp pressure during setup Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

31 View clamp pressure during setup Pinch point rear of machine 0 0 0 20 Proper procedures

32

Unplug chip conveyor

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

32

Unplug chip conveyor

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

32

Unplug chip conveyor

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

32

Unplug chip conveyor Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

32

Unplug chip conveyor

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

32 Unplug chip conveyor Pinch point (pipe) S2 E2 A2 R1 20 Proper procedures

32

Unplug chip conveyor Stored energy spindle S2 E1 A2 R2B 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

32

Unplug chip conveyor

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

32 Unplug chip conveyor Hit by pipe S2 E2 A1 R2A 15 LOTO

32 Unplug chip conveyor Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

32

Unplug chip conveyor

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

32 Unplug chip conveyor Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

32 Unplug chip conveyor Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

32 Unplug chip conveyor Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

32 Unplug chip conveyor Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

32 Unplug chip conveyor Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

32 Unplug chip conveyor Entanglement Chip Conveyor S2 E2 A1 R2A 19 Proper tools

33 Adjust RPM (spindle dial) Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

34 System startup (controls) Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

35

Lube pump replacement Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

36

Broken clamp bolt removal

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

36

Broken clamp bolt removal

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

36

Broken clamp bolt removal

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 15 LOTO

36

Broken clamp bolt removal Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

36

Broken clamp bolt removal

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

36 Broken clamp bolt removal Pinch point (pipe) S2 E2 A2 R1 15 LOTO

36

Broken clamp bolt removal

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

36 Broken clamp bolt removal Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

36 Broken clamp bolt removal Hit by pipe S2 E2 A1 R2A 15 LOTO

36 Broken clamp bolt removal Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

36

Broken clamp bolt removal

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

36

Broken clamp bolt removal Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

36

Broken clamp bolt removal Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

also (2) Safety Rate Control

Circuit CAT 3, Cat 4

36 Broken clamp bolt removal Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

36 Broken clamp bolt removal Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

36 Broken clamp bolt removal Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

38

Walking beam coupling replacement

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

38

Walking beam coupling replacement

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

38

Walking beam coupling replacement Pinch point (pipe) S2 E2 A2 R1 15 LOTO

38

Walking beam coupling replacement Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

38

Walking beam coupling replacement

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

38

Walking beam coupling replacement Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

38

Walking beam coupling replacement Hit by pipe S2 E2 A1 R2A 15 LOTO

38

Walking beam coupling replacement

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 15 LOTO

38

Walking beam coupling replacement Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

38

Walking beam coupling replacement Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

40 Alignment roll drive reset Electric Shock S2 E2 A2 R1 15 LOTO

40 Alignment roll drive reset Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

41

Install/replace oil pads

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

41

Install/replace oil pads

Muscle strain from

weight/reach

S2 E1 A2 R2B 15 LOTO

41

Install/replace oil pads Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

41 Install/replace oil pads Pinch point (pipe) S2 E2 A2 R1 15 LOTO

41 Install/replace oil pads Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

- 6. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

41

Install/replace oil pads Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

41 Install/replace oil pads Hit by pipe S2 E2 A1 R2A 15 LOTO

41 Install/replace oil pads Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

41

Install/replace oil pads

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

41 Install/replace oil pads Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

41 Install/replace oil pads Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

41 Install/replace oil pads Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

42

Oil check/Add Oil/Way Lube System Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

42

Oil check/Add Oil/Way Lube System Pinch point rear of machine 0 0 0 15 LOTO

44

Oil change alignment rolls

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

44

Oil change alignment rolls

Muscle strain from

weight/reach

S2 E1 A2 R2B 15 LOTO

44 Oil change alignment rolls Pinch point (pipe) S2 E2 A2 R1 15 LOTO

44 Oil change alignment rolls Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

44

Oil change alignment rolls

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

44

Oil change alignment rolls Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

44 Oil change alignment rolls Hit by pipe S2 E2 A1 R2A 15 LOTO

44

Oil change alignment rolls

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

44 Oil change alignment rolls Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

44 Oil change alignment rolls Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

45

Oil change walking beam gear boxes

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

45

Oil change walking beam gear boxes

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

45

Oil change walking beam gear boxes Pinch point (pipe) S2 E2 A2 R1 15 LOTO

45

Oil change walking beam gear boxes Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

45

Oil change walking beam gear boxes

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

45

Oil change walking beam gear boxes Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

45

Oil change walking beam gear boxes Hit by pipe S2 E2 A1 R2A 15 LOTO

45

Oil change walking beam gear boxes

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

45

Oil change walking beam gear boxes Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

45

Oil change walking beam gear boxes Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

45 #N/A #N/A #N/A #N/A #N/A

46

Oil check walking beam gear boxes

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

46

Oil check walking beam gear boxes

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

46 Oil check walking beam gear boxes Pinch point (pipe) S2 E2 A2 R1 15 LOTO

46 Oil check walking beam gear boxes Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

46

Oil check walking beam gear boxes

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

46 Oil check walking beam gear boxes Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

46 Oil check walking beam gear boxes Hit by pipe S2 E2 A1 R2A 15 LOTO

46

Oil check walking beam gear boxes

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

46 Oil check walking beam gear boxes Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

46 Oil check walking beam gear boxes Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

46 #N/A #N/A #N/A #N/A #N/A

47

Lube material handling system

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

47

Lube material handling system

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

47 Lube material handling system Pinch point (pipe) S2 E2 A2 R1 15 LOTO

47 Lube material handling system Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

47

Lube material handling system

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

47

Lube material handling system Free fall walking beam***** S2 E1 A2 R2B 15 LOTO

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

47 Lube material handling system Hit by pipe S2 E2 A1 R2A 15 LOTO

47

Lube material handling system

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

47 Lube material handling system Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

47 Lube material handling system Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

47 #N/A #N/A #N/A #N/A #N/A

48

Pipe removal from reject bin

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 20 Proper procedures

48

Pipe removal from reject bin

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

48

Pipe removal from reject bin Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

48 Pipe removal from reject bin Pinch point (pipe) S2 E2 A2 R1 20 Proper procedures

- 7. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

48

Pipe removal from reject bin

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 20 Proper procedures

48

Pipe removal from reject bin Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

48 Pipe removal from reject bin Hit by pipe S2 E2 A1 R2A 1 Interlocked Barrier

48 Pipe removal from reject bin Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

48

Pipe removal from reject bin

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

48 Pipe removal from reject bin Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

49

Accumulator replacement

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

49

Accumulator replacement Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

49

Accumulator replacement

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

49 Accumulator replacement Cut by hydraulic leak S2 E1 A1 R2B 15 LOTO

49

Accumulator replacement

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

49 Accumulator replacement Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

49 Accumulator replacement Electric Shock S2 E2 A2 R1 20 Proper procedures

49 Accumulator replacement Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

49 Accumulator replacement Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

49 #N/A #N/A #N/A #N/A #N/A

50

Hydro valve replacement

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

50

Hydro valve replacement Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

50

Hydro valve replacement

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

50 Hydro valve replacement Cut by hydraulic leak S2 E1 A1 R2B 15 LOTO

50

Hydro valve replacement

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

50 Hydro valve replacement Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

50 Hydro valve replacement Electric Shock S2 E2 A2 R1 15 LOTO

50 Hydro valve replacement Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

50 Hydro valve replacement Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

51

Heat exchanger

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

51

Heat exchanger Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

51

Heat exchanger

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

51 Heat exchanger Cut by hydraulic leak S2 E1 A1 R2B 15 LOTO

51

Heat exchanger

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

51 Heat exchanger Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

51 Heat exchanger Electric Shock S2 E2 A2 R1 15 LOTO

51 Heat exchanger Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

51 Heat exchanger Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

52

Pump replacement hydro

Muscle strain from

weight/reach

S2 E1 A2 R2B 19 Proper tools

52

Pump replacement hydro Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

52

Pump replacement hydro

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

52 Pump replacement hydro Cut by hydraulic leak S2 E1 A1 R2B 15 LOTO

52

Pump replacement hydro

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

52 Pump replacement hydro Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

52 Pump replacement hydro Electric Shock S2 E2 A2 R1 15 LOTO

52 Pump replacement hydro Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

52 Pump replacement hydro Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

54

General maintenance

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

54

General maintenance

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

54

General maintenance

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 15 LOTO

54

General maintenance

Muscle strain from

weight/reach

S2 E1 A2 R2B 20 Proper procedures 19

54

General maintenance Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

54

General maintenance

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

54 General maintenance Pinch point (pipe) S2 E2 A2 R1 15 LOTO

54 General maintenance Pinch point (walking beam) S2 E2 A2 R1 20 Proper procedures

54 General maintenance Stored energy spindle S2 E1 A2 R2B 15 LOTO

54

General maintenance

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

54 General maintenance Cut by hydraulic leak S2 E1 A1 R2B 15 LOTO

54 General maintenance Hot tooling S1 E2 A2 R2C 15 LOTO

54

General maintenance

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

54

General maintenance Free fall walking beam***** S2 E1 A2 R2B 20 Proper procedures

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

54 General maintenance Hit by pipe S2 E2 A1 R2A 15 LOTO

54

General maintenance

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

- 8. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

54 General maintenance Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

54 General maintenance Electric Shock S2 E2 A2 R1 15 LOTO

54 General maintenance Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

54

General maintenance

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

54 General maintenance Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

54 General maintenance Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

54 General maintenance Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

54 General maintenance Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

54 General maintenance Pinch point rear of machine 0 0 0 15 LOTO

54 General maintenance Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

54 General maintenance Puncture Wound File Tang S2 E2 A1 R2A 19 Proper tools

54 General maintenance Entanglement Chip Conveyor S2 E2 A1 R2A 16 PPE, gloves, safety glasses

54 General maintenance Arc Flash S2 E1 A2 R2B 15 LOTO

56

Recover pipe that has fallen through

walking beam

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

56

Recover pipe that has fallen through

walking beam

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 15 LOTO

56

Recover pipe that has fallen through

walking beam

Muscle strain from

weight/reach

S2 E1 A2 R2B 20 Proper procedures

56

Recover pipe that has fallen through

walking beam

Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

56

Recover pipe that has fallen through

walking beam

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

56

Recover pipe that has fallen through

walking beam

Pinch point (pipe) S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Pinch point (walking beam) S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Stored energy spindle S2 E1 A2 R2B 15 LOTO

56

Recover pipe that has fallen through

walking beam

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

56

Recover pipe that has fallen through

walking beam

Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

56

Recover pipe that has fallen through

walking beam

Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

56

Recover pipe that has fallen through

walking beam

Free fall walking beam***** S2 E1 A2 R2B 20 Proper procedures

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

56

Recover pipe that has fallen through

walking beam

Hit by pipe S2 E2 A1 R2A 15 LOTO

56

Recover pipe that has fallen through

walking beam

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Electric Shock S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

56

Recover pipe that has fallen through

walking beam

Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

56

Recover pipe that has fallen through

walking beam

Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

56

Recover pipe that has fallen through

walking beam

Entanglement Chip Conveyor S2 E2 A1 R2A 15 LOTO

57

Change/Adjust sensors

Crush hazard (Clamps, vee

blocks)

S2 E2 A2 R1 15 LOTO

57

Change/Adjust sensors

Crush hazard (pipe exit, fair

end)

S2 E2 A1 R2A 15 LOTO

57

Change/Adjust sensors

Crush hazard (spindle, vee

blocks, clamps) installation

S2 E1 A2 R2B 15 LOTO

57

Change/Adjust sensors

Muscle strain from

weight/reach

S2 E1 A2 R2B 20 Proper procedures

57

Change/Adjust sensors Slip fall same surface S2 E2 A1 R2A 18 Anti slip surface, keep area clean

57

Change/Adjust sensors

Slip fall different level

(climbing on machine)

S2 E2 A2 R1 22 Create step on to machine

57 Change/Adjust sensors Pinch point (pipe) S2 E2 A2 R1 15 LOTO

57 Change/Adjust sensors Pinch point (walking beam) S2 E2 A2 R1 20 Proper procedures

57 Change/Adjust sensors Stored energy spindle S2 E1 A2 R2B 15 LOTO

57

Change/Adjust sensors

Stored energy hydraulics

(Spindle carriage, clamps,

walking beam table lift)

S2 E1 A1 R2B 15 LOTO

57

Change/Adjust sensors Cut by hydraulic leak S2 E1 A1 R2B 3

Design Component Covering

(Lexan or Steel)

57 Change/Adjust sensors Hot tooling S1 E2 A2 R2C 16 PPE, gloves, safety glasses

57

Change/Adjust sensors

Stored pneumatic energy

(clutch, clamps)

S1 E1 A1 R4 15 LOTO

57

Change/Adjust sensors Free fall walking beam***** S2 E1 A2 R2B 20 Proper procedures

Add programming to place beams

in "park" position prior to LOTO,

provide indicator that beams are

in proper position.

57 Change/Adjust sensors Hit by pipe S2 E2 A1 R2A 15 LOTO

57

Change/Adjust sensors

Hot surface-

motors/drives/hydraulic valves

S1 E2 A1 R3A 16 PPE, gloves, safety glasses

- 9. SequenceNo.

Task Description Hazards

Severity

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

RiskCategory

Solution#

Solutions

Exposure

Avoidance(Speed)BlindSpots)

(Environment)

Severity

RiskCategory

Prior to safeguard selection After safeguard Installation

Risk Assessment Documentation (Form 3)

57 Change/Adjust sensors Burns from hydraulic/lube oil S1 E1 A1 R4 16 PPE, gloves, safety glasses

57 Change/Adjust sensors Electric Shock S2 E2 A2 R1 15 LOTO

57 Change/Adjust sensors Eye hazard - flying debris S2 E2 A2 R1 16 PPE, gloves, safety glasses

57

Change/Adjust sensors

Sharp edges or objects or

product

S2 E2 A2 R1 16 PPE, gloves, safety glasses

57 Change/Adjust sensors Cuts - sharp tools in motion S2 E2 A2 R1 15 LOTO

57 Change/Adjust sensors Entanglement spindle, gears S2 E2 A2 R1 15 LOTO

57 Change/Adjust sensors Burns from chips S1 E2 A2 R2C 16 PPE, gloves, safety glasses

57 Change/Adjust sensors Sharp Chips S2 E2 A2 R1 16 PPE, gloves, safety glasses

57 Change/Adjust sensors Pinch point rear of machine 0 0 0 15 LOTO

57 Change/Adjust sensors Pinch point cover S2 E2 A1 R2A 10 Design out pinch point

57 Change/Adjust sensors Entanglement Chip Conveyor S2 E2 A1 R2A 19 Proper tools