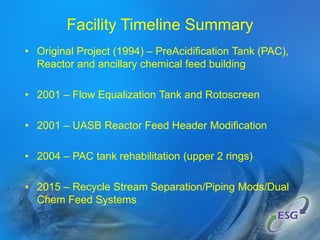

This document provides an overview and summary of the Rockdale Water Resources UASB Pretreatment Facility. It discusses the origins and timeline of the facility from 1994 to present, including various process and operational changes. The key points are:

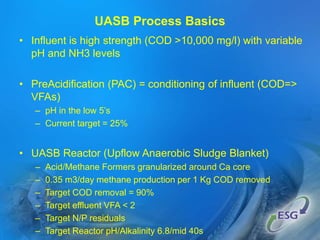

- The UASB process involves pre-acidification of high-strength influent to produce volatile fatty acids, which are then treated in an upflow anaerobic sludge blanket reactor to remove 90% of COD and produce methane gas.

- Operational changes from 2014 to present included separating the recycle stream, adding independent dual nutrient feeds, and making process changes driven by dissolved oxygen and nutrient residuals.

- Planned changes moving forward include improving biogas controls