SET-UP

- 2. Developed in Japan in the 1950, the first person to use that term as a tool to reduce the time to change toolings in production lines was Shingeo Shingo. History Paulo D. Oliveira

- 3. • 1950 – Mazda (Japan) • 1957 – Mitsubishi (Japan) • 1969 – Toyota (Japan) Evolution Paulo D. Oliveira

- 4. The need The presses were major bottlenecks of production because the operators were waiting the work of the press, while several activities could be carried out during this idle time presses were in operation, then the internal and external set-up emerged. Paulo D. Oliveira

- 5. The transformation The router used in the machining of diesel engines did not operate at full capacity, then it was the bottleneck of production, and some tasks and operations could be made in production during the operation of the router, so it was necessary to transform the internal in external set-up. Paulo D. Oliveira

- 6. The deployment The Volkwagen was the company that imported and implemented the concept of set-up on your plants and managed to ensure efficiency in their processes at the same time that Toyota still analyzing the need for reducing time on tool changes, already thinking about continuous improvement . Paulo D. Oliveira

- 7. The modernization With the need to reduce time on tool changes, this time it was 4 hours and should be halved as required by management, with much analysis, that time dropped to 90 minutes and after 3 months of hard work, was can perform tool changes in less than 10 minutes. Paulo D. Oliveira

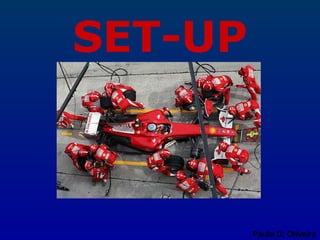

- 8. Other applications SPORTS ART SECURITY HEALTH Paulo D. Oliveira

- 9. The set-up is nothing more than a quick change of tools during the time of interruption of production operations until such time that operations can be continued again in execution since after the tool change. General concept Paulo D. Oliveira

- 10. The set-up should be classified as continuous improvement, therefore we can apply the set-up time reduction in their own set-up, and then we can just set new reduction targets and objectives to be achieved while maintaining full quality. Continuous improvement Paulo D. Oliveira

- 11. The time to set-up does not add any value to the company, to the contrary, means a non-productive time, time in which production is stopped and does not generate income, so there are concepts for reducing set-up time. Values Paulo D. Oliveira

- 12. Tool change Previous production Starting new production TOOL CHANGE OR SET-UP Paulo D. Oliveira

- 13. When the tools are neatly separated for use before you even disrupt production, call External Set-Up, in other words, everything is prepared without stopping the production line. External Set-up(Offline) Paulo D. Oliveira

- 14. When the production line is stopped for tool change, the set-up is performed on line, then the downtime occurs on the line, this set-up is called Internal Set-up. The set-up should be done quickly so that the production is not so delayed with respect to time. Internal Set-up (Online) Paulo D. Oliveira

- 15. The Set-Up is increasingly tied directly to production since it depends on time not to adversely affect the company's production capacity and consequently the delivery of its products within the regulated with your direct customer term. Paulo D. Oliveira

- 16. THANK YOU ! Paulo D. Oliveira