DYN-204.pdf

•

0 likes•2 views

Column Sensor | Cantilever Beam Load Cell | S-type Tension Pressure Sensor | Capsule Sensor | Tension Sensor | Multi Dimensional Force Sensor | Micro Sensor | Spoke Pressure Sensor | Weighing Module | Static Torque Sensor | Dynamic Torque Sensor | Diffused Silicon Pressure Transmitter | Weighing Junction Box | Weighing Transducer

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

Similar to DYN-204.pdf

Similar to DYN-204.pdf (20)

More from arco zhang

More from arco zhang (20)

Recently uploaded

CHEAP Call Girls in Vinay Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Vinay Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE9953056974 Low Rate Call Girls In Saket, Delhi NCR

Top Rated Pune Call Girls Ravet ⟟ 6297143586 ⟟ Call Me For Genuine Sex Servi...

Top Rated Pune Call Girls Ravet ⟟ 6297143586 ⟟ Call Me For Genuine Sex Servi...Call Girls in Nagpur High Profile

CHEAP Call Girls in Mayapuri (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Mayapuri (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE9953056974 Low Rate Call Girls In Saket, Delhi NCR

CHEAP Call Girls in Hauz Quazi (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Hauz Quazi (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE9953056974 Low Rate Call Girls In Saket, Delhi NCR

CHEAP Call Girls in Ashok Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Ashok Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE9953056974 Low Rate Call Girls In Saket, Delhi NCR

Recently uploaded (20)

CHEAP Call Girls in Vinay Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Vinay Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

Top Rated Pune Call Girls Ravet ⟟ 6297143586 ⟟ Call Me For Genuine Sex Servi...

Top Rated Pune Call Girls Ravet ⟟ 6297143586 ⟟ Call Me For Genuine Sex Servi...

CHEAP Call Girls in Mayapuri (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Mayapuri (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

Call Girls Banashankari Just Call 👗 7737669865 👗 Top Class Call Girl Service ...

Call Girls Banashankari Just Call 👗 7737669865 👗 Top Class Call Girl Service ...

CHEAP Call Girls in Hauz Quazi (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Hauz Quazi (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

Bommasandra Call Girls: 🍓 7737669865 🍓 High Profile Model Escorts | Bangalore...

Bommasandra Call Girls: 🍓 7737669865 🍓 High Profile Model Escorts | Bangalore...

Book Paid Lohegaon Call Girls Pune 8250192130Low Budget Full Independent High...

Book Paid Lohegaon Call Girls Pune 8250192130Low Budget Full Independent High...

Escorts Service Arekere ☎ 7737669865☎ Book Your One night Stand (Bangalore)

Escorts Service Arekere ☎ 7737669865☎ Book Your One night Stand (Bangalore)

➥🔝 7737669865 🔝▻ Deoghar Call-girls in Women Seeking Men 🔝Deoghar🔝 Escorts...

➥🔝 7737669865 🔝▻ Deoghar Call-girls in Women Seeking Men 🔝Deoghar🔝 Escorts...

9892124323 Pooja Nehwal Call Girls Services Call Girls service in Santacruz A...

9892124323 Pooja Nehwal Call Girls Services Call Girls service in Santacruz A...

Escorts Service Sanjay Nagar ☎ 7737669865☎ Book Your One night Stand (Bangalore)

Escorts Service Sanjay Nagar ☎ 7737669865☎ Book Your One night Stand (Bangalore)

Call Girls Kothrud Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Kothrud Call Me 7737669865 Budget Friendly No Advance Booking

➥🔝 7737669865 🔝▻ Vijayawada Call-girls in Women Seeking Men 🔝Vijayawada🔝 E...

➥🔝 7737669865 🔝▻ Vijayawada Call-girls in Women Seeking Men 🔝Vijayawada🔝 E...

Kothanur Call Girls Service: 🍓 7737669865 🍓 High Profile Model Escorts | Bang...

Kothanur Call Girls Service: 🍓 7737669865 🍓 High Profile Model Escorts | Bang...

CHEAP Call Girls in Ashok Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

CHEAP Call Girls in Ashok Nagar (-DELHI )🔝 9953056974🔝(=)/CALL GIRLS SERVICE

DYN-204.pdf

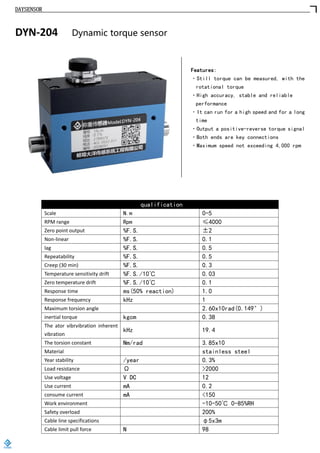

- 1. DAYSENSOR DYN-204 Dynamic torque sensor Features: ·Still torque can be measured, with the rotational torque ·High accuracy, stable and reliable performance ·It can run for a high speed and for a long time ·Output a positive-reverse torque signal ·Both ends are key connections ·Maximum speed not exceeding 4,000 rpm qualification Scale N.m 0-5 RPM range Rpm ≤4000 Zero point output %F.S. ±2 Non-linear %F.S. 0.1 lag %F.S. 0.5 Repeatability %F.S. 0.5 Creep (30 min) %F.S. 0.3 Temperature sensitivity drift %F.S./10℃ 0.03 Zero temperature drift %F.S./10℃ 0.1 Response time ms(50% reaction) 1.0 Response frequency kHz 1 Maximum torsion angle 2.60x10rad(0.149°) inertial torque kgcm 0.38 The ator vibrvibration inherent vibration kHz 19.4 The torsion constant Nm/rad 3.85x10 Material stainless steel Year stability /year 0.3% Load resistance Ω >2000 Use voltage V DC 12 Use current mA 0.2 consume current mA <150 Work environment -10-50℃ 0-85%RH Safety overload 200% Cable line specifications φ5x3m Cable limit pull force N 98 https://www.loadcells.store

- 2. DAYSENSOR 1) High temperature sensors are available, with a maximum operating temperature of 150℃. 2) High impedance sensors can be provided with an output impedance of 1000 Ω. Product Size Fig Unit: mm force diagram Range(N.m) 0.1 0.2 0.3 0.5 1 2 3 5 Load device | Coupling | Sensor | servo motor Fixed installation on both sides