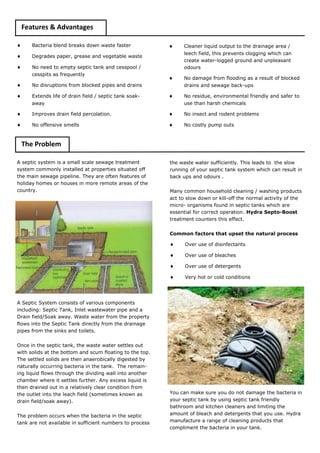

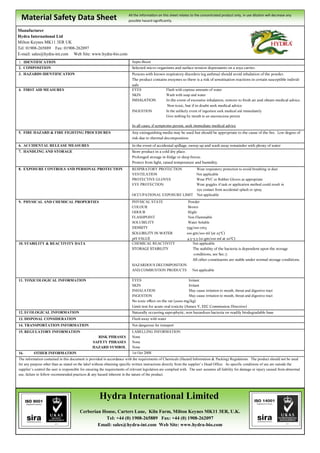

Hydra Septo-Boost is a concentrated biological treatment designed to enhance the performance of septic systems by utilizing a blend of microorganisms, enzymes, and nutrients to break down waste more effectively. The product reduces the frequency of septic tank emptying, prevents clogs and odors, and maintains efficient drainage in septic and cesspool systems. It is available in water-soluble sachets for easy application and is safe to use alongside various household cleaning products.