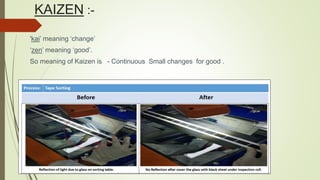

Poke yoke is a Japanese term for mistake-proofing processes to prevent inadvertent errors, exemplified by sensor mechanisms that stop production lines or alert operators to potential hazards. Kaizen refers to the philosophy of continuous improvement through small changes, while ECN (Engineering Change Note) is a procedure managed by the R&D department to implement vendor-requested changes in raw materials for cost savings. The ECN process involves verifying product reliability and dimensions before approval and communication with internal teams.