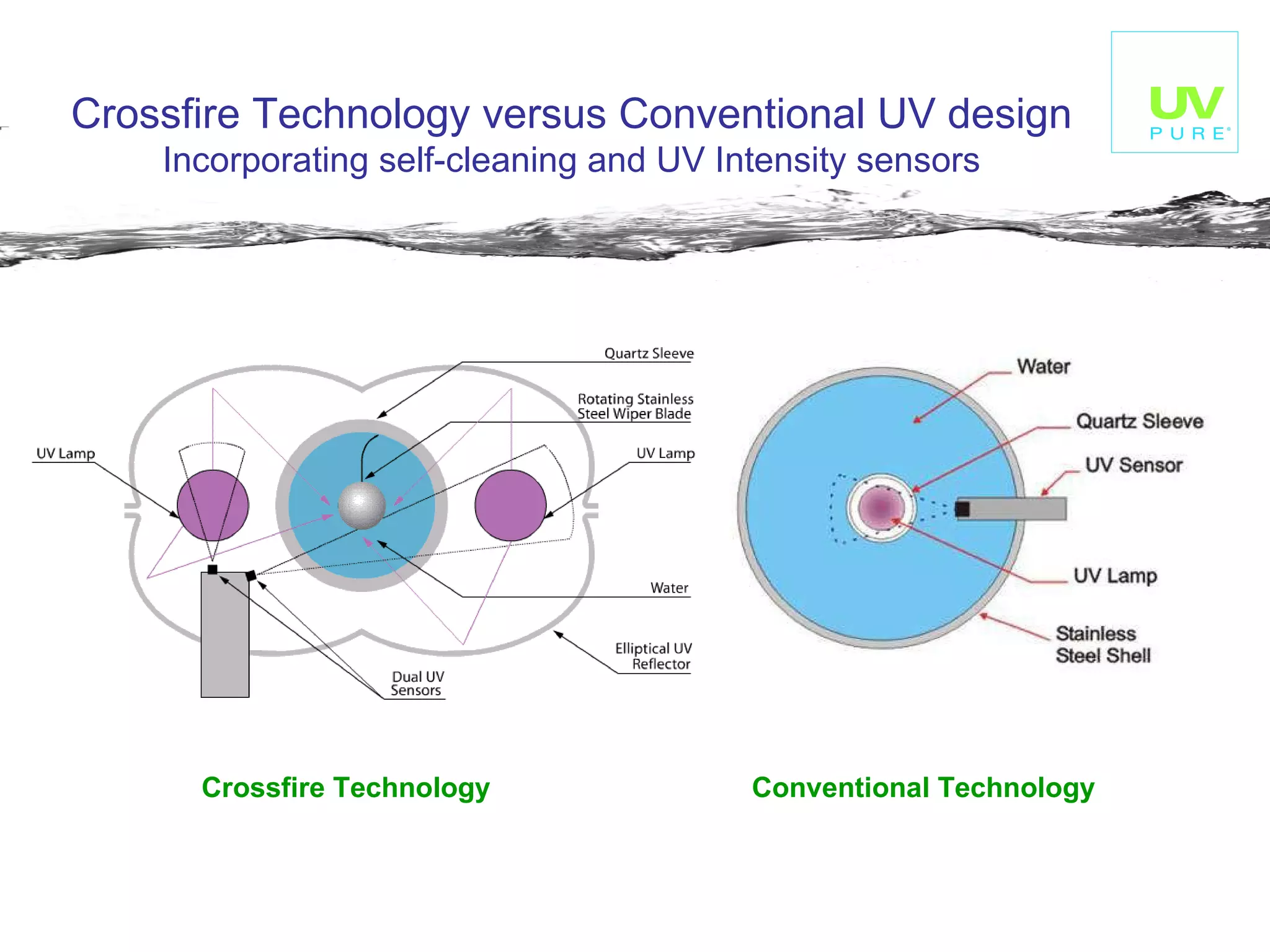

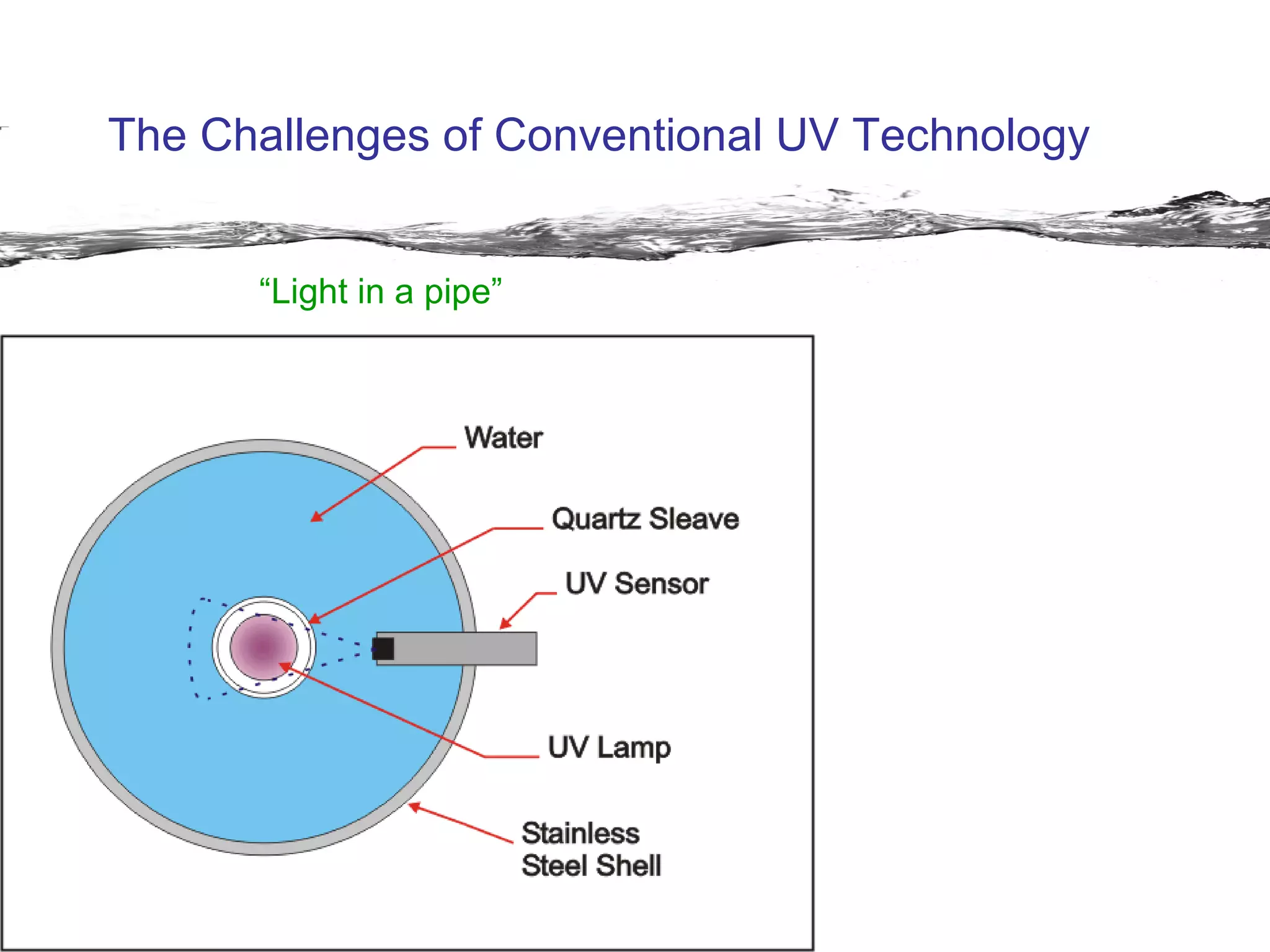

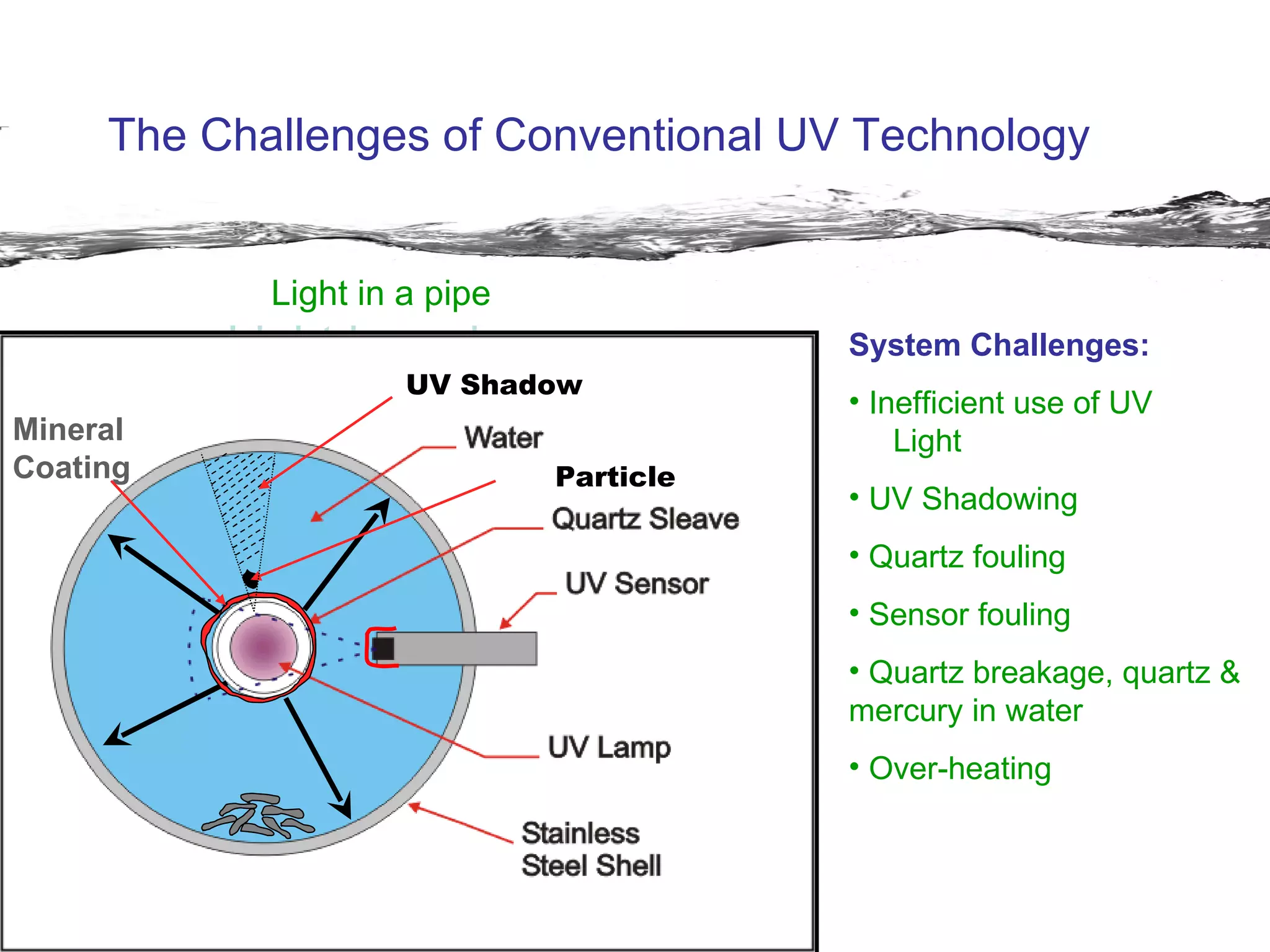

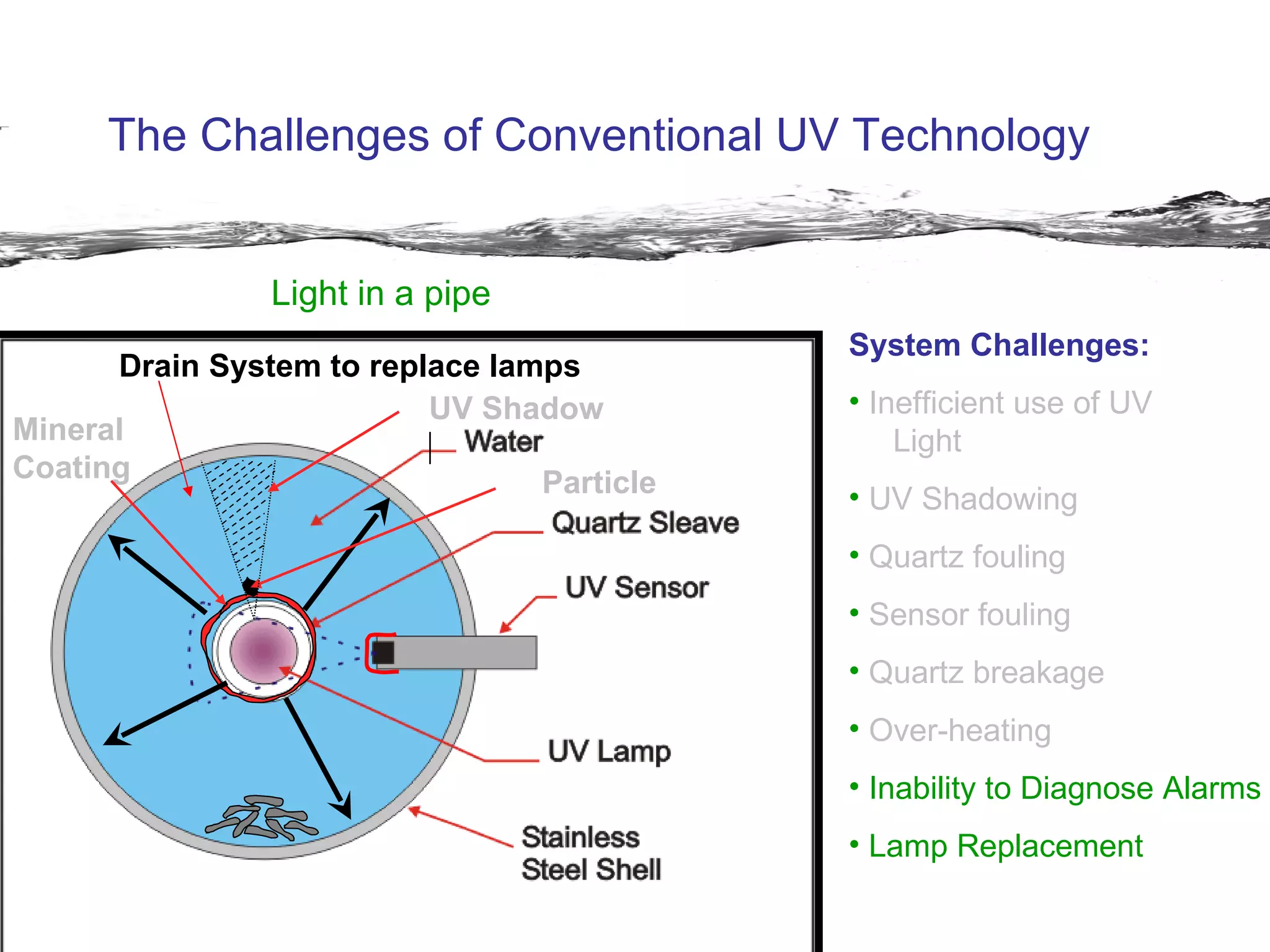

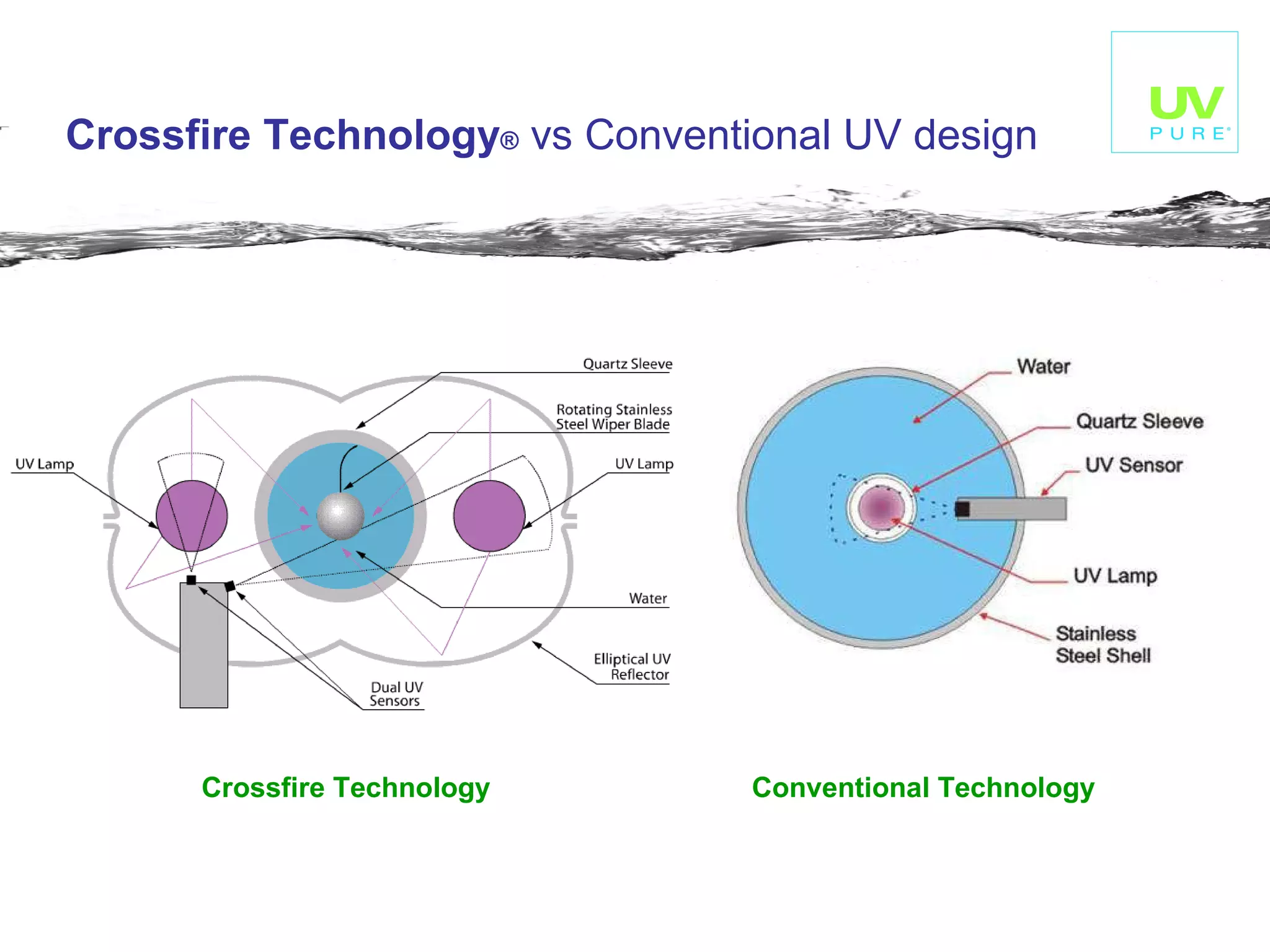

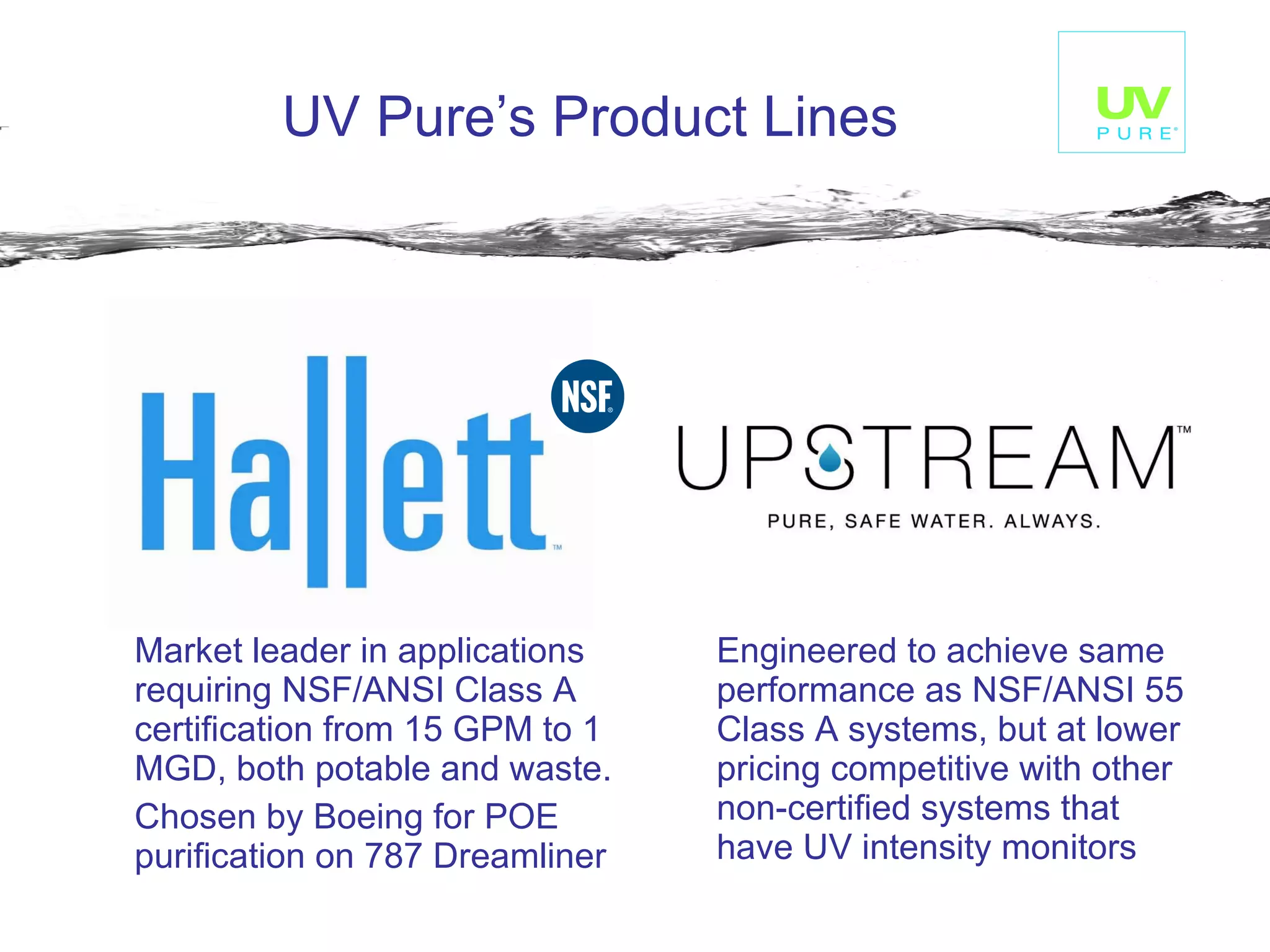

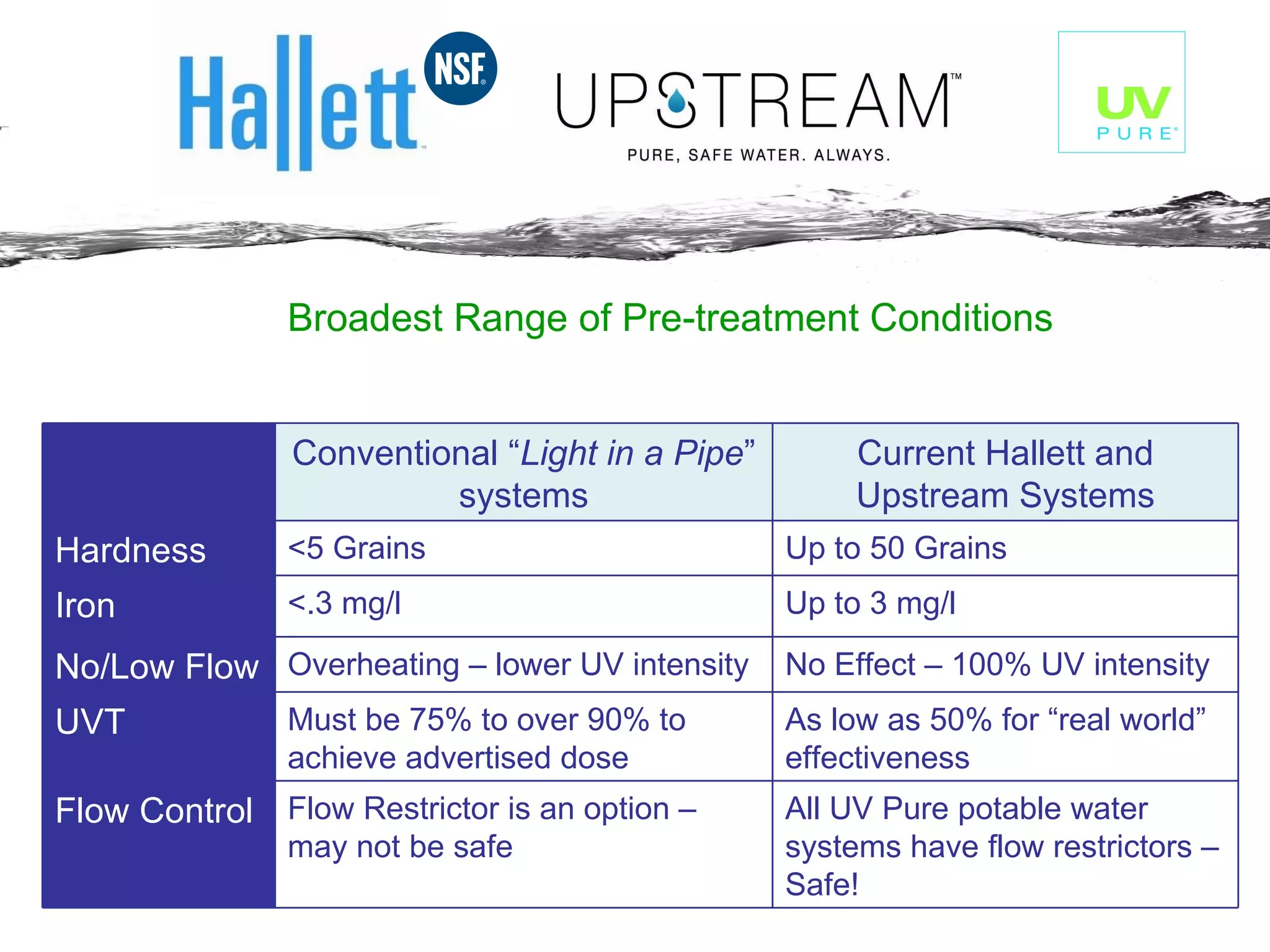

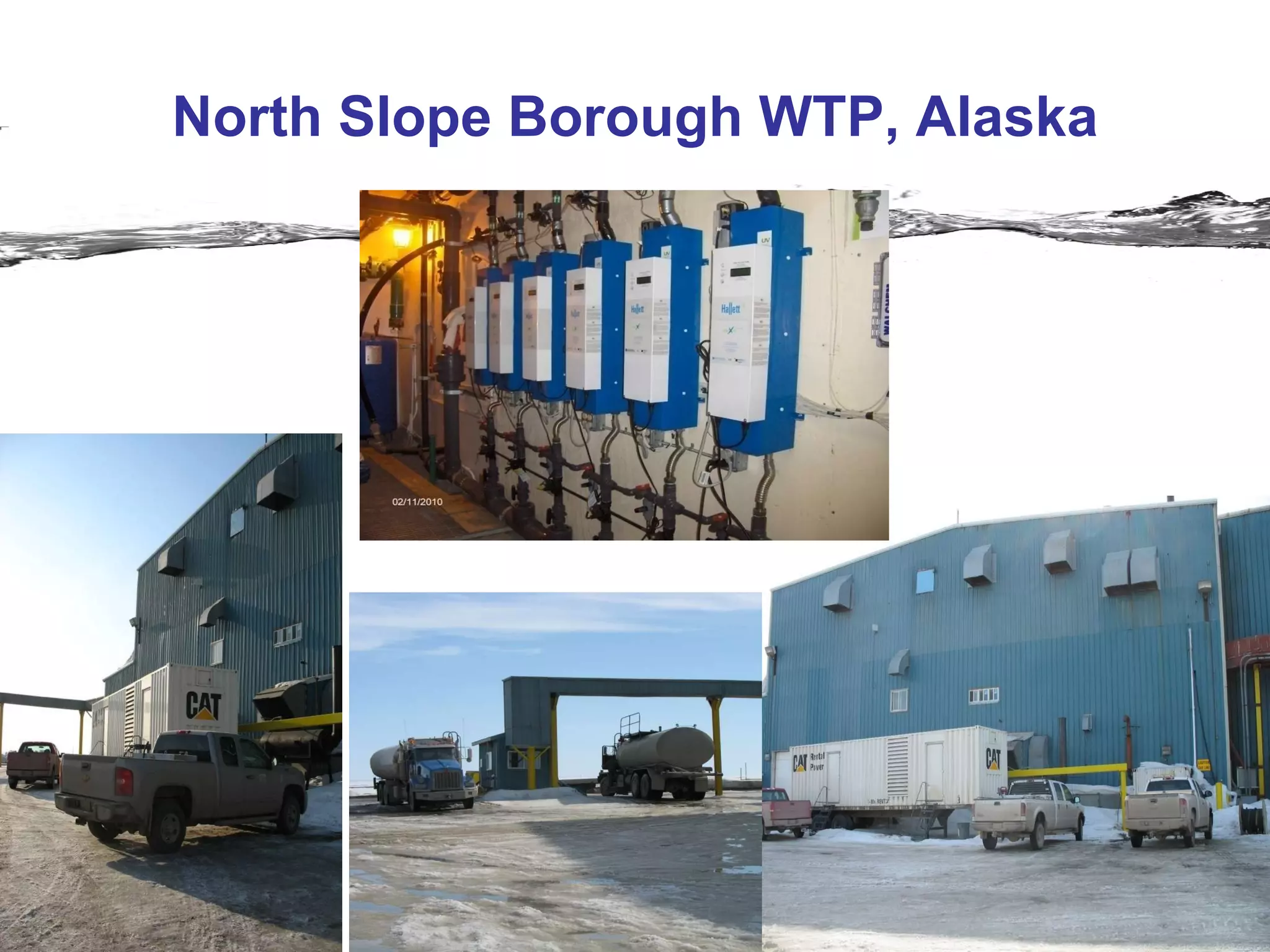

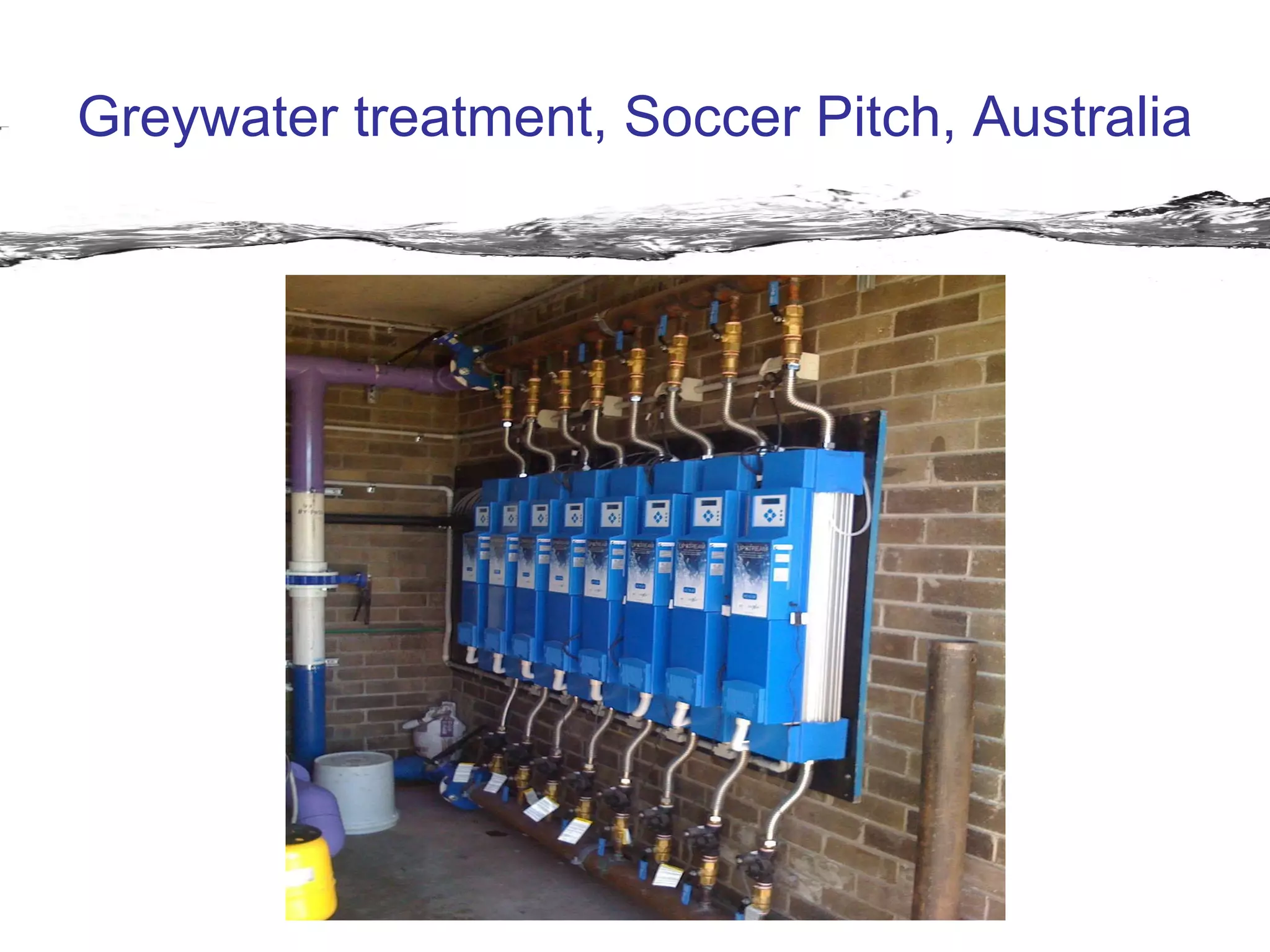

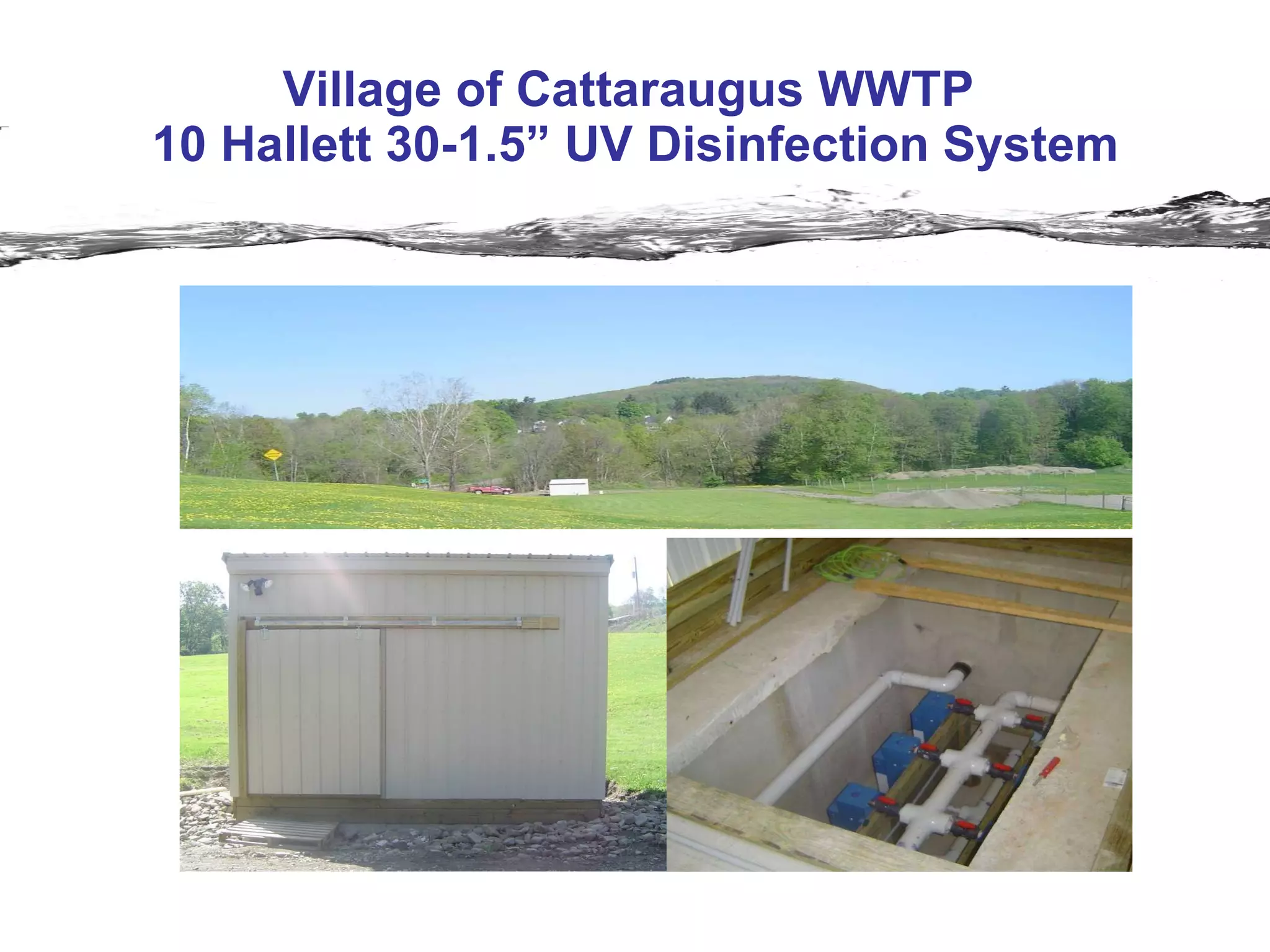

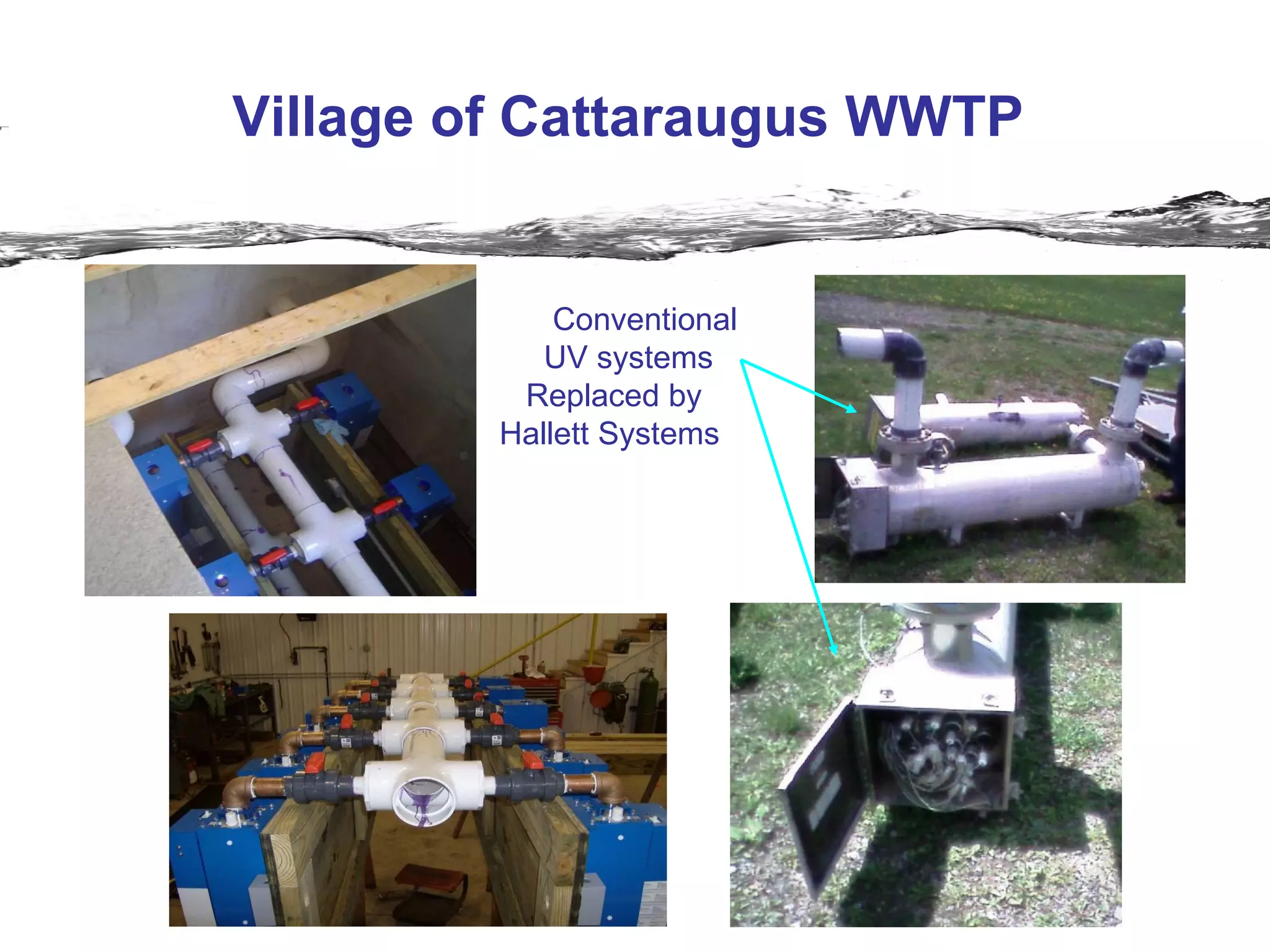

UV Pure Technologies develops UV disinfection systems using patented Crossfire Technology. The document discusses UV Pure's awards, customers, market focus on small decentralized applications, and how its Crossfire Technology offers advantages over conventional UV designs through features like self-cleaning elliptical reflectors and dual smart sensors. UV Pure offers a broad range of product lines for potable, wastewater, and reuse applications from 15 GPM to 1 MGD.