F gas logbook mitie (1)

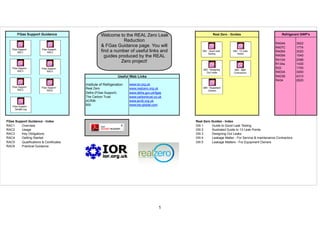

- 1. FGas Support Guidance Real Zero - Guides Refrigerant GWP's R404A 3922 R407C 1774 R408A 3020 R409A 1540 R410A 2088 R134a 1430 R22 1700 R403A 3000 Useful Web Links R403B 4310 R434 2620 Institute of Refrigeration www.ior.org.uk Real Zero www.realzero.org.uk Defra (FGas Support) www.defra.gov.uk/fgas The Carbon Trust www.carbontrust.co.uk ACRIB www.acrib.org.uk BSI www.bsi-global.com FGas Support Guidance - Index Real Zero Guides - Index RAC1 Overview GN 1 Guide to Good Leak Testing RAC2 Usage GN 2 Illustrated Guide to 13 Leak Points RAC3 Key Obligations GN 3 Designing Out Leaks RAC4 Getting Started GN 4 Leakage Matter - For Service & maintenance Contractors RAC5 Qualifications & Certificates GN 5 Leakage Matters - For Equipment Owners RAC6 Practical Guidance Welcome to the REAL Zero Leak Reduction & FGas Guidance page. You will find a number of useful links and guides produced by the REAL Zero project! FGas Support - RAC1 FGas Support - RAC2 FGas Support - RAC3 FGas Support - RAC4 FGas Support - RAC5 FGas Support - RAC6 FGas Support - Sample Log GN2 - 13 Leak Points GN1 - Good Leak Testing GN3 - Designing Out Leaks GN4 - S&M Contractors GN5 - Equipment Owners 1

- 2. FGas Usage Summary Graph RerigerantUsage(kg) 0 30 60 90 120 Systems System 1 System 2 System 3 System 4 System 5 System 6 System 7 System 8 System 9 System 10 2.75 0.75 104 1

- 3. FGas Log & Direct CO2 Emission Calculator Welcome to the REAL Zero FGas logging sheet. Please follow the below instructions carefully and check your data is linked correctly by trying some test data. Good luck with leakage reduction! Institute of Refrigeration (IoR) REAL Zero Project Site Name: Site Address: Instructions Period Recorded From: 01/01/2019 To: 01/07/2019 Enter date span of the report dd/mm/yyyy Your Logo Here Refrigerant Type R134a R404A R22 R407C R410A % of Charge Lost Per System Enter your refrigerant type here Cost per kg £ 55.00 £ 90.00 £ - £ 40.00 £ 60.00 Enter the cost per kg of refrigerant Global Warming Potential (EN378-1:2008) 1300 3780 1700 1650 1980 If the refrigerant and GWP is not on the summary sheet get the data from the 'Information' sheet and over write it. System 1 104.00 0% To link the individual system pages (tabs) to the summary page please follow the below instructions:System 2 0.75 0% System 3 2.75 0% 1. Single 'click' on the system number cell under the corresponding refrigerant type to be totalled System 4 System 5 2. Enter = into the cell and go to the relevant system tab at the bottom of the page System 6 0% System 7 3. Single click on the 'Actual Loss' refrigerant used total cell and enter (return Key) on that cell - Red CellSystem 8 System 9 The refrigerant usage total for that system will then populate the corresponding total box on the summary sheetSystem 10 Total Loss (by refrigerant type) 104.00 0.00 0.00 0.75 2.75 Ver: 2.50CO2 Equivalent Tonnes (by refrigerant type) 135.20 0.00 0.00 1.24 5.45 Cost of Refrigerant (by refrigerant type) £5,720 £0 £0 £30 £165 No of Days Report Covers 181d Note: The accuracy of the totals displayed on this page rely on the correct linking of the spreadsheet as per the instructions.Total Carbon Emissions Tonnes (all systems) 142 Total Cost of Refrigerant (all systems) £5,915 The total refrigerant used, cost, carbon emissions and % lost are over the period of days covered by the report and are not annualizedTotal Refrigerant Used kg (all systems) 107.50 Total Entrained Volume kg (all systems) 112.50 Cell errors will be visible on this sheet until it is linked to 'System' sheets Total % of Refrigerant Lost (all systems) 96% Disclaimer: The IOR can accept no liability for any errors or omissions The Carbon Trust works with groups of organisations to reduce carbon emissions and costs The refrigerant leakage recorded on this log is equivalent to driving a typical van 567,530 miles Developed by S J Benton - Cool Concerns Ltd FGas Usage Logging Spread Sheet Summary FGas Usage SheetF Gas Logbook Mitie (1).xls17:1325/06/2019

- 4. General Information Plant Name: CHILLER Reference No. ALS229.2XE ST Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: R134A Refrigerant Quantity (Entrained Volume) kg: 104.00 Plant Manufacturer: McQuay Year of Installation: 2001 Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) 0% Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 01/06/2019 ANTHONY WOOTTON GOOD NONE FGas Log Incl GWP Calculator 1

- 5. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments FGas Log Incl GWP Calculator 2

- 6. General Information Plant Name: AC 1 Reference No. RSGZ7V11 (S/N - 5200007) Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: R407C Refrigerant Quantity (Entrained Volume) kg: 0.75 Plant Manufacturer: DAIKIN Year of Installation: 2002 Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) 0% Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 01/06/2019 ANTHONY WOOTTON GOOD NONE 1

- 7. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 8. 3

- 9. 4

- 10. General Information Plant Name: AC 2 Reference No. RZQ71C7V1B (S/N - 1804924) Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: R410A Refrigerant Quantity (Entrained Volume) kg: 2.75 Plant Manufacturer: DAIKIN Year of Installation: 2008 Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) 0% Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 22/02/2014 ANTHONY WOOTTON GOOD NONE 1

- 11. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 12. 3

- 13. 4

- 14. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 15. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 16. 3

- 17. 4

- 18. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 19. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 20. 3

- 21. 4

- 22. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: 5.00 Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) 0% Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 23. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 24. 3

- 25. 4

- 26. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 27. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 28. 3

- 29. 4

- 30. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: 0.00 Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 31. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 32. Reason for Addition val (including what was done with recovered refrigerant) Follow Up Actions Required 3

- 34. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: 0.00 Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 35. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 36. Reason for Addition val (including what was done with recovered refrigerant) Follow Up Actions Required 3

- 38. General Information Plant Name: Reference No. Location of Plant: Plant Operator (name, address, telephone): Operator Contact: Cooling Loads Served: Refrigerant Type: Refrigerant Quantity (Entrained Volume) kg: 0.00 Plant Manufacturer: Year of Installation: Refrigerant Additions Date Technician/Company Amount Added (kg) Reason for Addition Total Additions 0.00 Actual Loss kg's - Net Diff (additions minus removals) 0 Percentage of System Charge Lost (entrained volume) Refrigerant Removals Date Technician/Company Amount Removed (kg) Reason for Removal (including what was done with recovered refrigerant) Total 0.00 Leak Tests Date Technician/Company Test Result (including location & cause of any leaks identified) Follow Up Actions Required 1

- 39. Follow-up Actions Date Technician/Company Related to Test on dd/ mm/yyyy Actions Taken Testing of automatic Leak Detection Systems (if fitted) Date Technician/Company Test Result Comments 2

- 40. Reason for Addition val (including what was done with recovered refrigerant) Follow Up Actions Required 3

- 42. 1