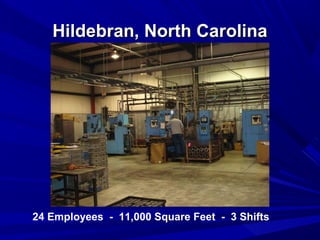

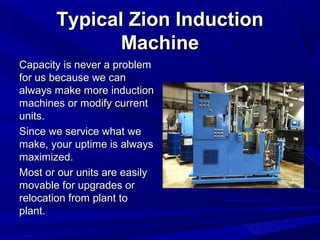

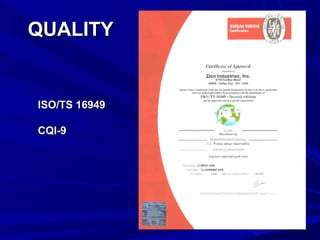

Zion Industries provides precision induction heat treating services across three locations in Ohio, Michigan, and North Carolina. They have over 70 employees and specialize in induction hardening, annealing, brazing, tempering, and related quality services. Zion is a leader in the induction heat treating industry since 1977, known for high quality services and self-sufficient equipment manufacturing to maximize customers' efficiency and uptime.