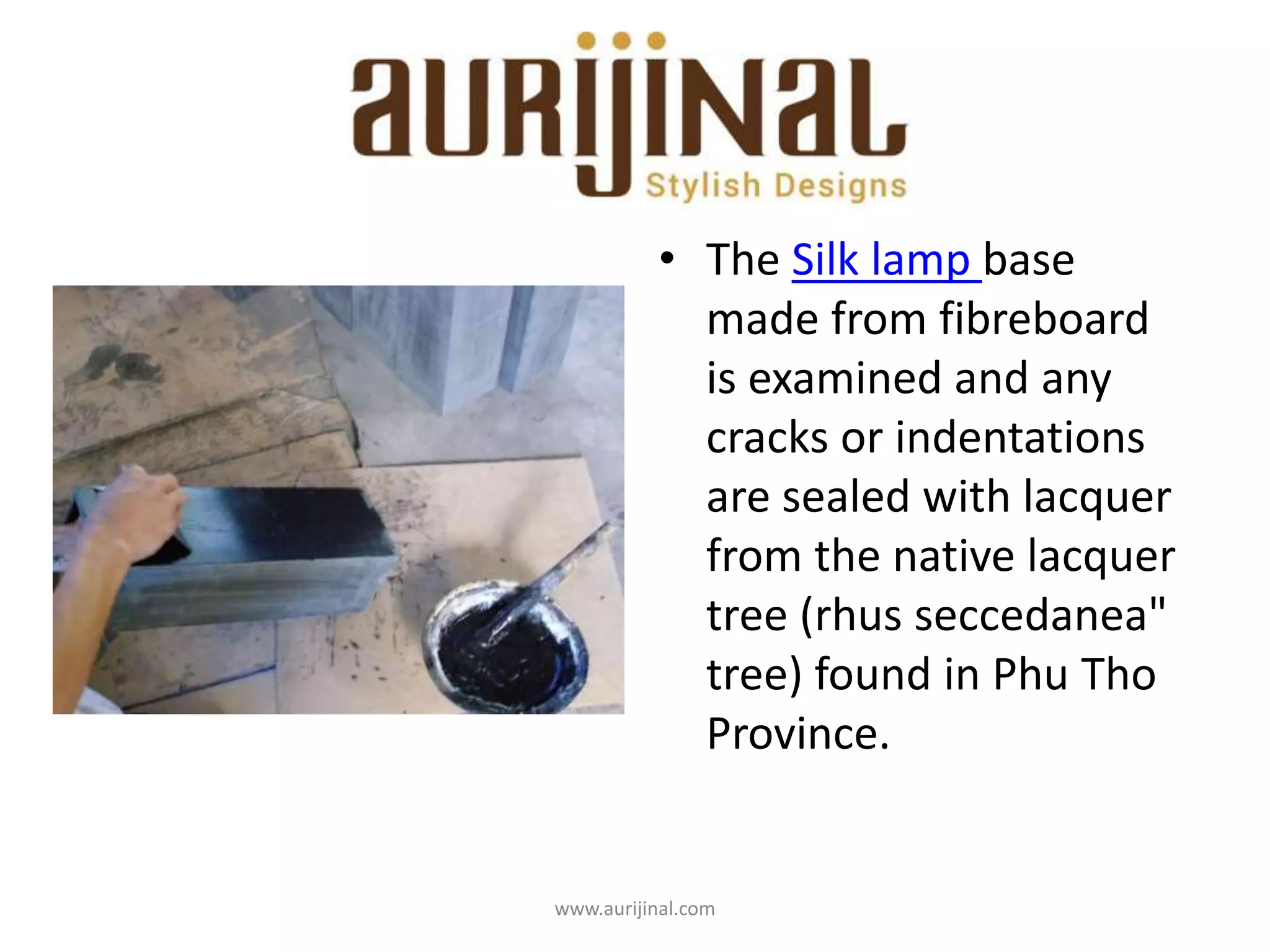

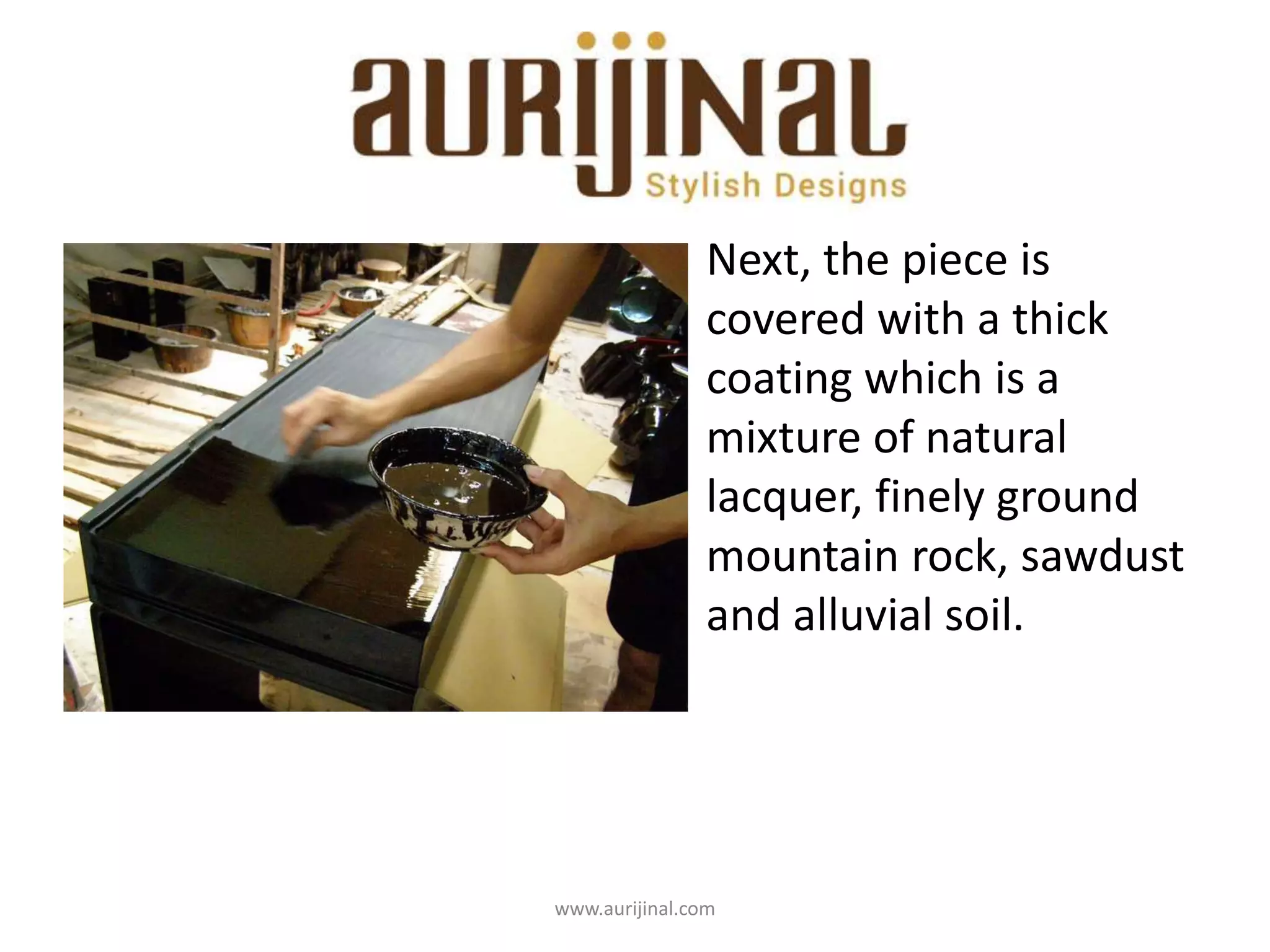

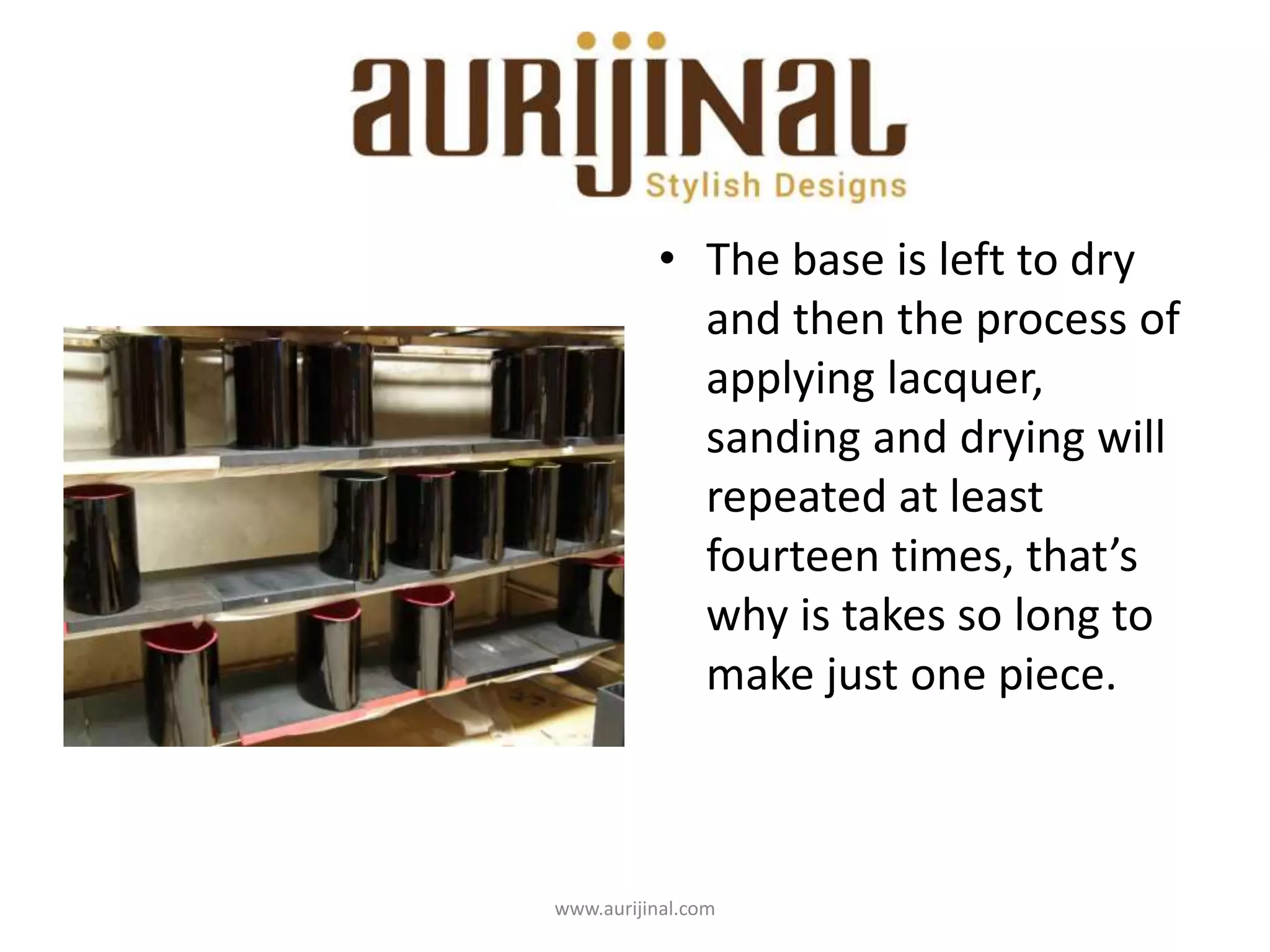

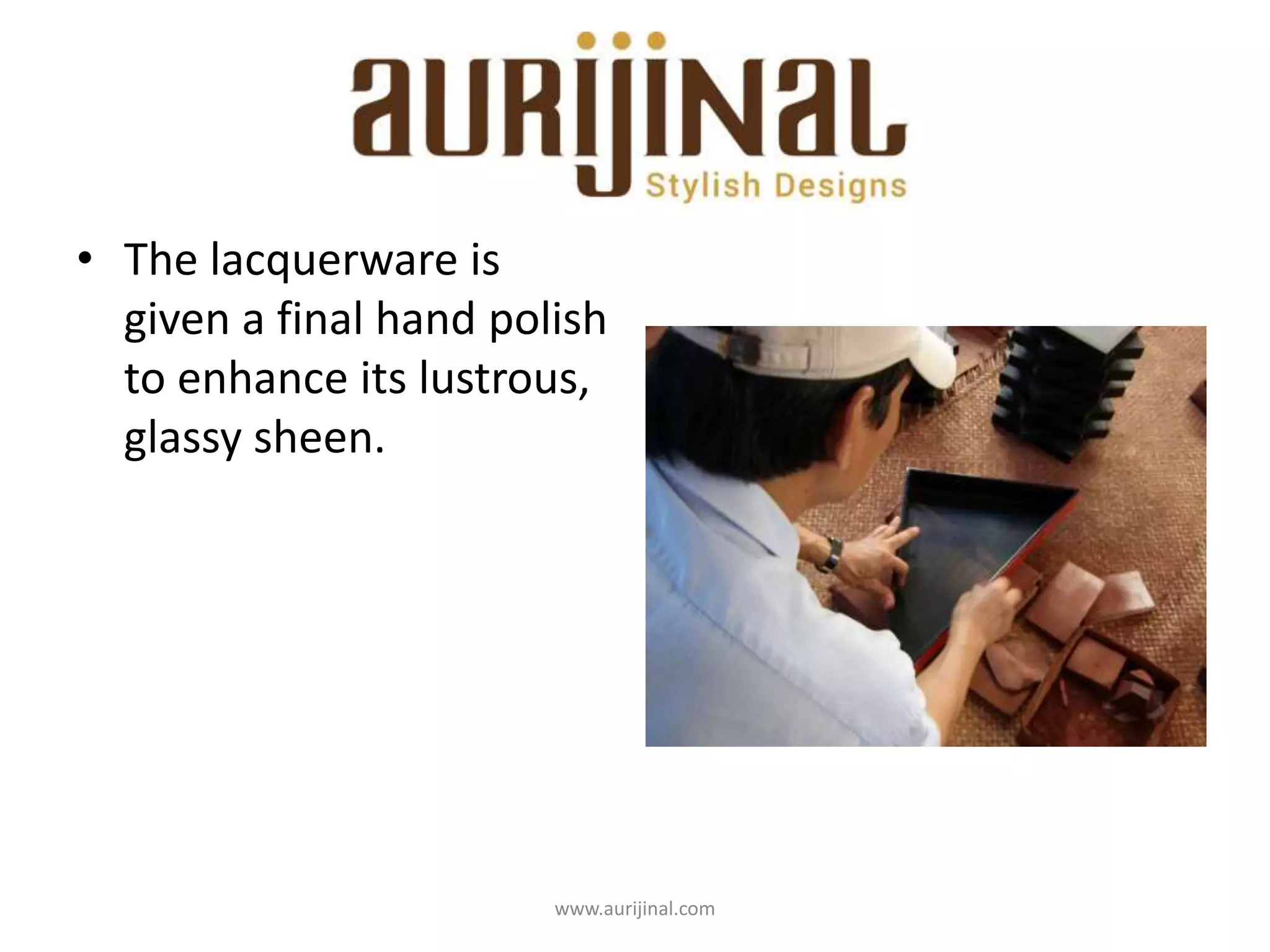

The document outlines the intricate traditional Vietnamese lacquerware process, which can take up to 4 months to complete a single piece, with even simple items requiring a minimum of 75 days. The process includes multiple stages of sealing, coating, sanding, and applying lacquer, followed by a final hand polish for a glassy sheen. Each item is made with care, involving meticulous techniques such as the application of broken eggshell before applying multiple coats of lacquer.