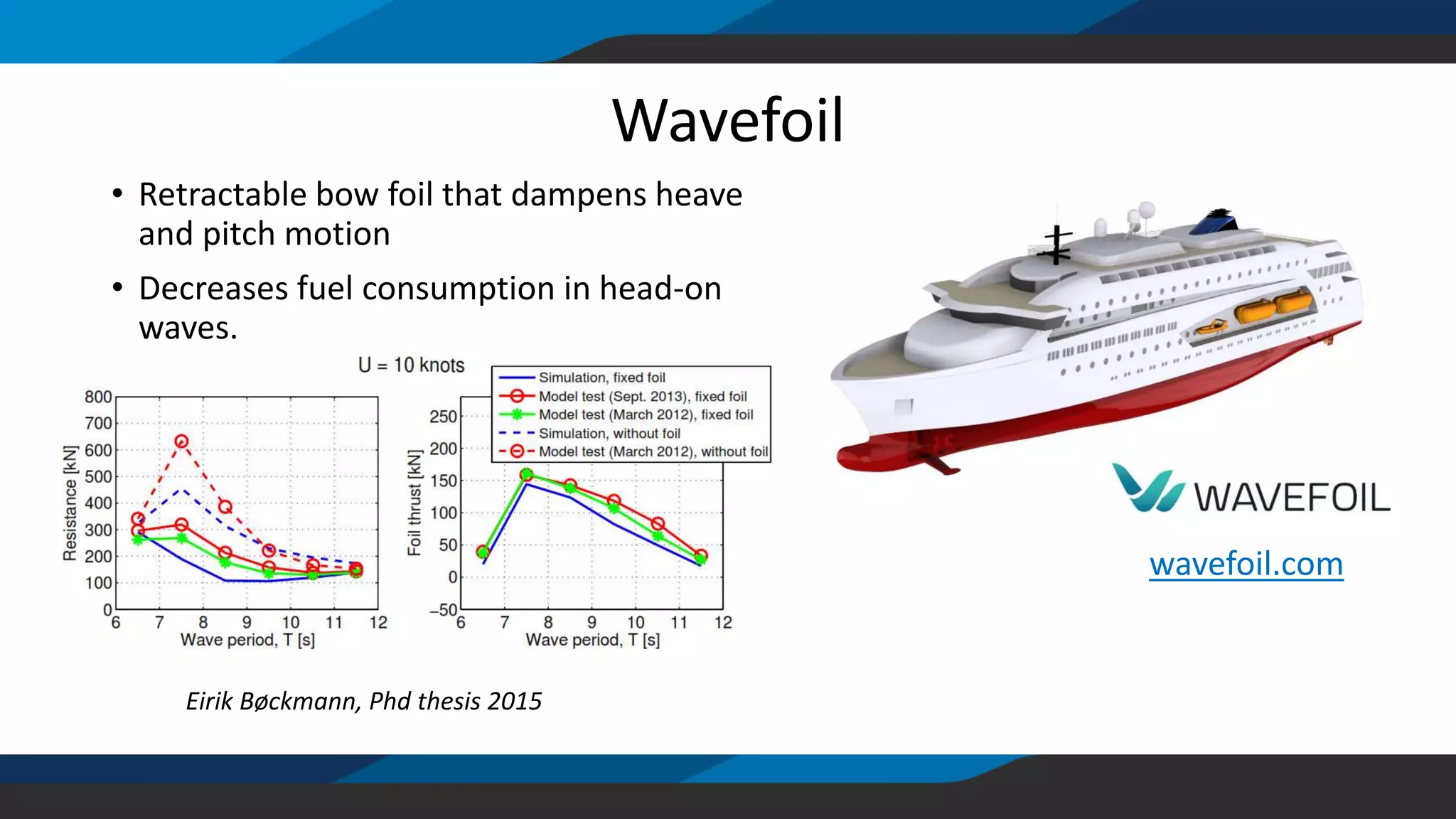

This document summarizes a fluid-structure interaction (FSI) analysis of a composite bow foil. The analysis compared a quasi-static structural analysis, dynamic structural analysis with rigid CFD, and a full FSI analysis with two-way fluid-structure coupling. The FSI analysis found a 40-50% reduction in bending moment and vertical force compared to the quasi-static analysis. Compressible air effects provided a minor 10% difference from an incompressible analysis. The hydroelasticity parameter indicated structural dynamics were important given the short load duration. Overall, the FSI and dynamic analyses provided a lighter and more optimized structural design compared to a traditional quasi-static approach.

![Time step convergence

0

0.2

0.4

0.6

0.8

1

1.2

0.00E+00 2.00E-05 4.00E-05 6.00E-05 8.00E-05 1.00E-04 1.20E-04

Verticalforce/CFL

Timestep [s]

Vertical force CFL

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

0.035 0.037 0.039 0.041 0.043 0.045 0.047

Verticalforce[MN]

Time [s]

dt=1e-4 dt=2.5e-5 dt=1e-5

• CFL < 1 gives sufficient accuracy on forces (average of pressure)](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-7-2048.jpg)

![Validation of FSI model

Experimental data from Panciroli et al. 2012

-0.002

-0.0015

-0.001

-0.0005

0

0.0005

0.001

0.0015

0.002

0.0025

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07

Strain[%]

Time[s]

FSI (CFD)

Experiment (Panciroli)

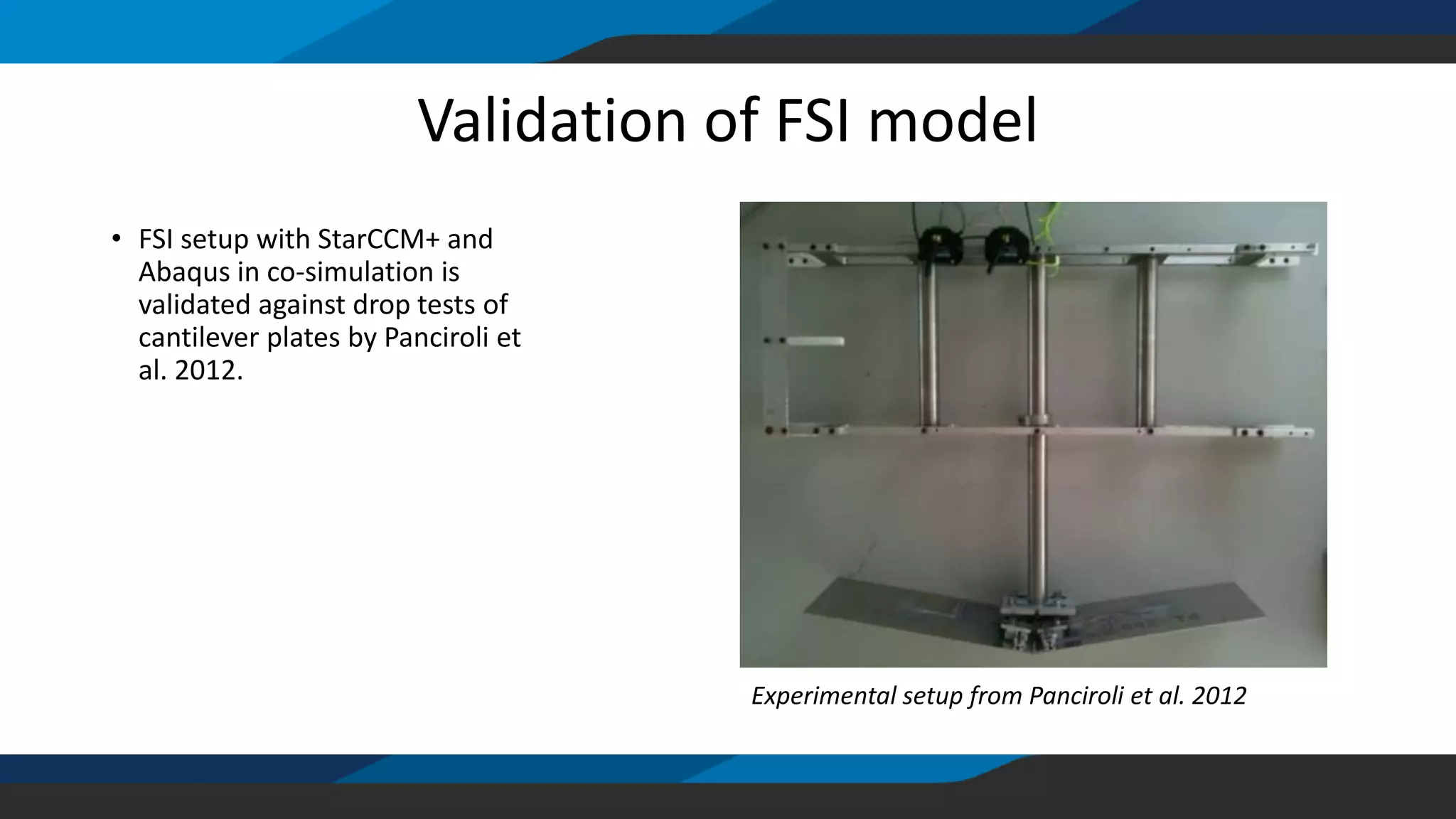

• FSI setup with StarCCM+ and

Abaqus in co-simulation is

validated against drop tests of

cantilever plates by Panciroli et

al. 2012.](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-12-2048.jpg)

![Results - compressible air effects

• FSI versus quasi-static yields

reduction of bending moment of

50%

• Dynamic vs quasi-static yields

reduction of bending moment of

50%

-0.9

-0.7

-0.5

-0.3

-0.1

0.1

0.3

0.5

0.7

0.9

1.1

1.3

1.5

1.7

1.9

2.1

0.02 0.025 0.03 0.035 0.04 0.045 0.05 0.055 0.06 0.065

Verticalforce[MN]

Time [s]

Quasi-static Quasi-static (incompressible air)

• Compressible air effects are

relevant

• Part of Hull adjacent to foil

needs to be included in CFD

model](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-13-2048.jpg)

![• FSI approach renders vertical

force about 40% of quasi-static

• Dynamic approach gives spurious

oscillations because of no

damping

-0.9

-0.7

-0.5

-0.3

-0.1

0.1

0.3

0.5

0.7

0.9

1.1

1.3

1.5

1.7

1.9

2.1

0.02 0.025 0.03 0.035 0.04 0.045 0.05 0.055 0.06 0.065Verticalforce[MN]

Time [s]

Quasi-static FSI Dynamic

Results – vertical force](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-14-2048.jpg)

![• FSI bending moment about 40% of

quasi-static

• Dynamic bending moment about

60% of quasi-static

• Incompressible air effects yields

only 10% difference to FSI bending

moment

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

0.02 0.025 0.03 0.035 0.04 0.045 0.05 0.055 0.06 0.065

Bendingmoment[MNm]

Time [s]

Quasi-static FSI (two-way coupling) Dynamic (One-way coupling) FSI (incompressible)

Results – bending moment](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-15-2048.jpg)

![The role of hydroelasticity

-0.9

-0.7

-0.5

-0.3

-0.1

0.1

0.3

0.5

0.7

0.9

1.1

1.3

1.5

1.7

1.9

2.1

0.02 0.022 0.024 0.026 0.028 0.03 0.032 0.034 0.036 0.038 0.04 0.042 0.044 0.046 0.048 0.05 0.052 0.054 0.056 0.058 0.06 0.062 0.064

Verticalforce[MN]

Time [s]

Quasi-static

Duration=5-10 ms

R=0.2-0.3

Hydroelasticity parameter:

R =

𝑙𝑜𝑎𝑑 𝑑𝑢𝑟𝑎𝑡𝑖𝑜𝑛 (𝑟𝑖𝑔𝑖𝑑 𝑠𝑡𝑟𝑢𝑐𝑡𝑢𝑟𝑒)

𝑝𝑒𝑟𝑖𝑜𝑑 𝑜𝑓 1𝑠𝑡 𝑑𝑟𝑦/𝑤𝑒𝑡 𝑚𝑜𝑑𝑒

R < 1-2: hydroelastic effects are relevant

(Faltinsen 1999, Bereznitski 2001)](https://image.slidesharecdn.com/nafemsnordic2018-180427090906/75/cDynamics-AS-NAFEMS-Nordic-2018-Presentation-20-2048.jpg)