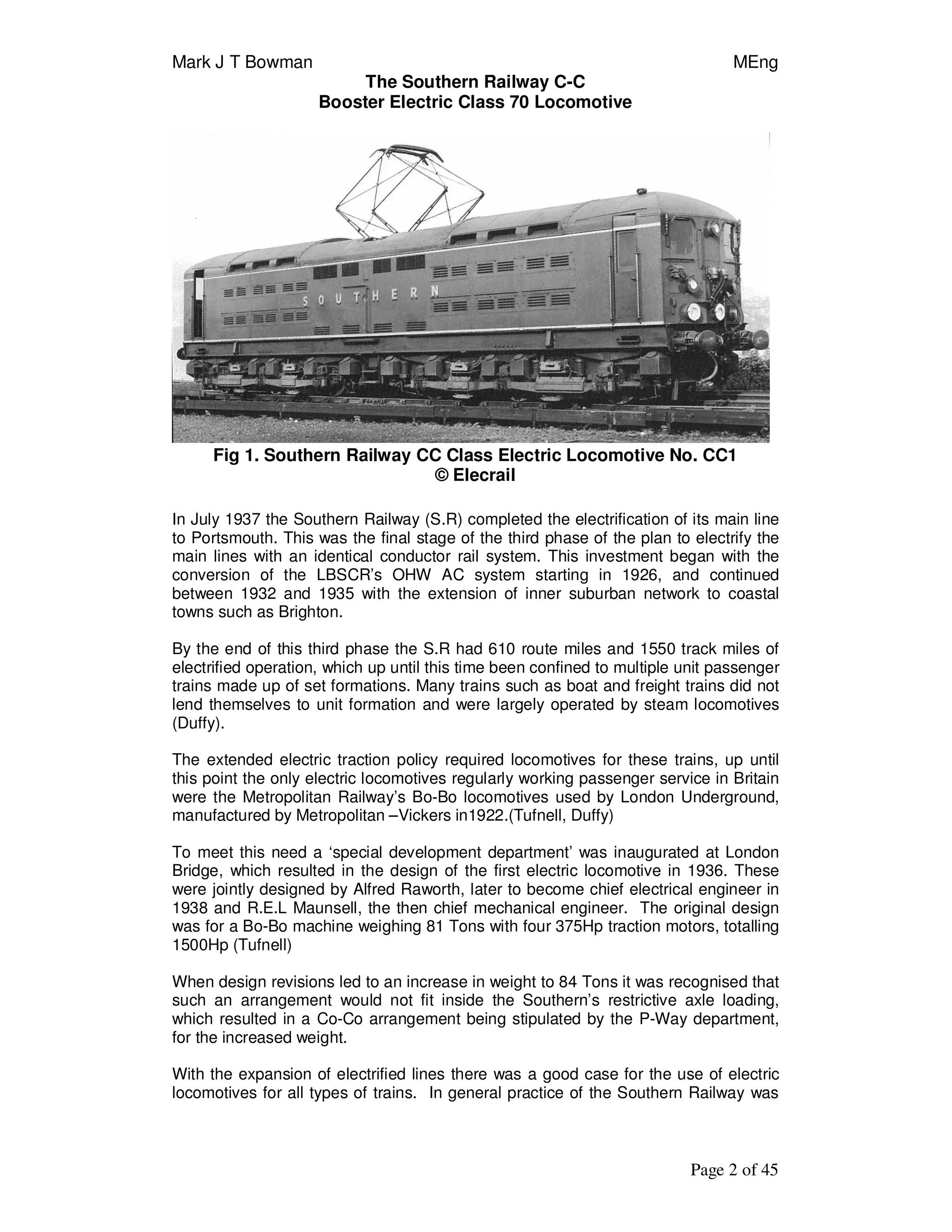

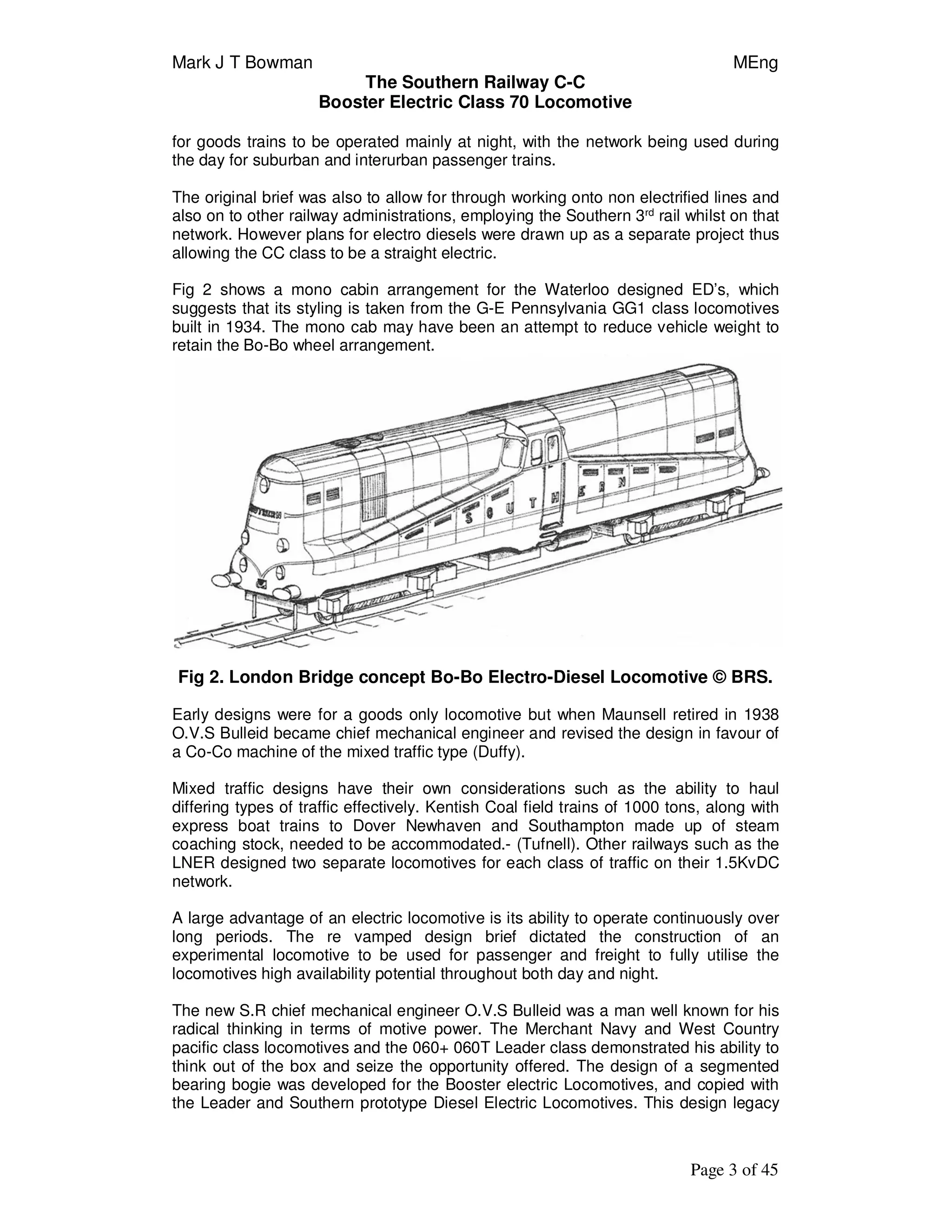

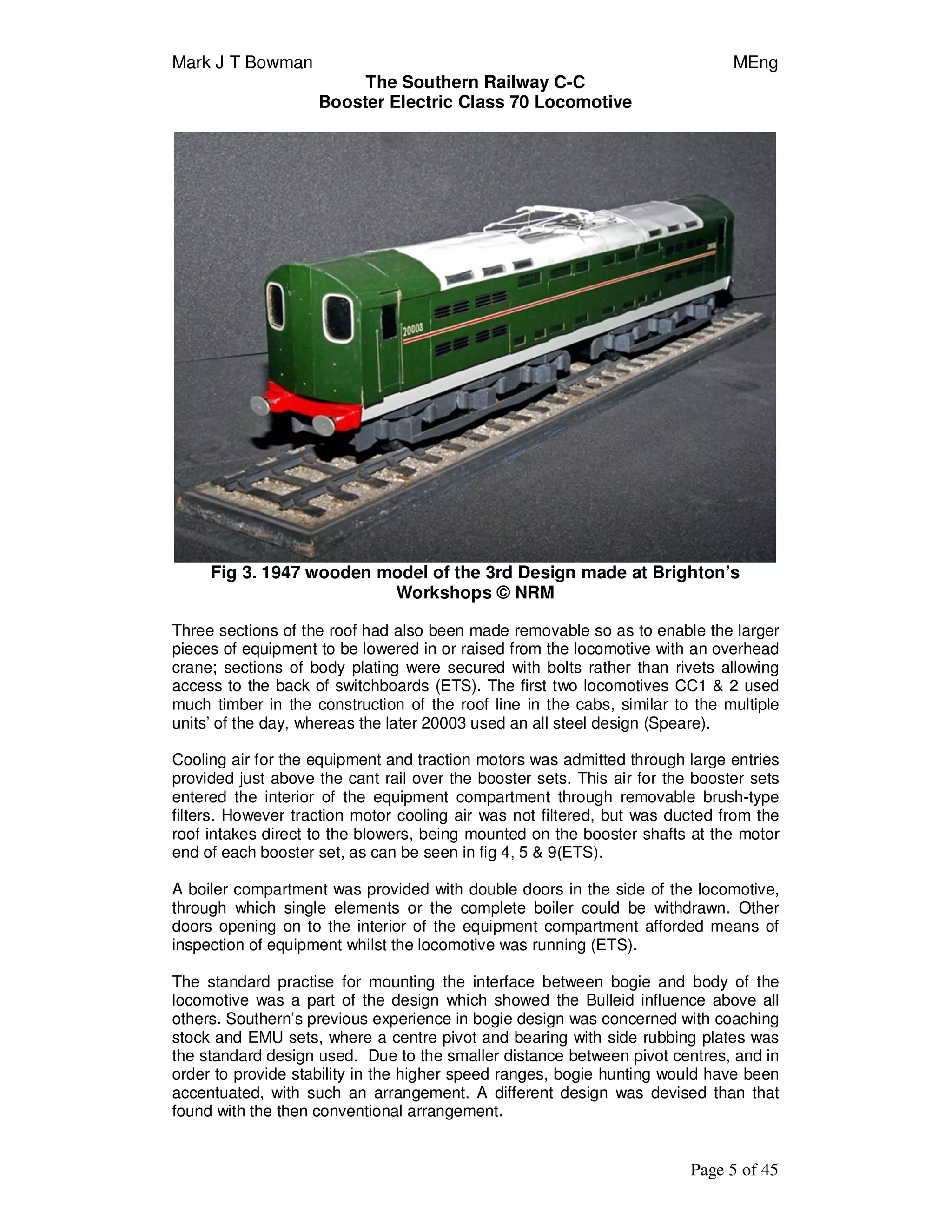

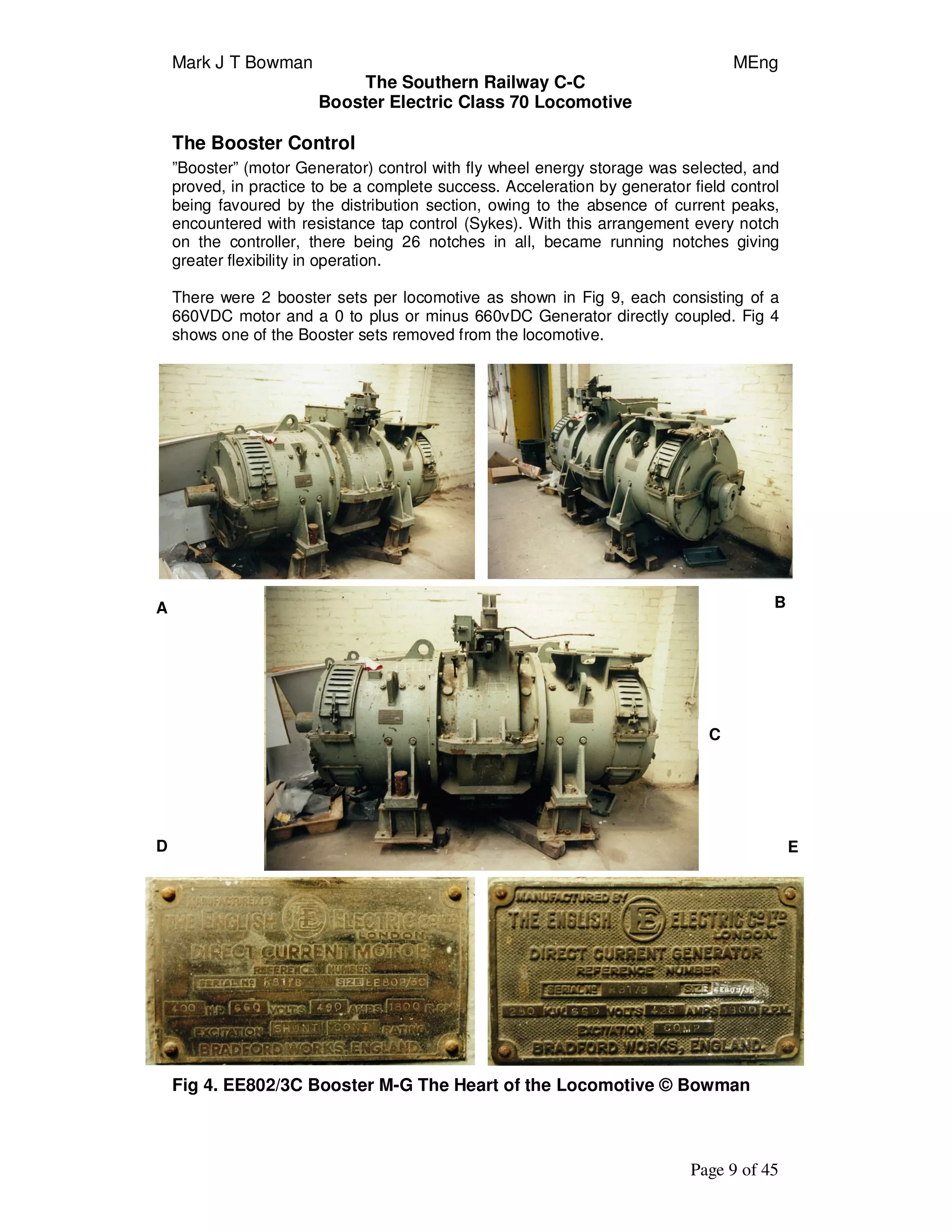

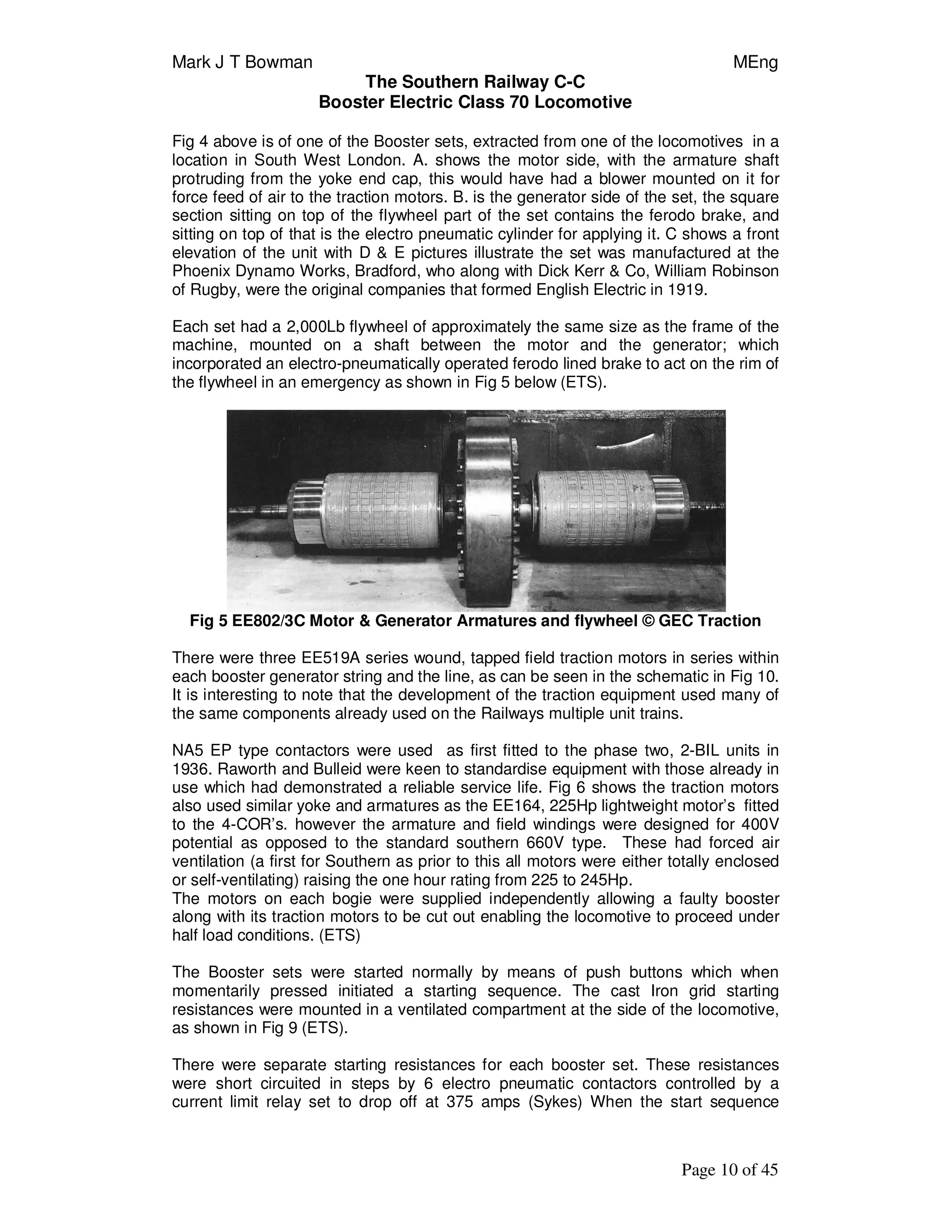

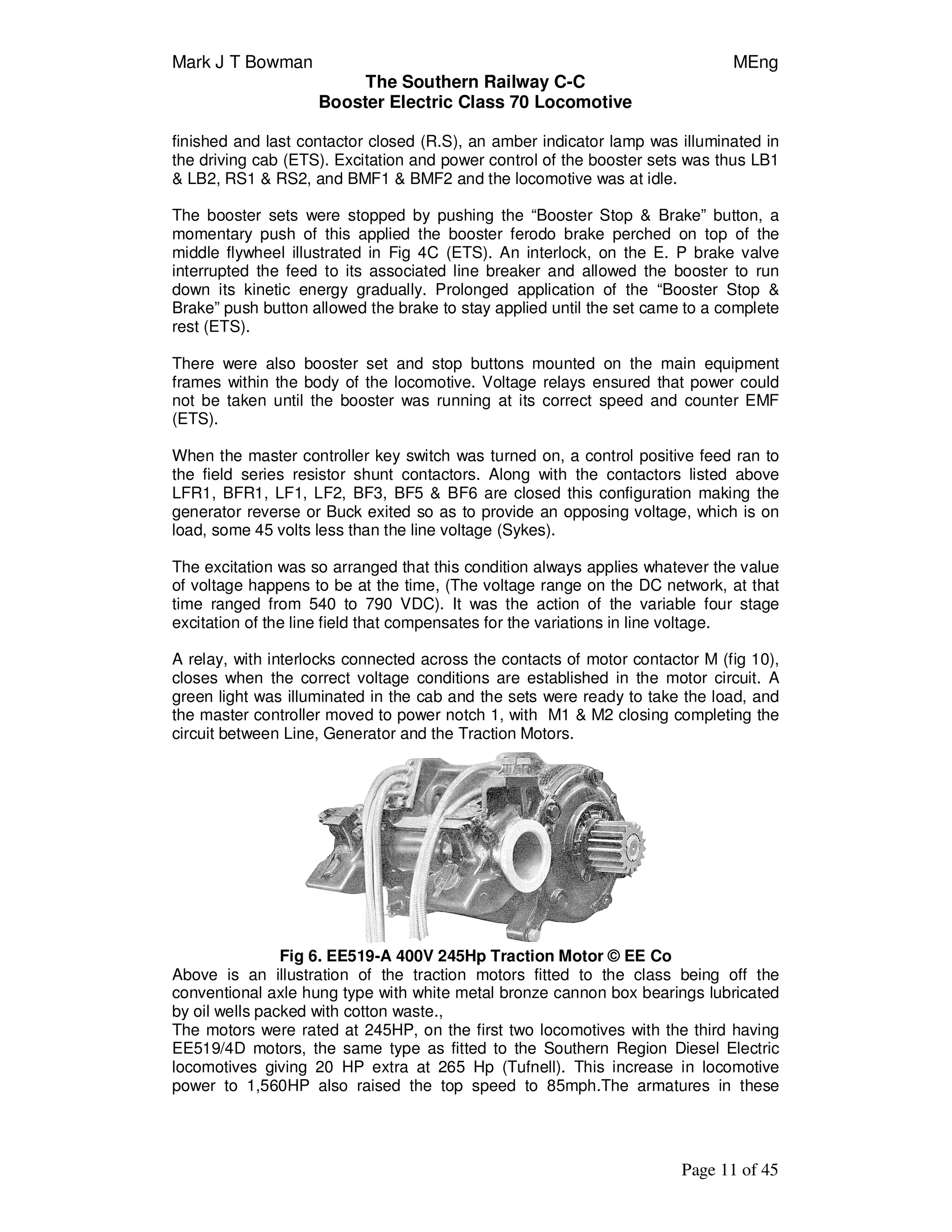

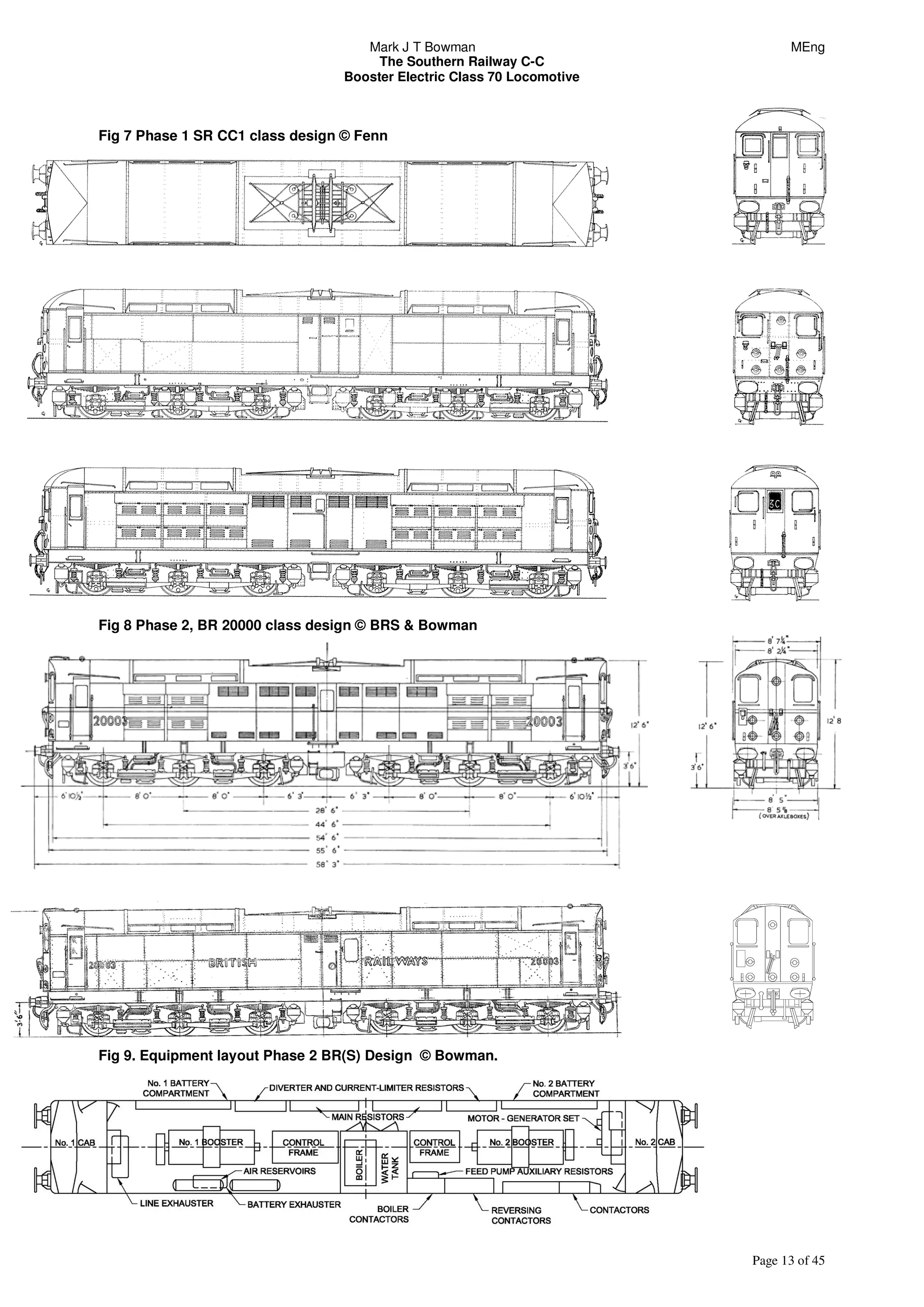

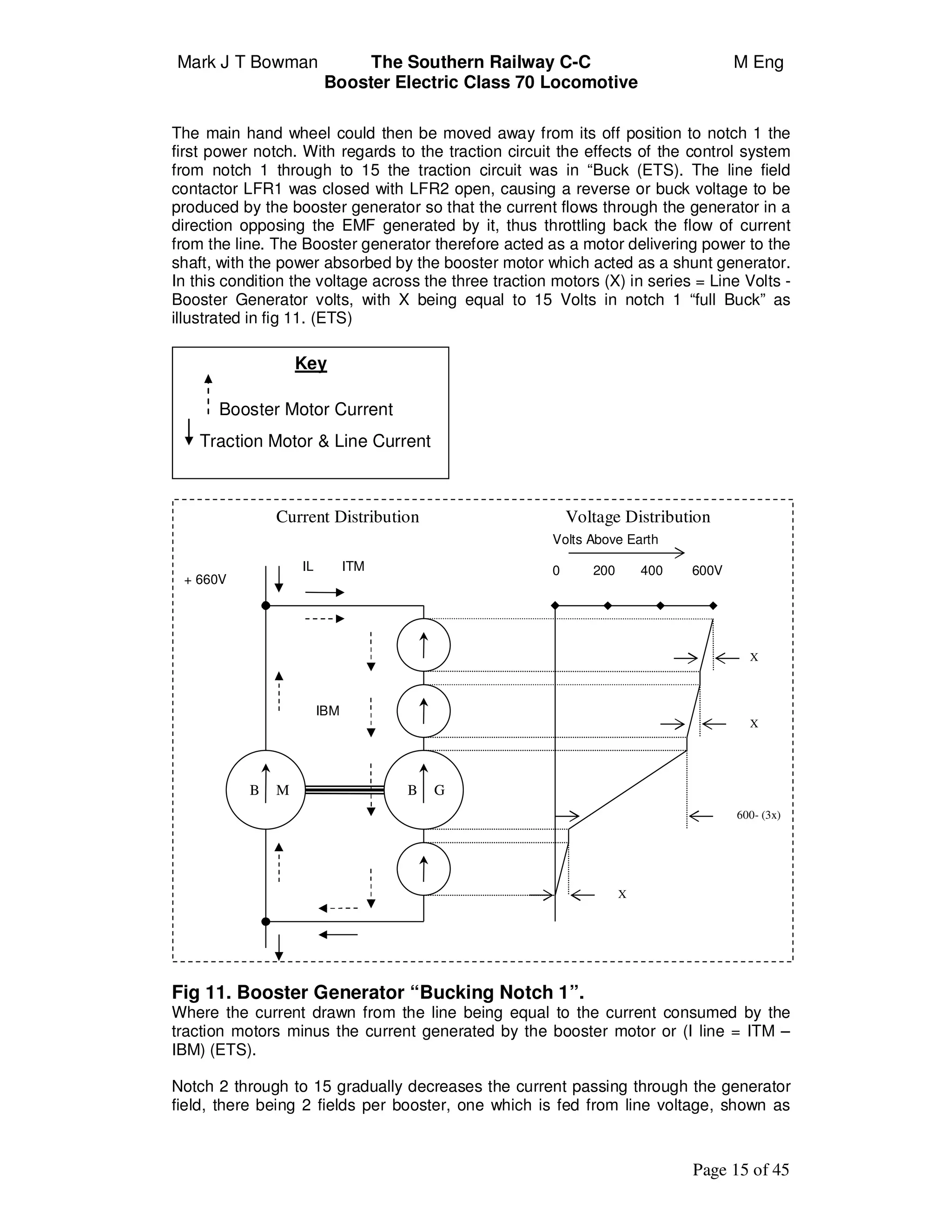

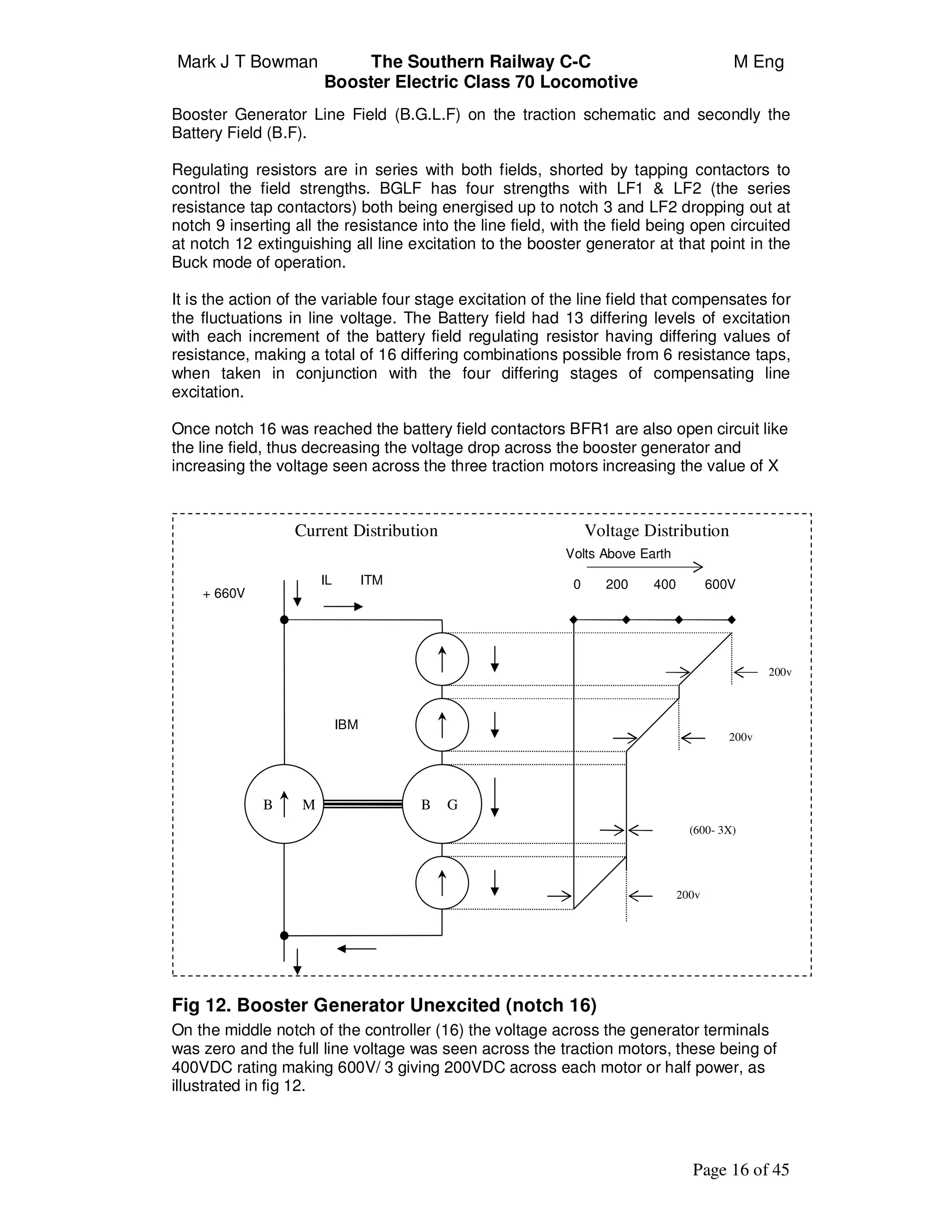

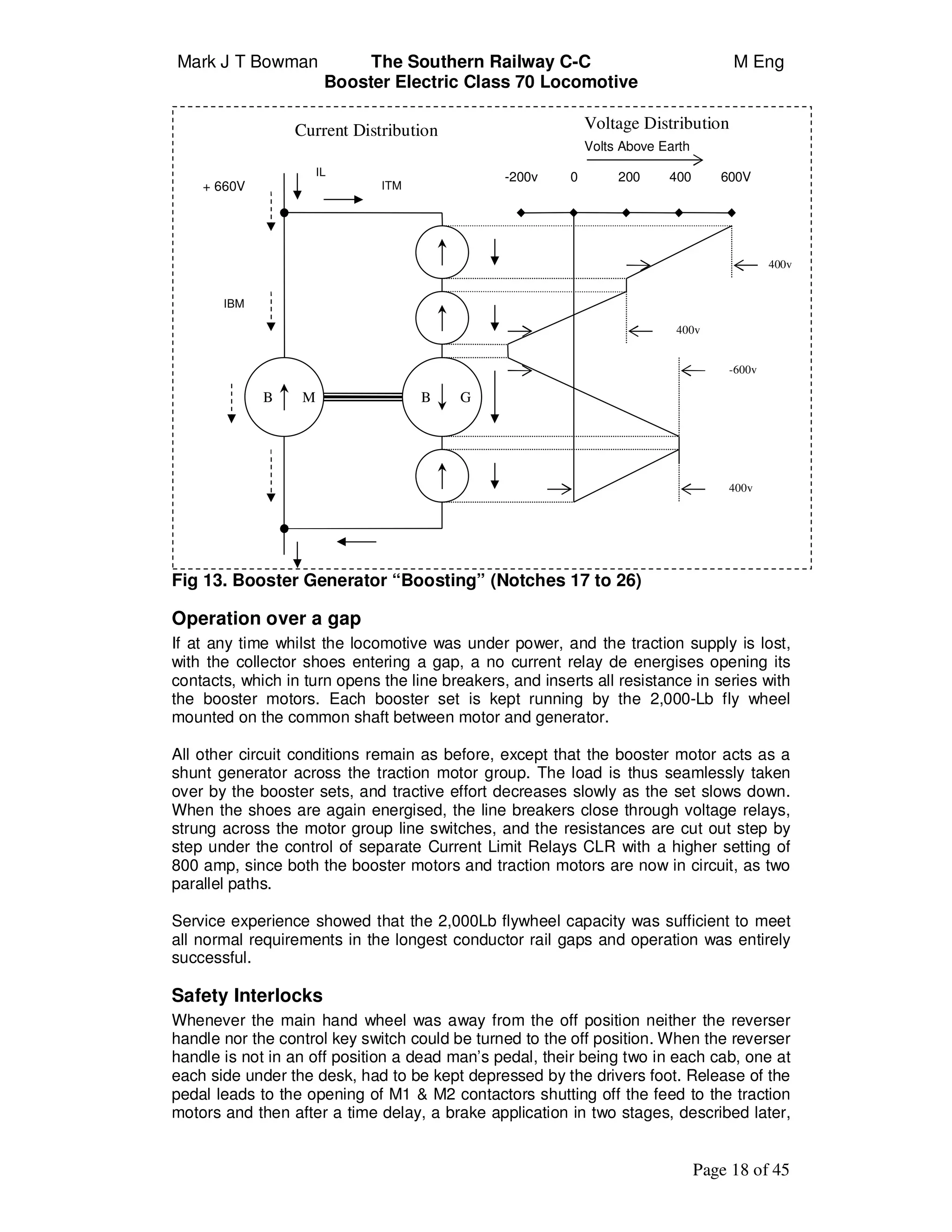

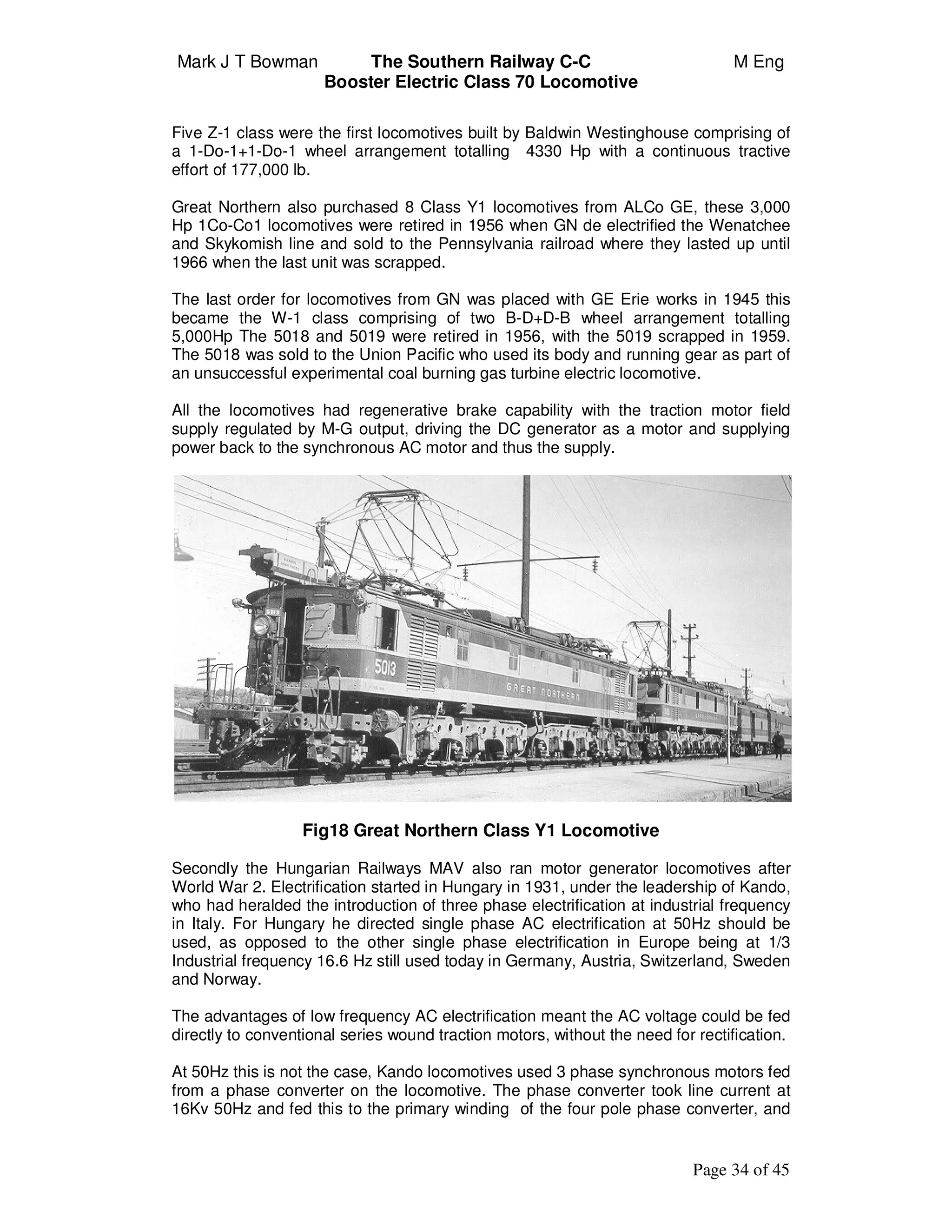

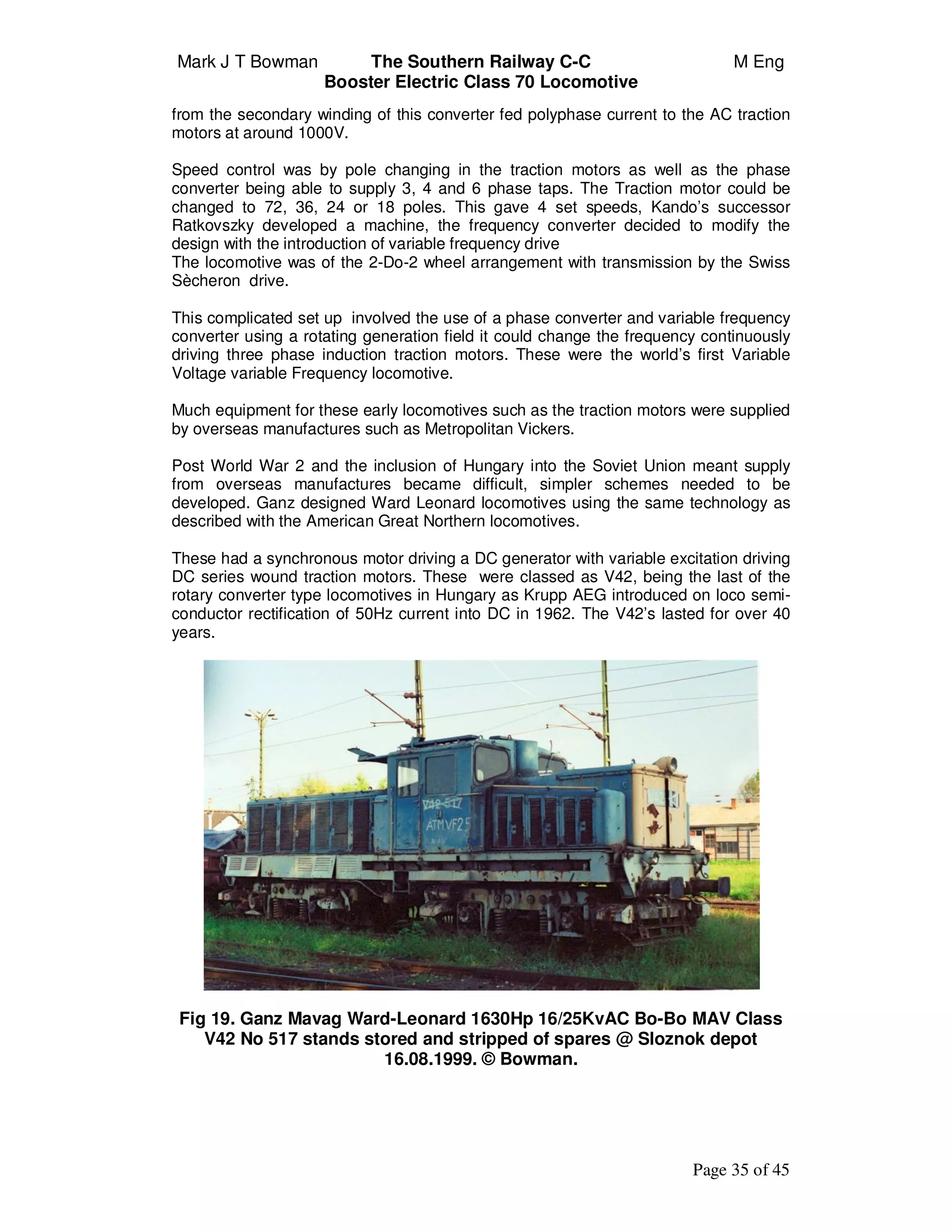

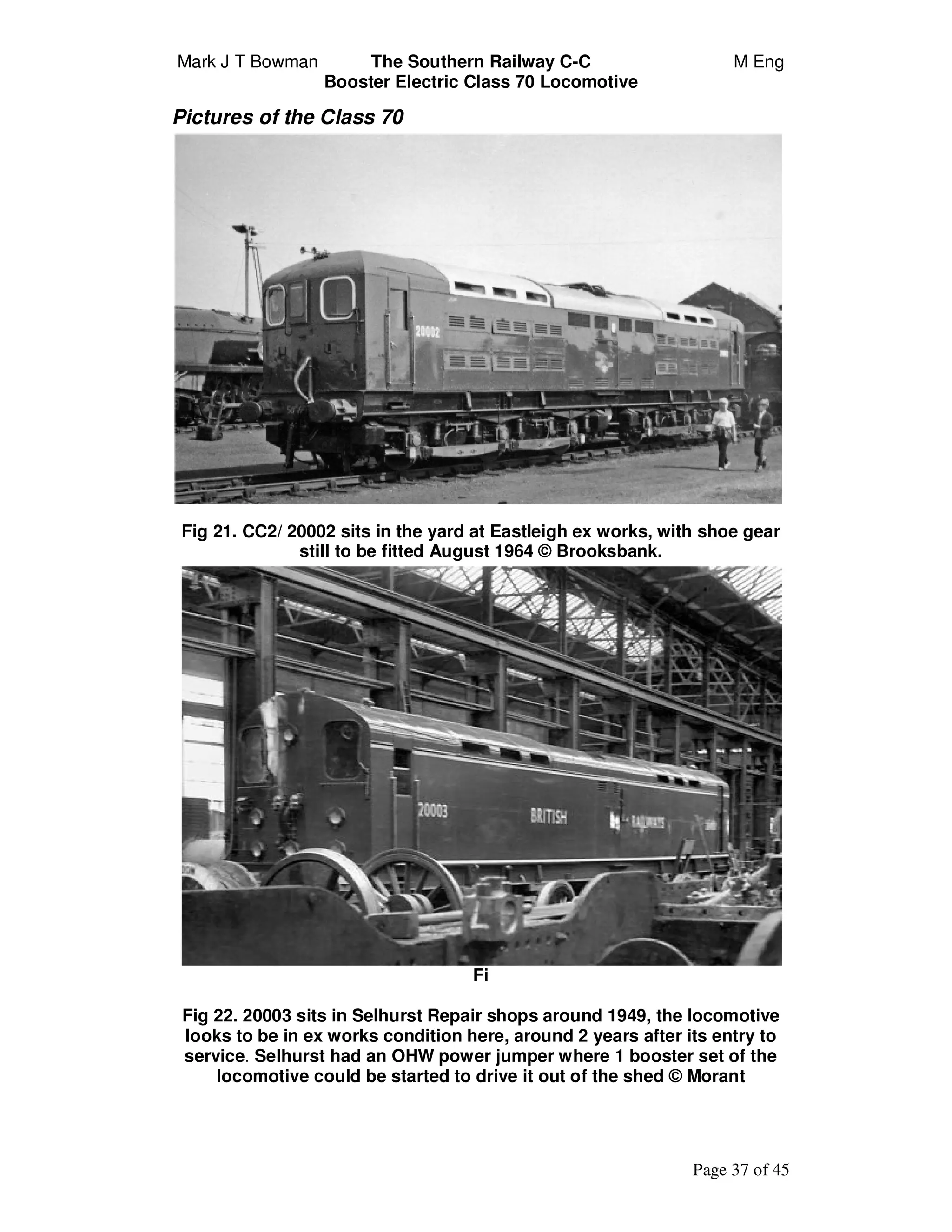

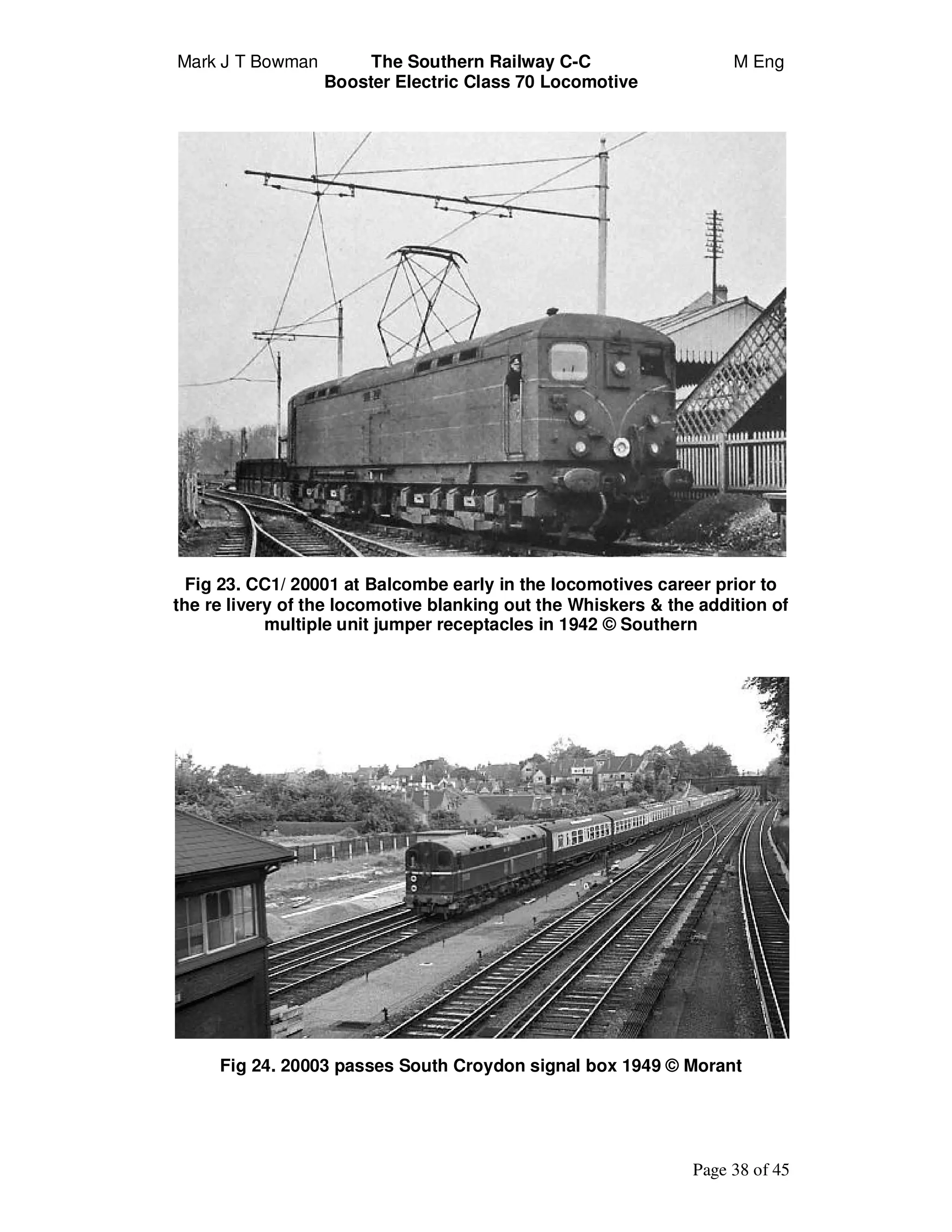

The document summarizes the design and development of the Southern Railway's C-C Booster Electric Class 70 Locomotive. It describes the locomotive's Co-Co wheel arrangement, segmented bearing bogie design influenced by O.V.S Bulleid, and its electrical system including a unique booster control system designed by Alfred Raworth to provide continuous tractive effort despite gaps in the third rail power supply. The locomotive had three builds between 1936-1948 with improvements incorporated based on experience. The booster system drew from earlier work by Heilmann and Ward Leonard to effectively control the locomotive using intermittent third rail power.