White Bag Brochure

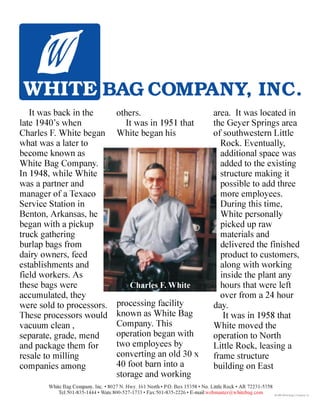

- 1. It was back in the

late 1940’s when

Charles F. White began

what was a later to

become known as

White Bag Company.

In 1948, while White

was a partner and

manager of a Texaco

Service Station in

Benton, Arkansas, he

began with a pickup

truck gathering

burlap bags from

dairy owners, feed

establishments and

field workers. As

these bags were

accumulated, they

were sold to processors.

These processors would

vacuum clean ,

separate, grade, mend

and package them for

resale to milling

companies among

others.

It was in 1951 that

White began his

processing facility

known as White Bag

Company. This

operation began with

two employees by

converting an old 30 x

40 foot barn into a

storage and working

area. It was located in

the Geyer Springs area

of southwestern Little

Rock. Eventually,

additional space was

added to the existing

structure making it

possible to add three

more employees.

During this time,

White personally

picked up raw

materials and

delivered the finished

product to customers,

along with working

inside the plant any

hours that were left

over from a 24 hour

day.

It was in 1958 that

White moved the

operation to North

Little Rock, leasing a

frame structure

building on East

Charles F. White

White Bag Company, Inc. • 8027 N. Hwy. 161 North • P.O. Box 15358 • No. Little Rock • AR 72231-5358

Tel:501-835-1444 • Wats:800-527-1733 • Fax:501-835-2226 • E-mail:webmaster@whitebag.com

BAG COMPANY, INC.

©1998 White Bag Company, Inc.

- 2. Washington Avenue.

This expansion allowed

for more employees

and equipment to be

brought into action.

The increase in

productivity

quickly overtook

the price of the

expansion and

overhead. A full

service bag

closing shop was

added to the

operation for the

repairing and

selling of bag

closing

equipment to the

feed milling

establishments.

This growth

caused the

business to be

incorporated in 1962 as

White Bag Company,

Inc.

In 1964, fire

destroyed the entire

operation. This caused

the company to relocate

in Jacksonville,

Arkansas. Acquiring

30,000 square feet of

industrial/warehouse

space, White Bag

Company began its

transition to

becoming a very

competitive

manufacturing

corporation. By 1972,

Charles White had

introduced two new

lines of manufactured

textile bags, burlap and

woven polypropylene.

Burlap is a natural

fabric produced

from jute, which is

imported mainly

from Bangladesh

and Calcutta. Woven

polypropylene is a

synthetic fiber

produced from

byproducts of the

petroleum industry.

This product came

in the early seventies

as a domestic

product, later to be

produced mainly by

foreign countries.

White Bag Company, Inc. • 8027 N. Hwy. 161 North • P.O. Box 15358 • No. Little Rock • AR 72231-5358

Tel:501-835-1444 • Wats:800-527-1733 • Fax:501-835-2226 • E-mail:webmaster@whitebag.com

WHITEWHITE

BAG

COMPANY, INC.

©1998 White Bag Company, Inc.

Danny White

- 3. Historically, the burlap bag was mainly used as a 100 pound container, as

was woven polypropylene when it first came into existence. There has been

a transition to 50 pound containers beginning in the mid 1970s, with paper

taking the lead. Burlap being a natural fabric, even though considerably

higher in cost, has maintained a position in the market place for certain

applications. Polypropylene, unlike burlap, is a

synthetic material produced worldwide by the

petroleum industry. It is now being produced

and manufactured into a finished item by many

foreign countries. This lead White Bag

Company to become a distributor and broker of

these items, cutting costs and further establishing

its position as a very competitive bag company

for its clients. The leading sales item for White

Bag Company would be paper, with woven

polypropylene coming in a close second.

In 1994 the company purchased a building with

over 42,000 square feet, located at 8027 Highway 161 North in North Little

Rock. This well-kept facility is a modern industrial

complex that distributes more than 30 million bags

annually. This beautiful office and production

facility is the workplace of White Bag Company’s

employees, the finest and hardest working team of

skilled labor found in Arkansas.

White overlooks and assists his

son, Danny, President of White

Bag Company, with day to day

operations. Mary Penny, who’s

beginning with White Bag

Company dates back to 1977, is

White Bag Company, Inc. • 8027 N. Hwy. 161 North • P.O. Box 15358 • No. Little Rock • AR 72231-5358

Tel:501-835-1444 • Wats:800-527-1733 • Fax:501-835-2226 • E-mail:webmaster@whitebag.com

WHITEWHITE

BAG

COMPANY, INC.

©1998 White Bag Company, Inc.

- 4. Director of Operations.

The efficient manner of bag manufacturing developed by White Bag

Company has allowed it to become one of the

most competitive companies within its field in the

nation. Consequently, products of White Bag

Company are marketed and distributed to

customers nationwide. Product lines include multi-

wall paper bags, woven polypropylene bags,

burlap, cotton and open mesh bags. Bag closing

equipment and thread, parts and service for bag

closing equipment are provided by White Bag

Company.

Customers include the agricultural industries'

feed and seed producers, industrial products, and

custom manufacturing for applications designed

by White Bag Company's network of producers, distributors, and dealers.

Not only is White a great executive, but a great cattle rancher. White and

his grandson, Chris, have produced many champions, just like the staff at

White Bag Company. Chris, who has a degree in business/agriculture, has

worked with cattle from the

cradle to present time.

Flying W Ranch is

recognized for the

production of quality

Brahman cattle and Fl cattle,

using Brahmans and

Herefords. White has always

been a great supporter and

promoter of Arkansas cattle

ranchers.

White Bag Company, Inc. • 8027 N. Hwy. 161 North • P.O. Box 15358 • No. Little Rock • AR 72231-5358

Tel:501-835-1444 • Wats:800-527-1733 • Fax:501-835-2226 • E-mail:webmaster@whitebag.com

©1998 White Bag Company, Inc.

WHITEWHITE

BAG

COMPANY, INC.

- 5. Custom or Reproduced Artwork

Special Bags and Bag Closing Equipment

Custom Designed Bagging Products

http://www.whitebag.com

White Bag Company now provides artwork for its clients to ensure quick, reliable

service. Whether your design incorporates color or black and white photographs or

graphics, White Bag Company can reproduce it. White Bag Company can accept clients'

previously produced artwork, digital or not. White Bag supports CorelDraw 8, the leading

graphics package on the IBM PC platform. White Bag Company

also supports Adobe Illustrator, Adobe PageMaker, Macromedia

Freehand, and Quark Express.

It has never been easier to place orders for custom bags.

Customers may merely sketch a layout for their bags and provide a

written statement of details. Original photographs are also a great

help in the design and layout of bags.

White Bag Company is a manufacturer and distributor of multi-wall paper, burlap, woven,

polypropylene, cotton and a smaller line of polypropylene mesh and polyethylene bags.

Even though we are a custom bag manufacturer, we do carry a relatively large inventory

on all widely used sizes in plain stock items. Since we

manufacture custom bags, each bag is designed to meet each

customers' request, serving the feed, seed and industrial

trade.

We carry Fishbein and Union Special bag closing

equipment and a full line of parts, accessories, repairs and

thread...Our special blend Unisac and Pro-Co thread is the

best bag closing thread available today.We are anxious to

serve you with our products and welcome the opportunity to

supply your needs.

Concerning pricing, we quote delivered prices to your

destination because of the freight savings we can pass to our

customer. We welcome the opportunity to be of service.

White Bag Company can help you engineer custom designed bagging products. This

will keep White Bag Company very competitive with other manufacturers. By using well-

trained and hard-working employees, we will offset any serious competition with foreign

manufacturers north or south of the United States. This includes domestic bagging

manufacturers.

White Bag Company wants to be your partner. Let us help with the marketing of your

products and produce bagging products. For more information about how

White Bag Company can help your company, call Customer Service at or

use our Online Information Request Form at:

superior

1-800-835-2226

White Bag Company, Inc. • 8027 N. Hwy. 161 North • P.O. Box 15358 • No. Little Rock • AR 72231-5358

Tel:501-835-1444 • Wats:800-527-1733 • Fax:501-835-2226 • E-mail:webmaster@whitebag.com

©1998 White Bag Company, Inc.

WHITEWHITE

BAG

COMPANY, INC.

- 6. Modern Manufacturing Facility

White Bag Graphics DepartmentWhite Bag Company's Front Lobby

Welcome to White Bag's spacious bag production facility.

Expansive On-site Warehouse

White Bag Company, Inc.

8027 Hwy. 161 North

North Little Rock, AR 72231-5358

Tel: (501) 835-1444 • Wats: (800) 527-1733 Fax: (501) 835-2226•

E-mail: webmaster@whitebag.com ©1998 White Bag Company, Inc.

WHITEWHITE

BAG

COMPANY, INC.