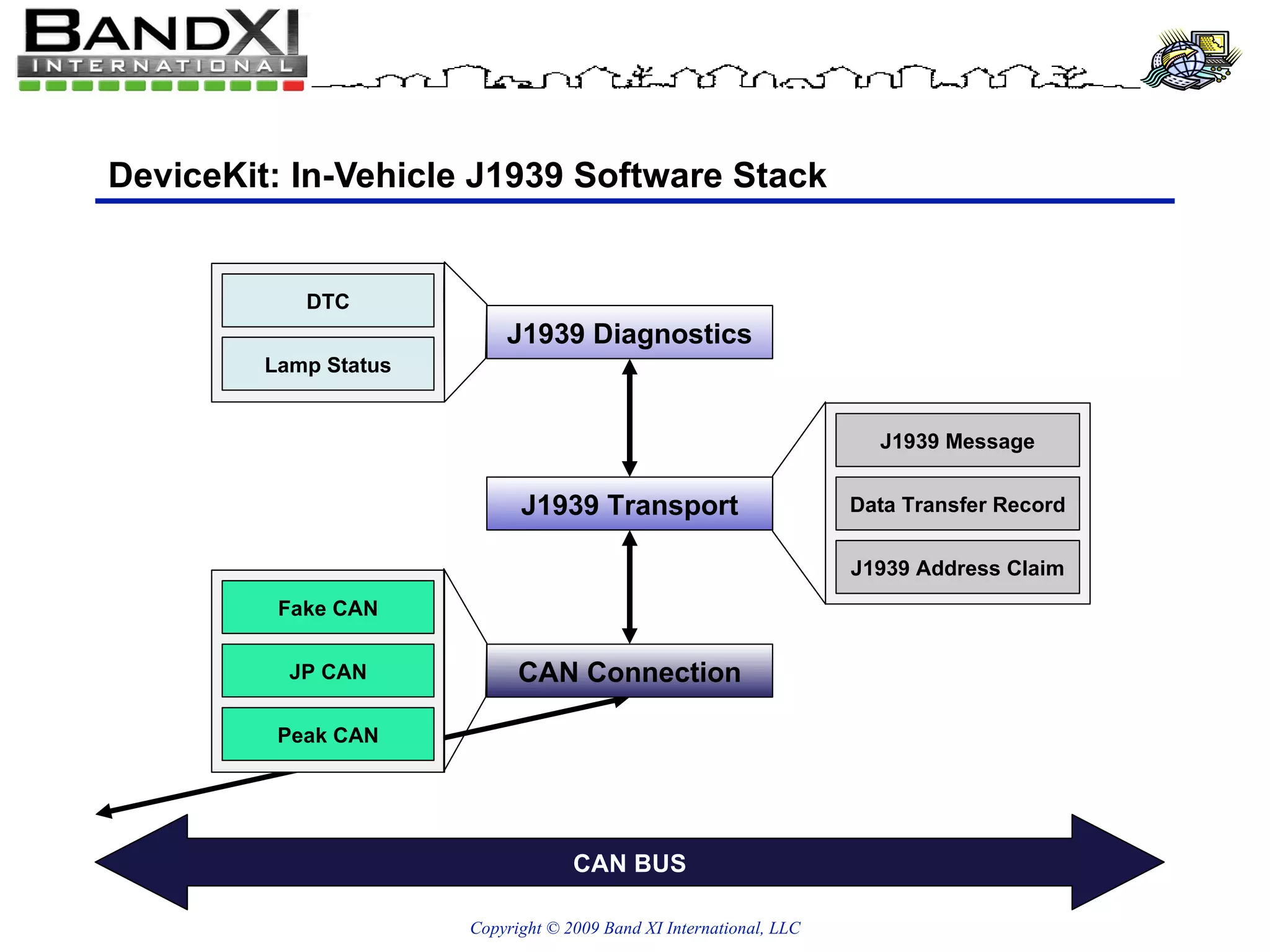

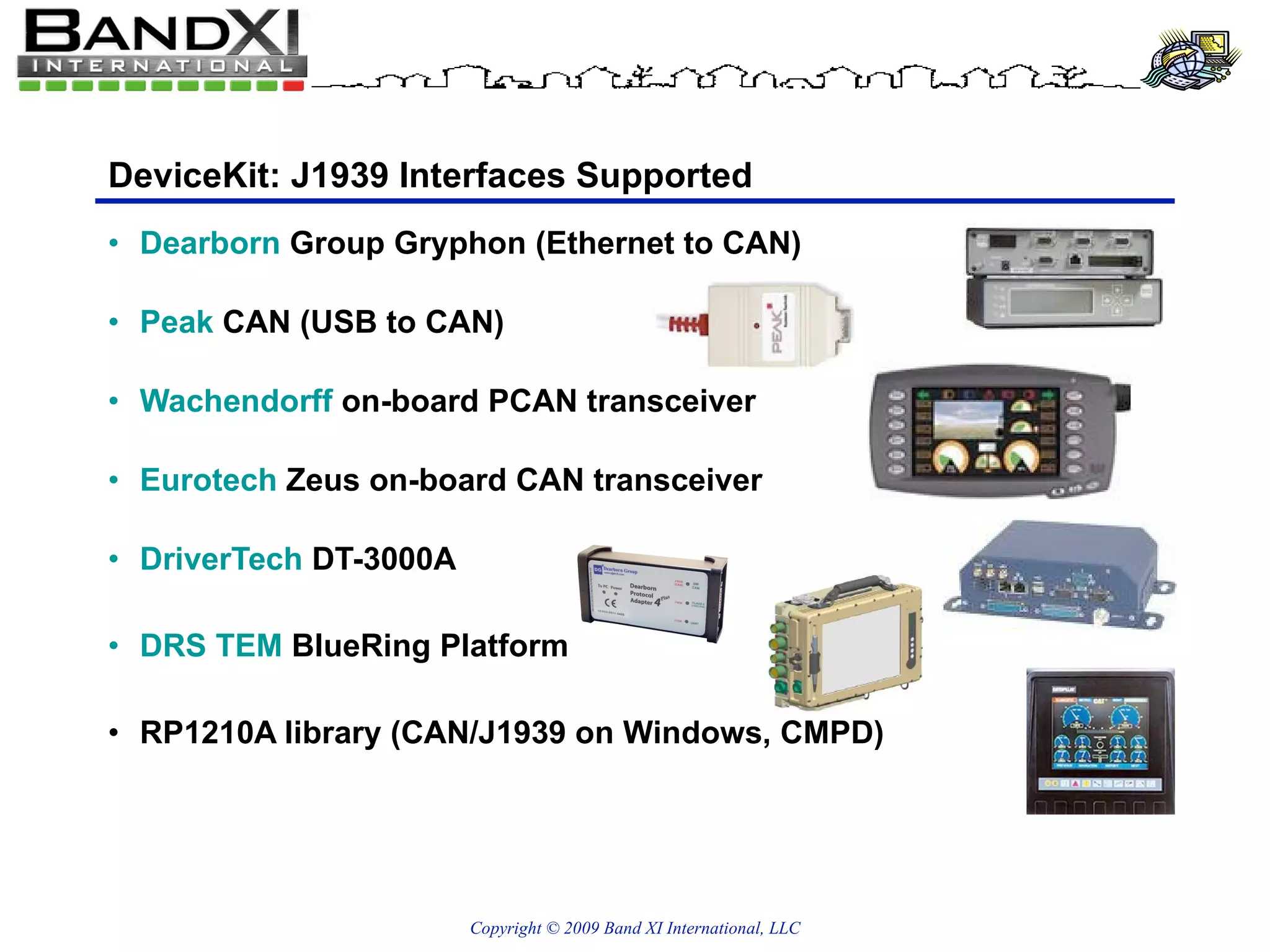

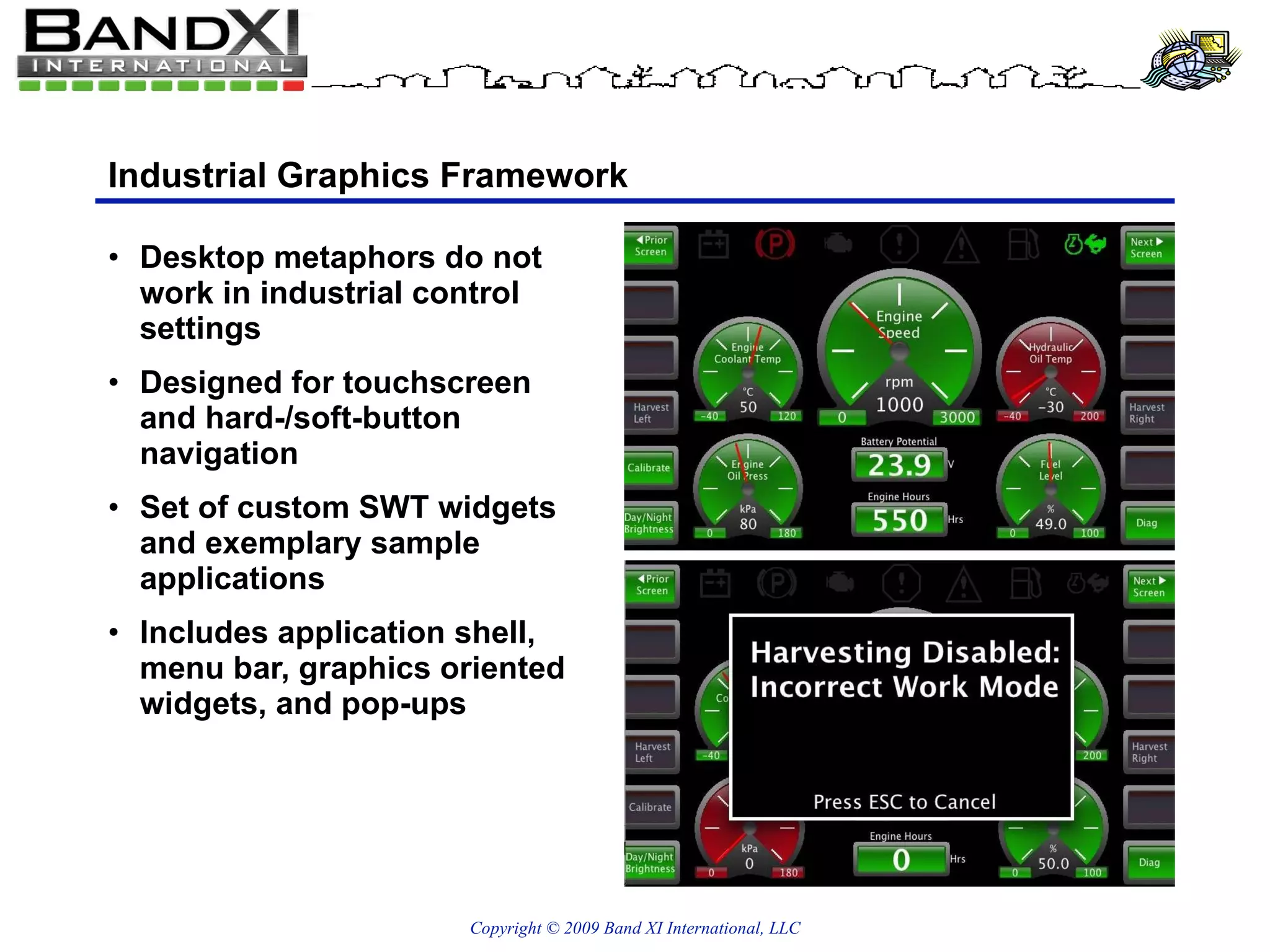

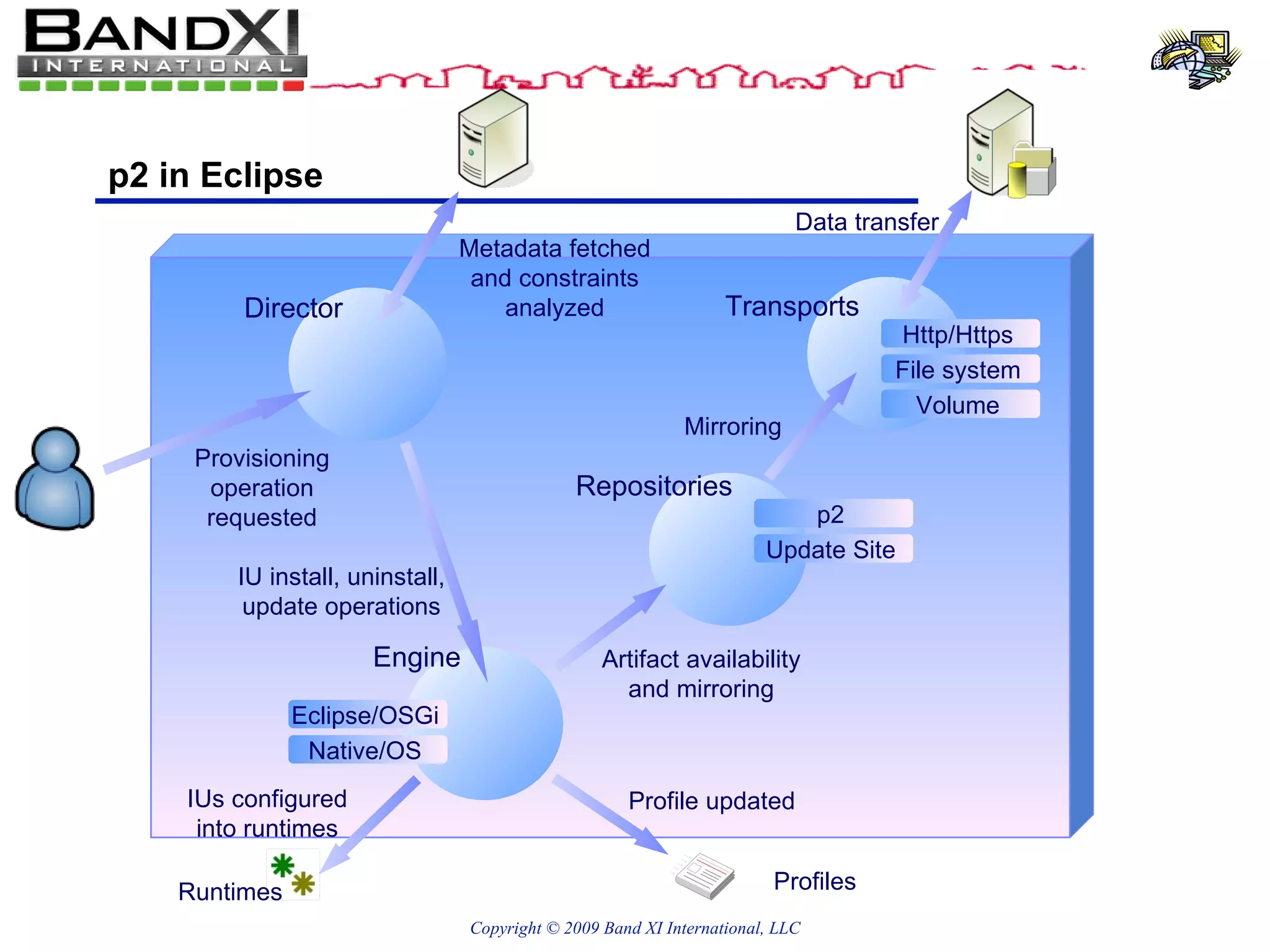

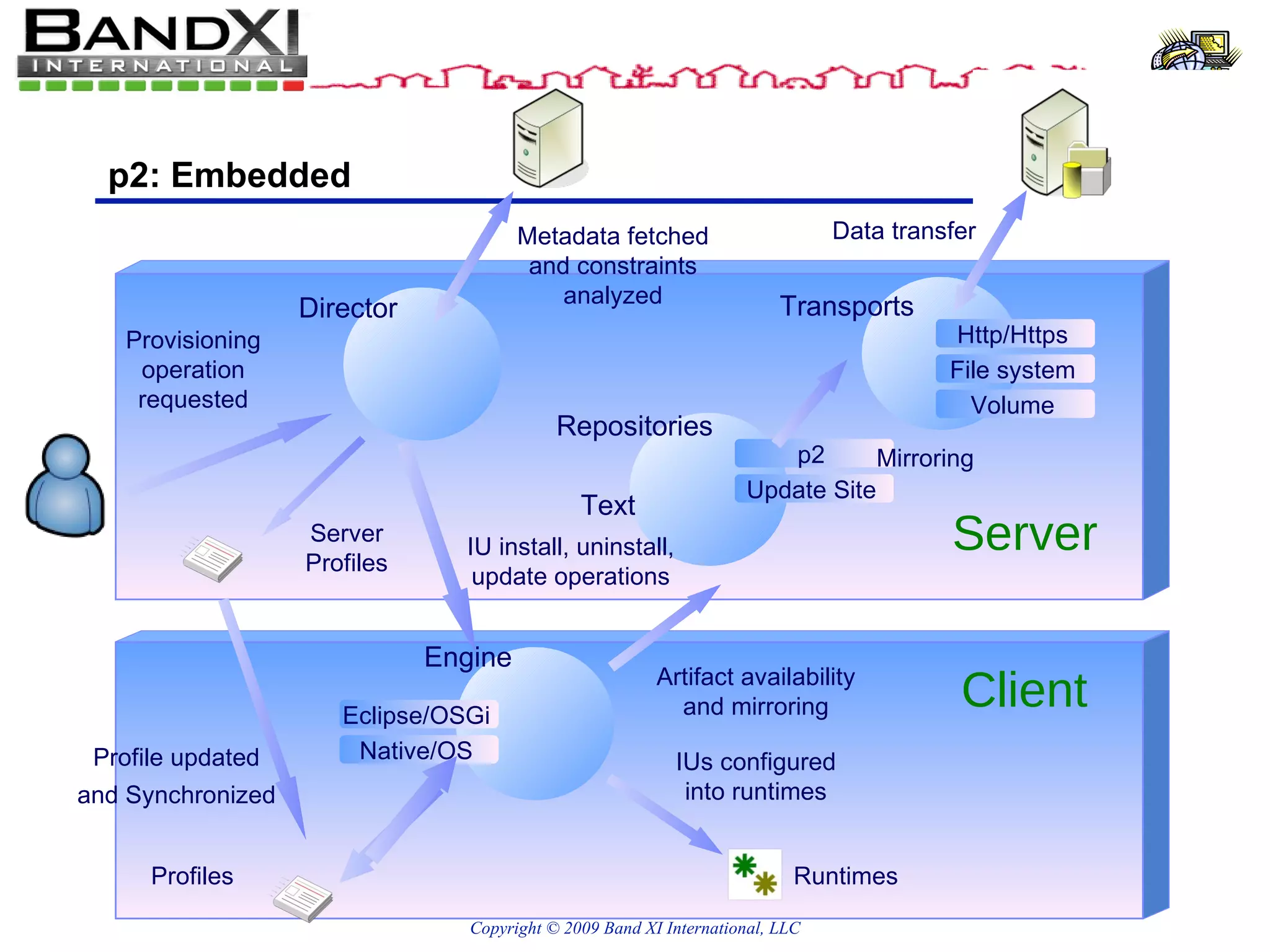

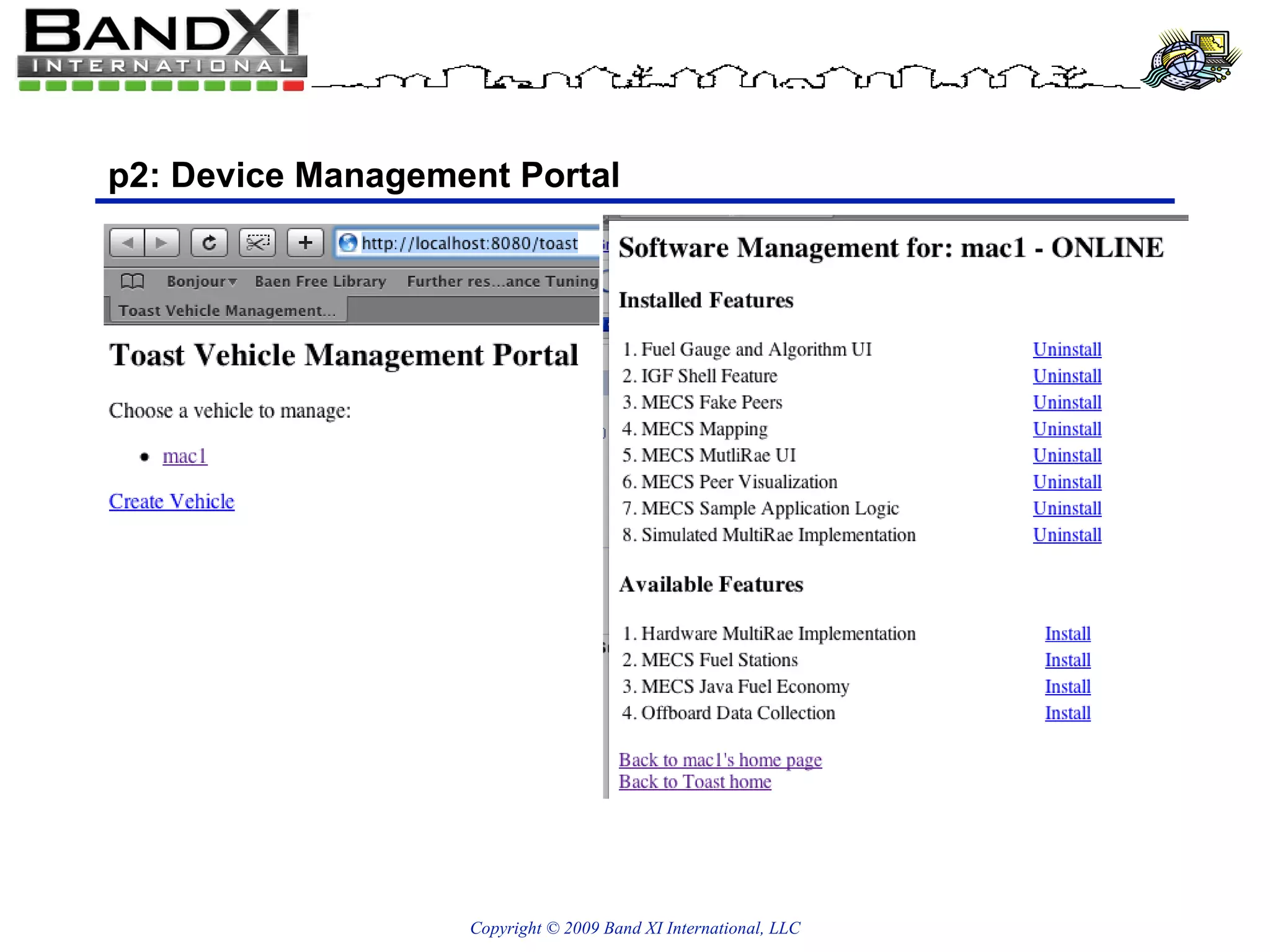

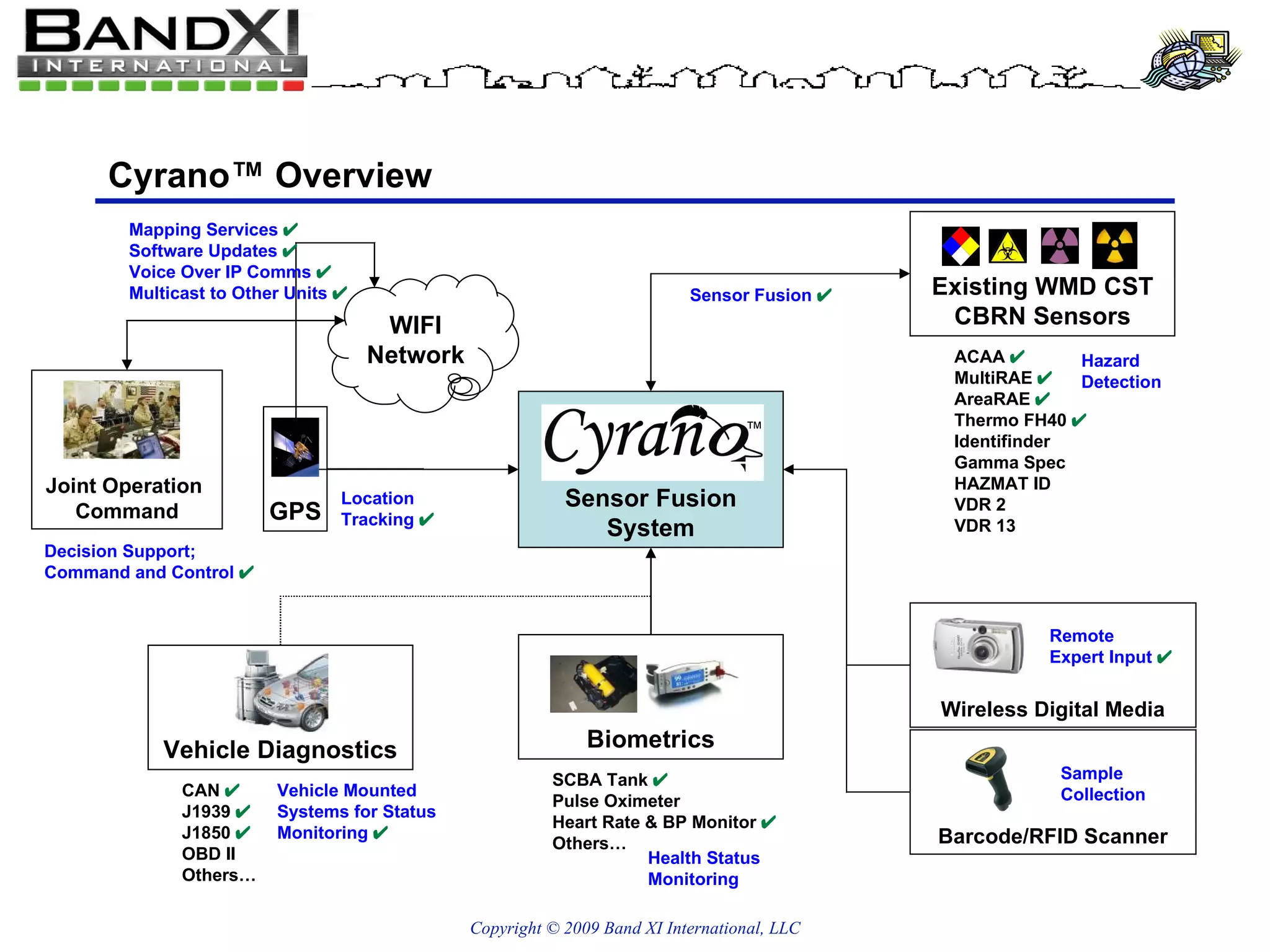

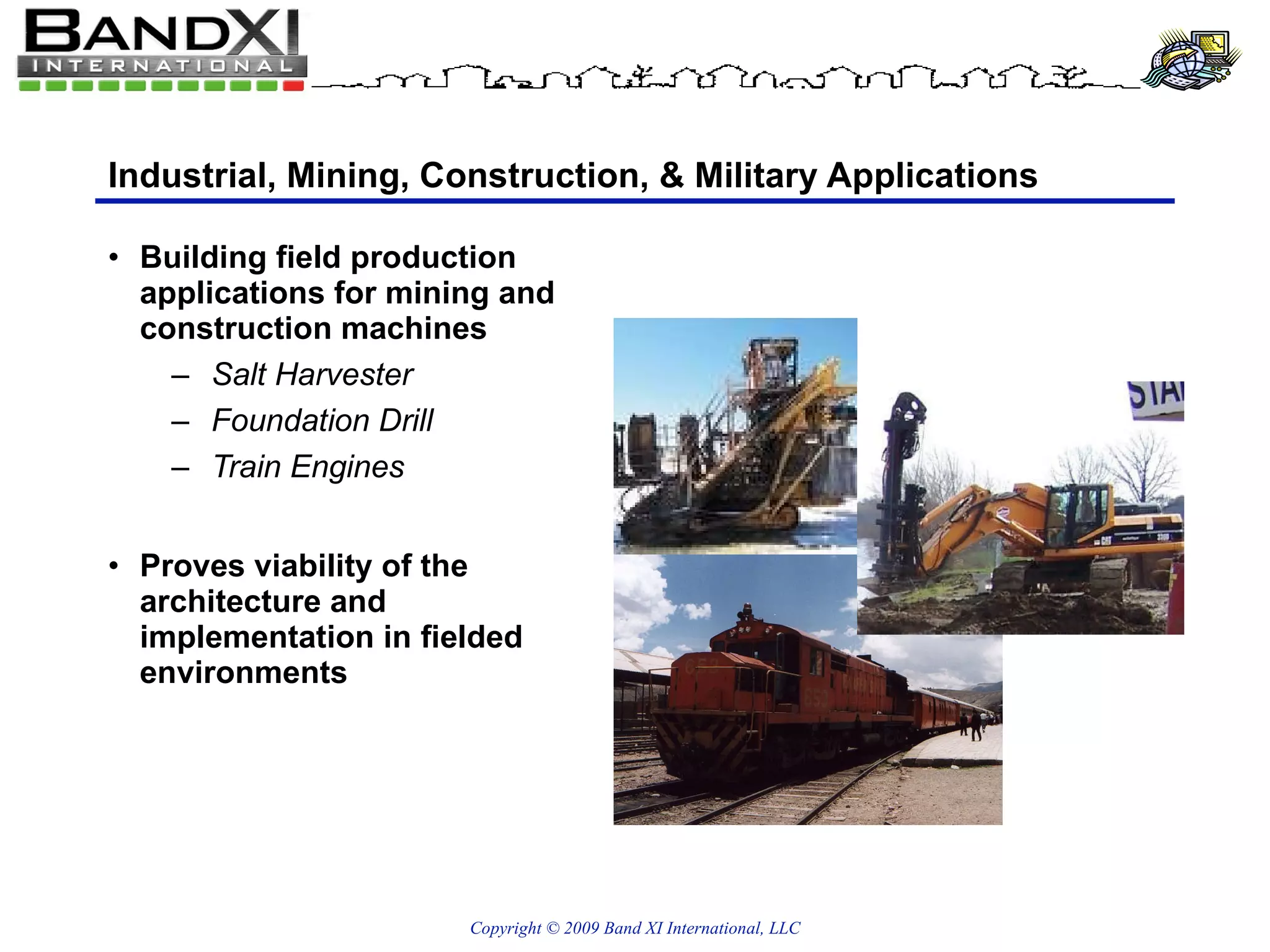

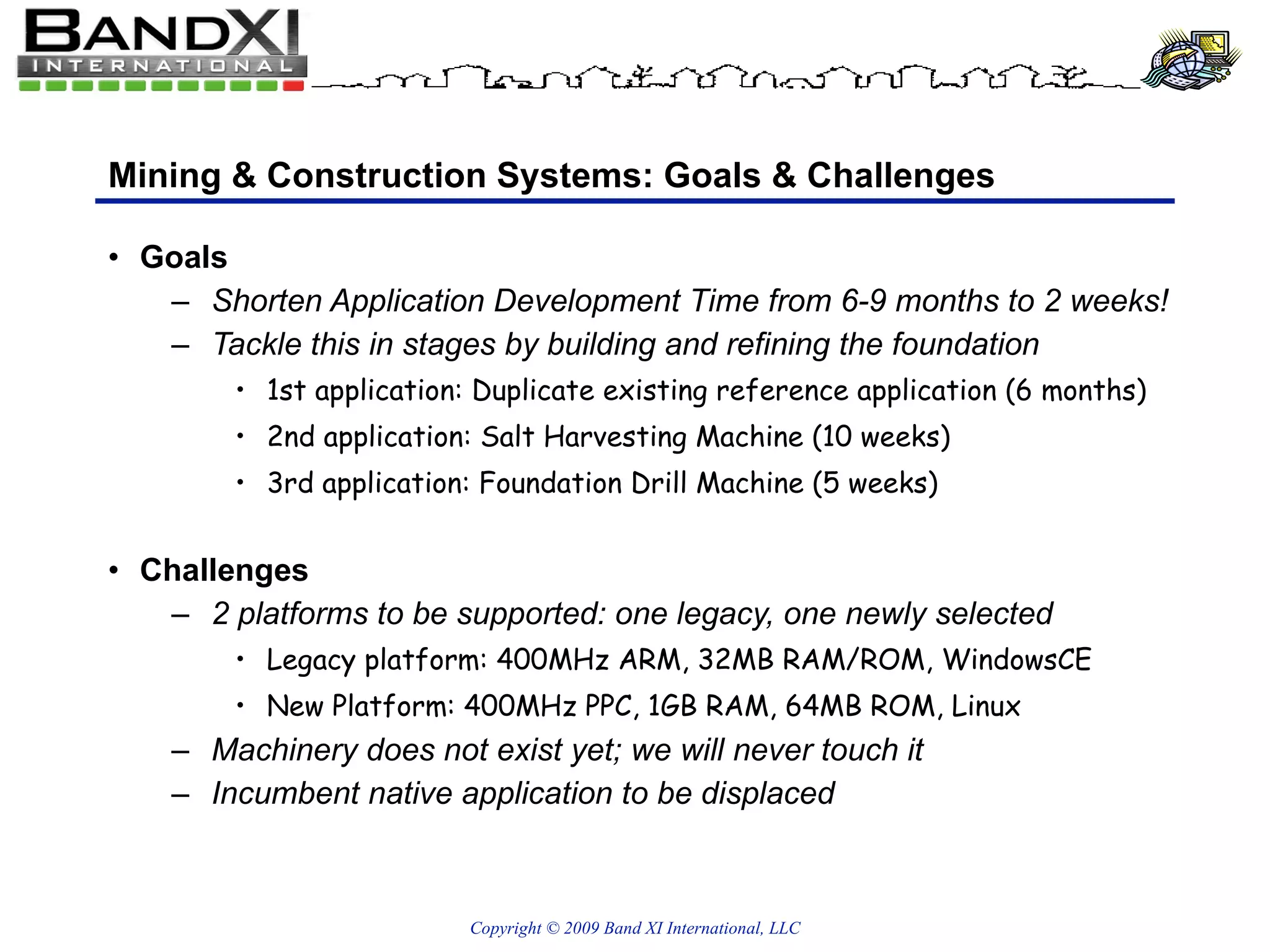

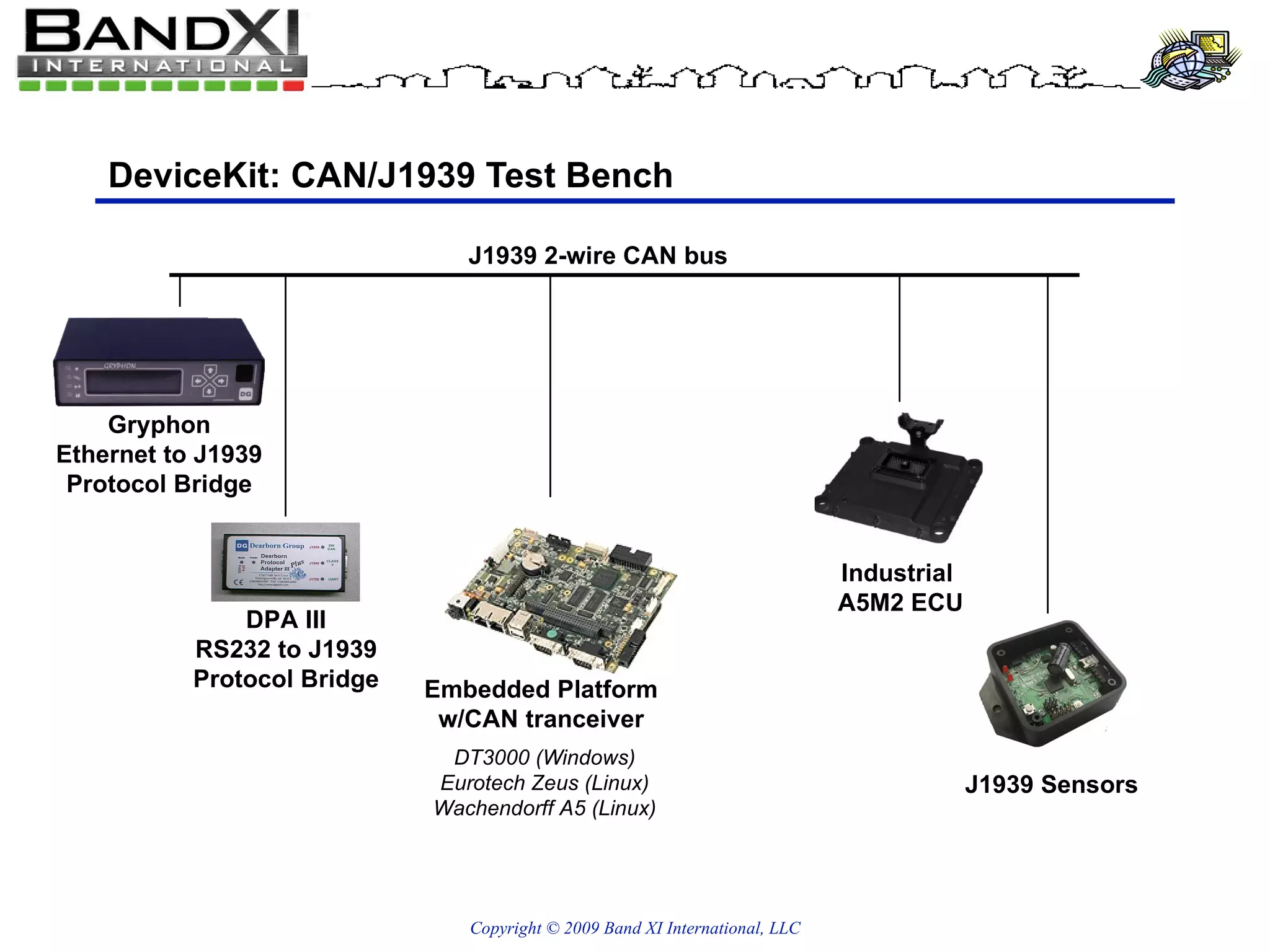

The document discusses using the Eclipse framework and OSGi for developing modular applications for embedded devices. It describes challenges in embedded systems development and how OSGi addresses these challenges through loose coupling and dynamic updating. It also summarizes several Eclipse projects - DeviceKit for hardware interfacing, an industrial graphics framework, and p2 for remote provisioning - and provides examples of applications developed with these technologies, including for the US Army.