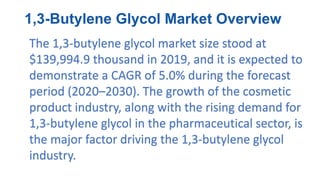

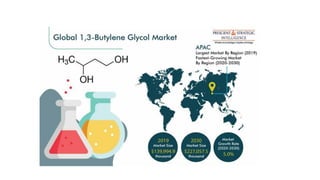

A bioengineering company produces Brontide butylene glycol from a sustainable fermentation process, supplying 600 tons to the European market. Unlike most butylene glycol sourced from petroleum, Brontide is made directly from plant-based sugars and certified as natural and bio-based. Its production has the potential to reduce greenhouse gases by 100,000 tons of CO2e per year and eliminate 50,000 tons of the carcinogen acetaldehyde used in conventional methods. The global 1,3-butylene glycol market is expected to grow at a 5% CAGR through 2030 due to rising demand from the cosmetics and pharmaceutical industries.