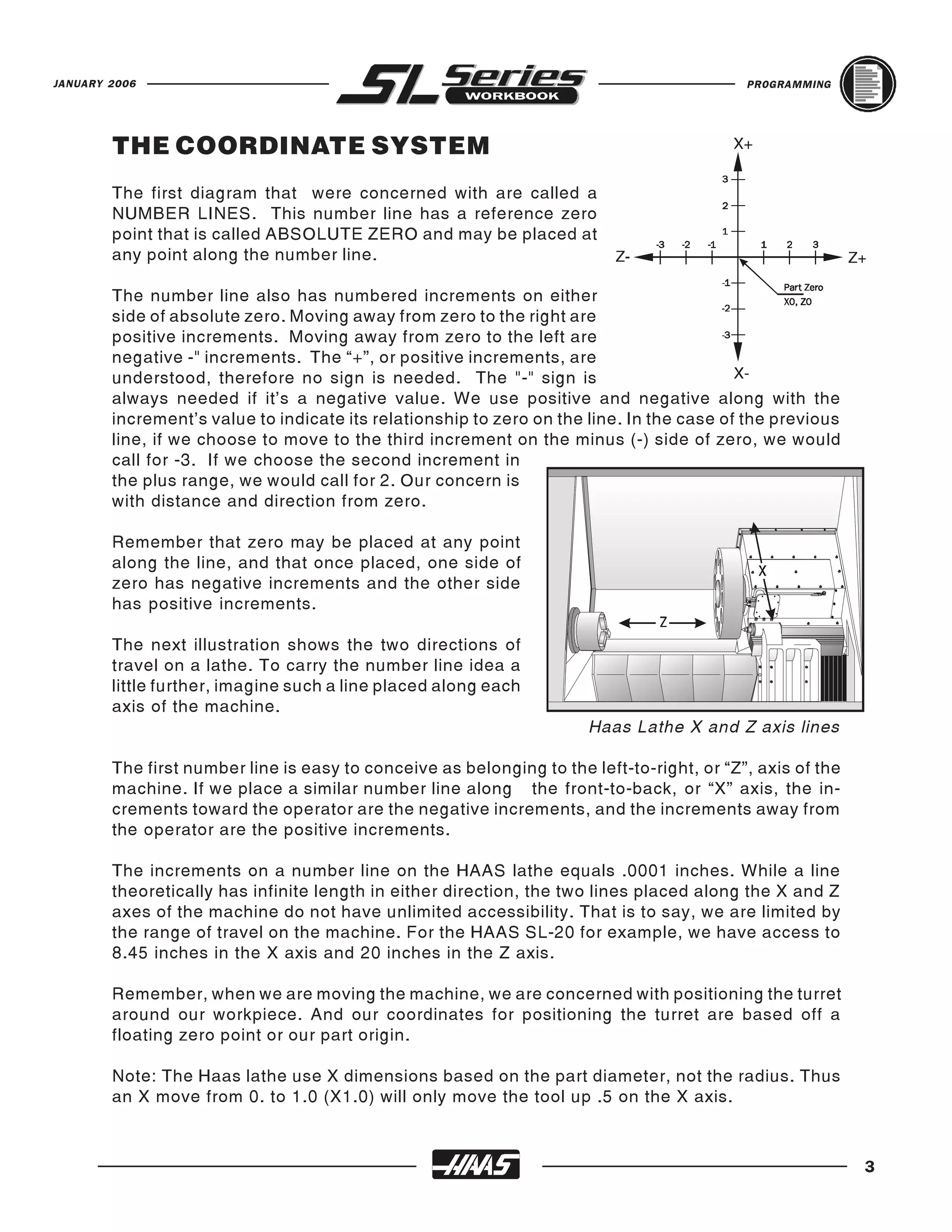

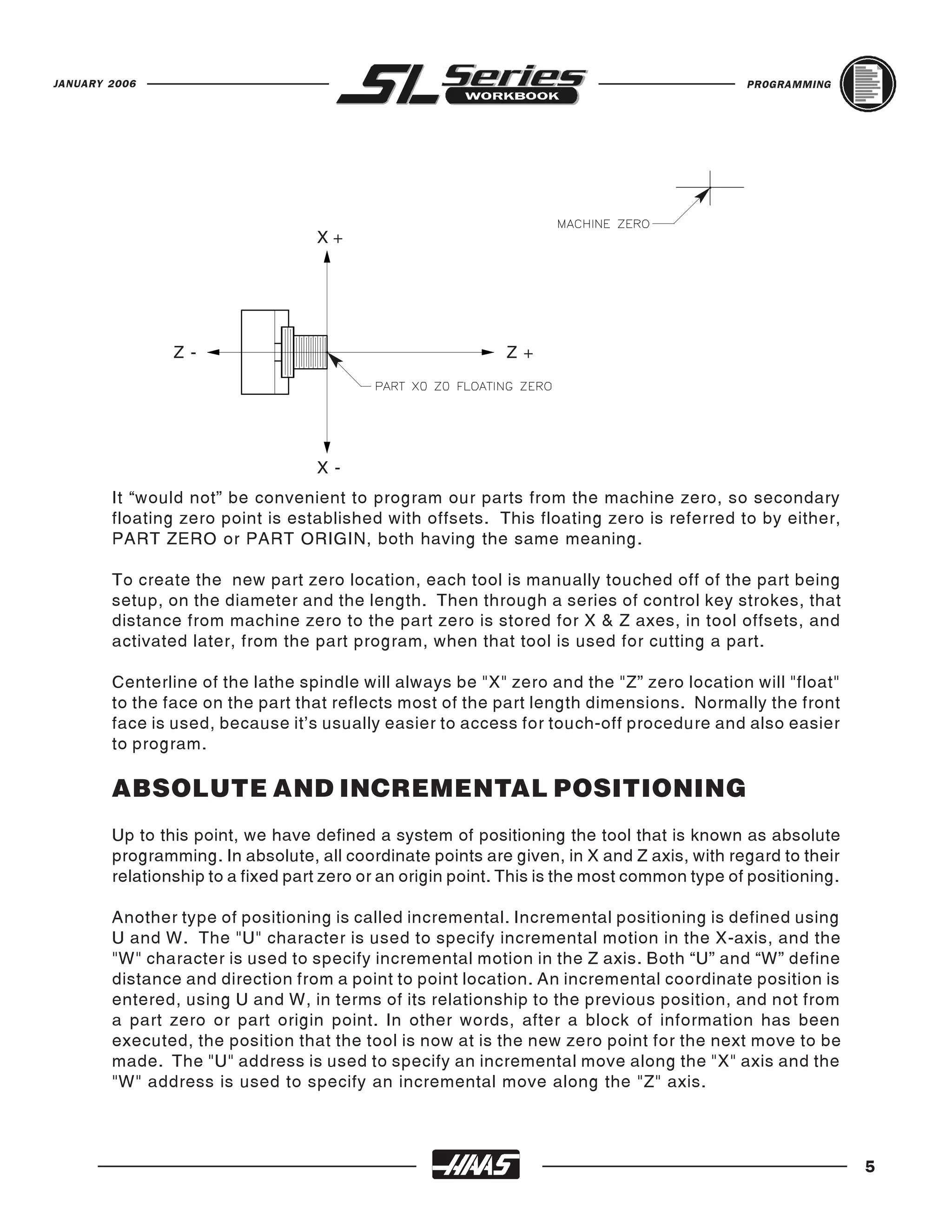

- The coordinate system consists of an X and Z axis.

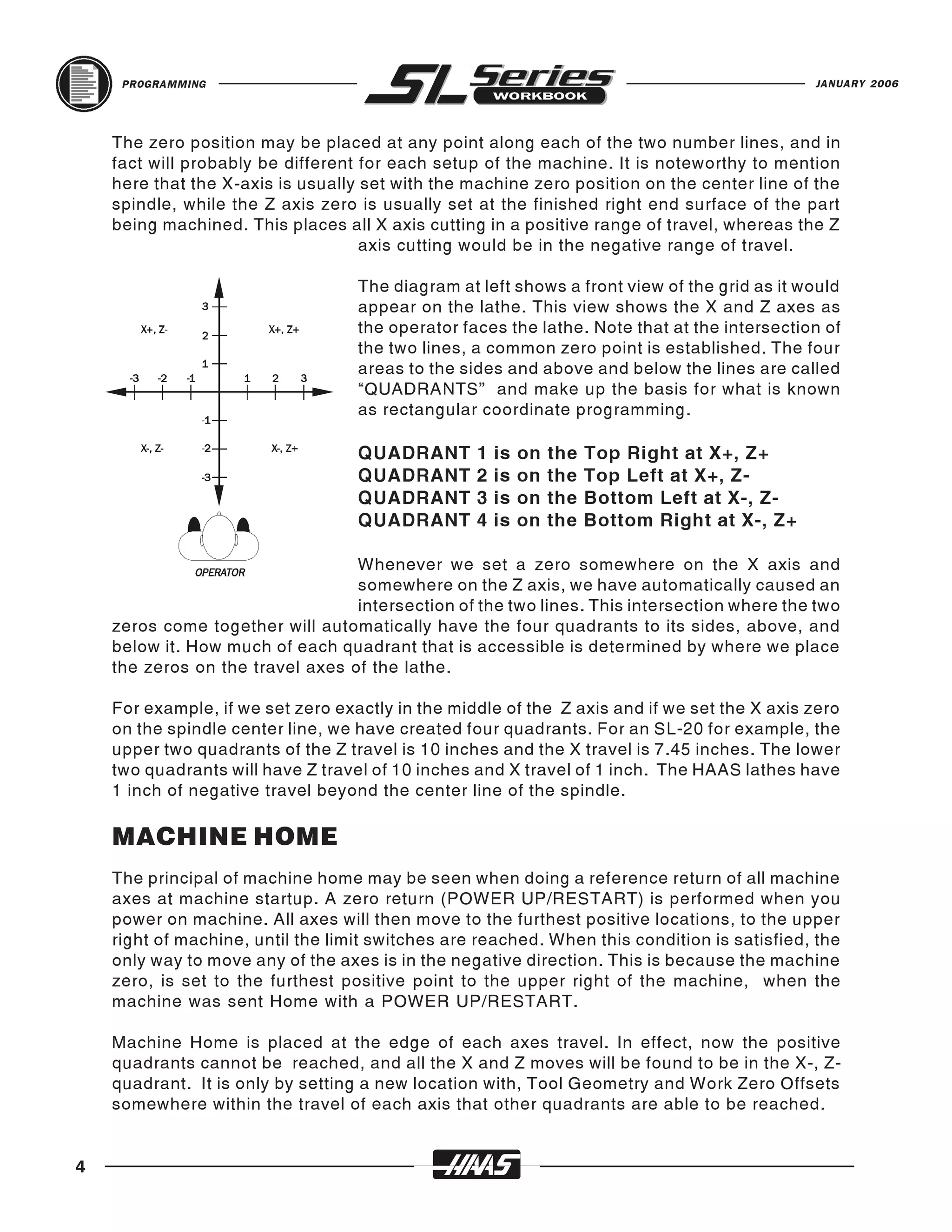

- The X axis represents movement parallel to the lathe bed and movement along the axis is called longitudinal or axial.

- The Z axis represents movement at right angles to the lathe bed and movement along this axis is called transverse or radial.

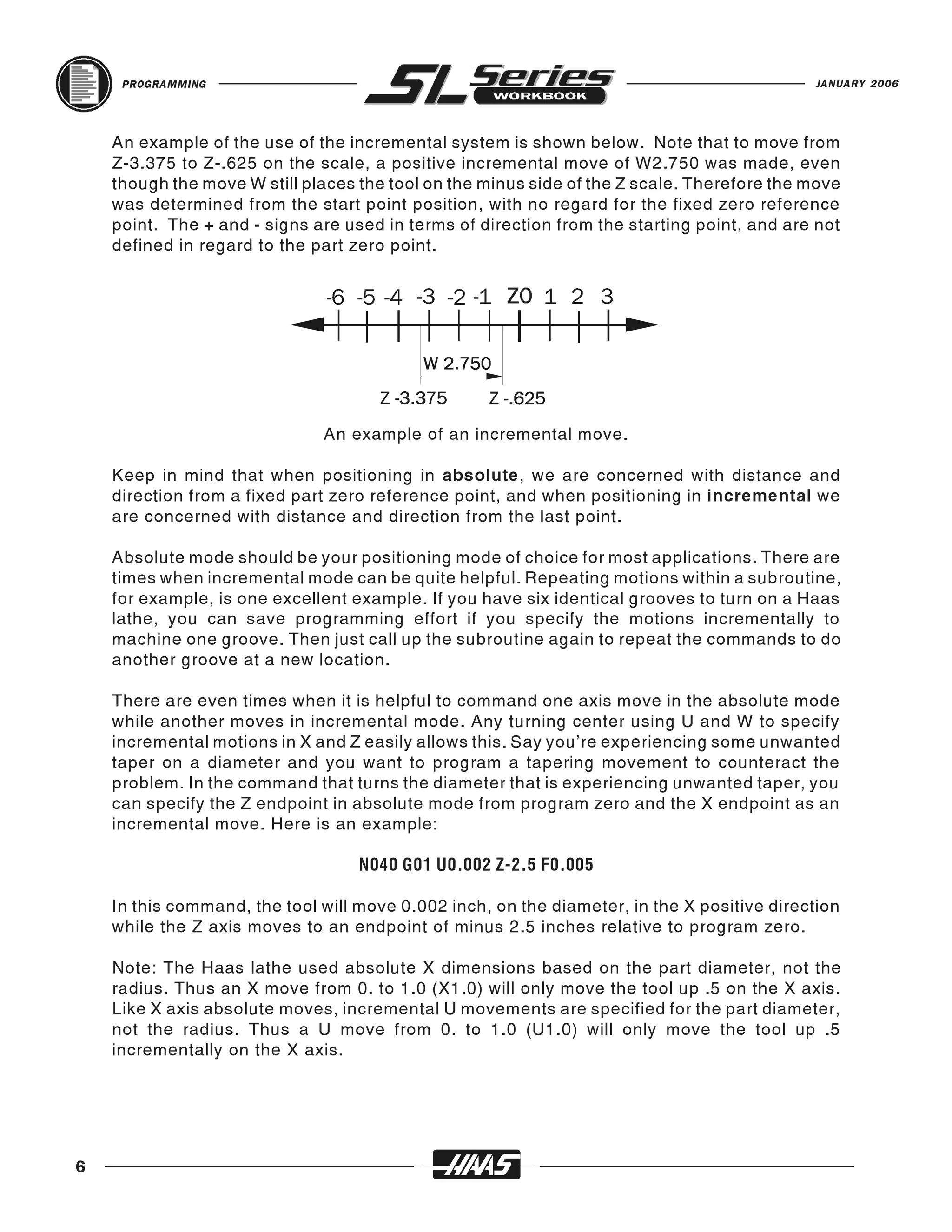

- Absolute zero is the reference point from which all positions are measured along each axis. Positions to the right of zero are positive and to the left are negative along the X axis, while above zero is positive and below is negative along the Z axis.