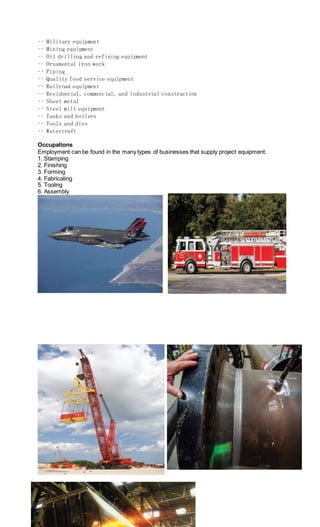

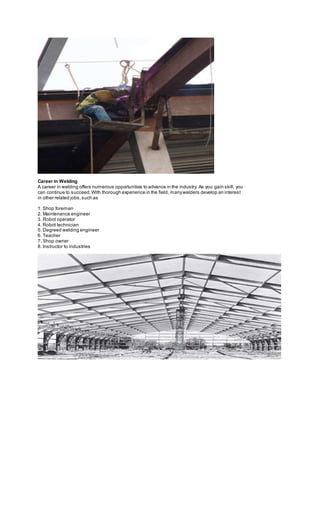

Welding involves fusing two or more pieces of metal together using heat from an electric arc welding machine. Welding has contributed to raising standards of living by enabling industries like renewable energy and space exploration. It is commonly used for fastening metal parts as it allows for durable, attractive, and safe construction. There are over 90 welding processes in use today across many industries like shipbuilding, aerospace, and energy. Welding is important to economic welfare as many industries rely on it for fabrication and repair of metal products. Welding offers employment opportunities worldwide and potential for career advancement into supervisory or technical roles.