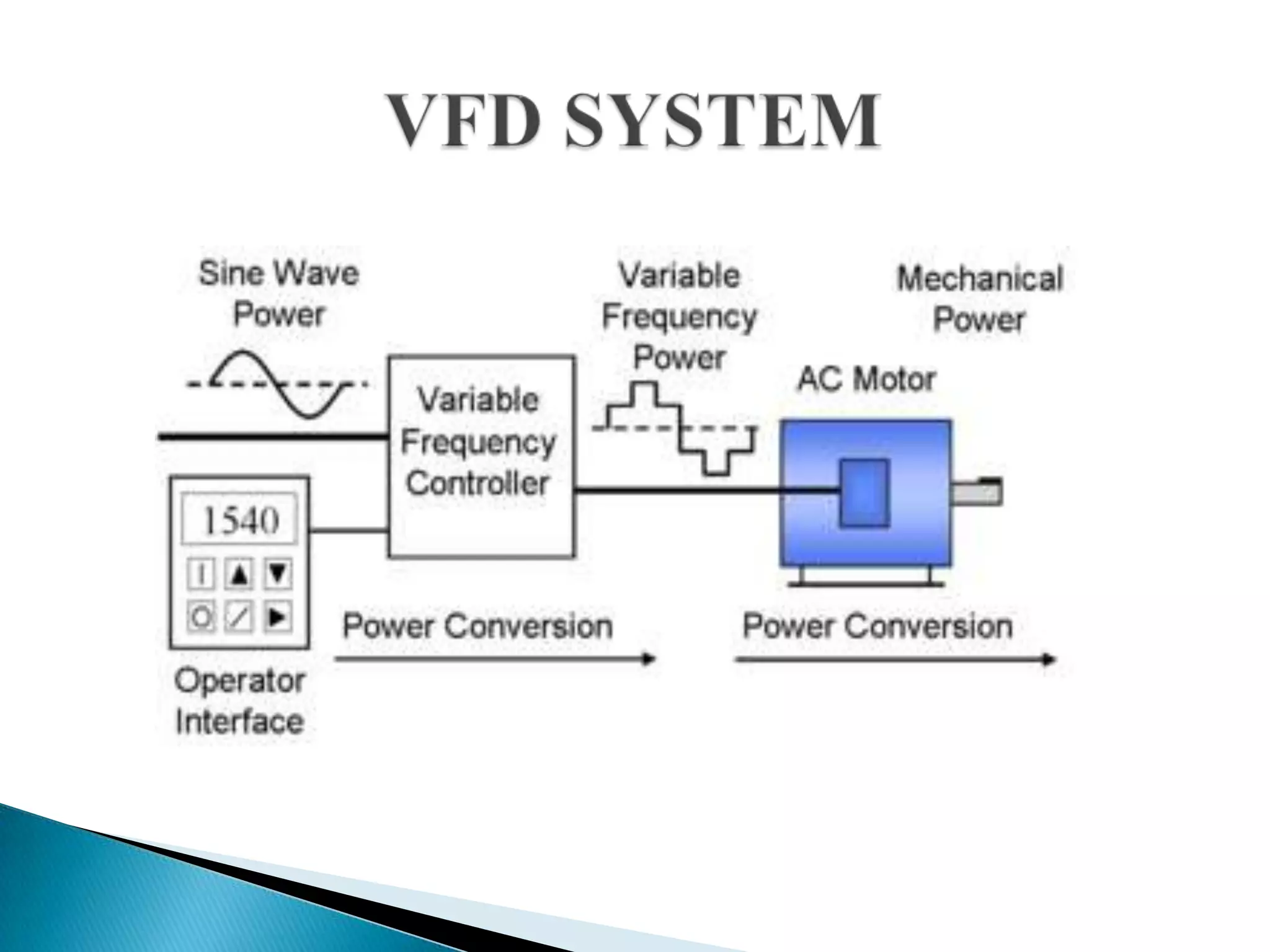

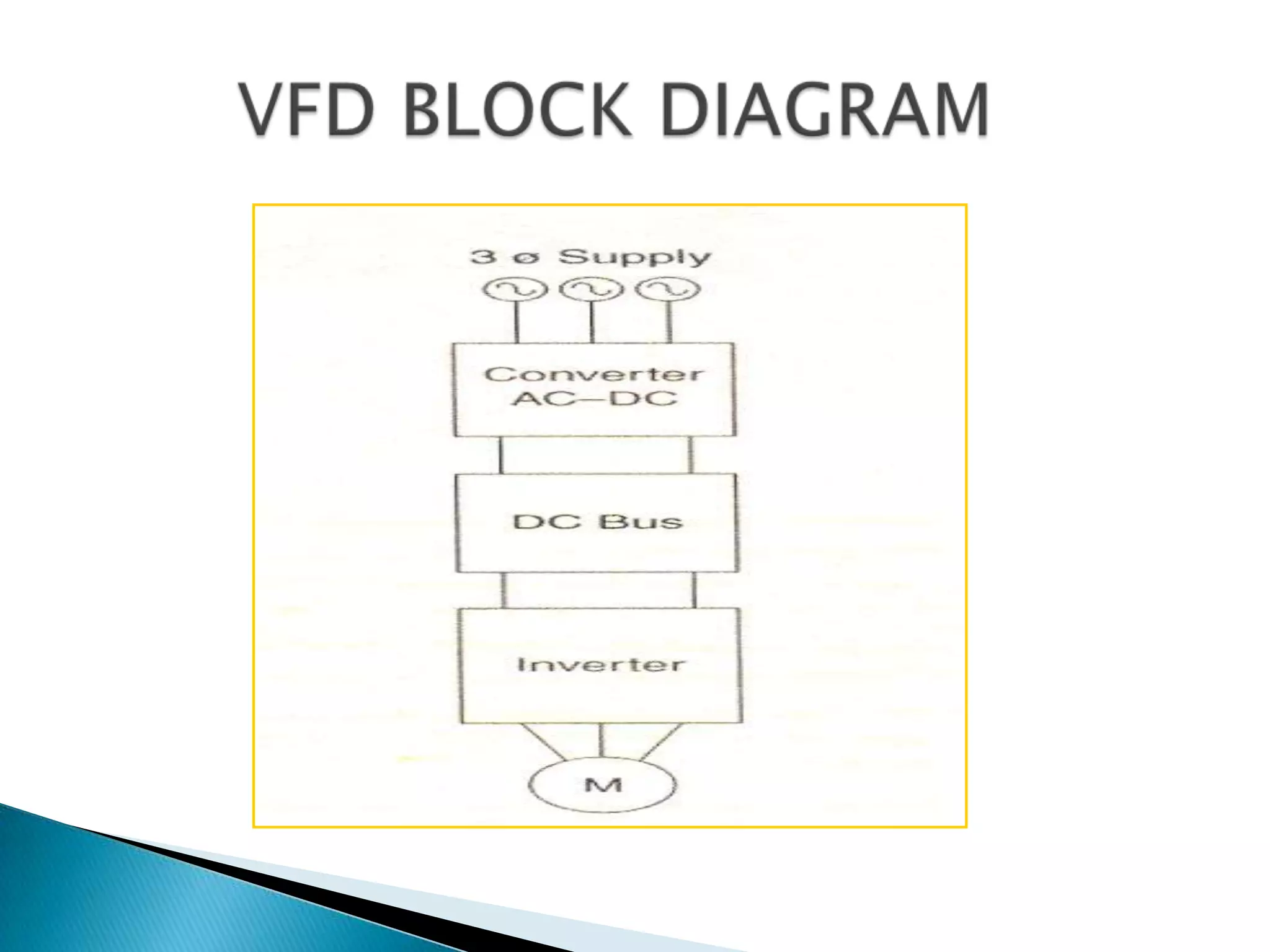

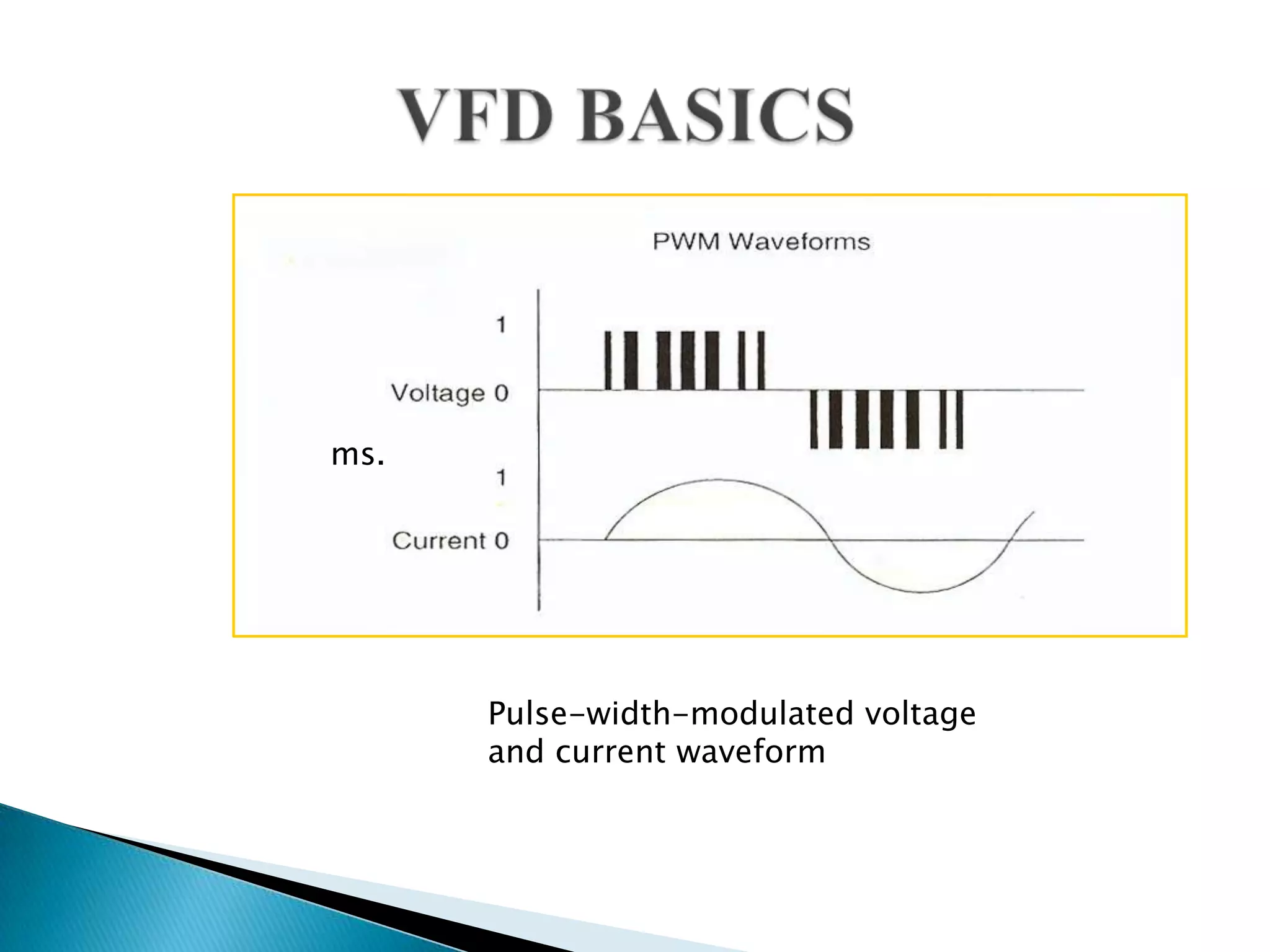

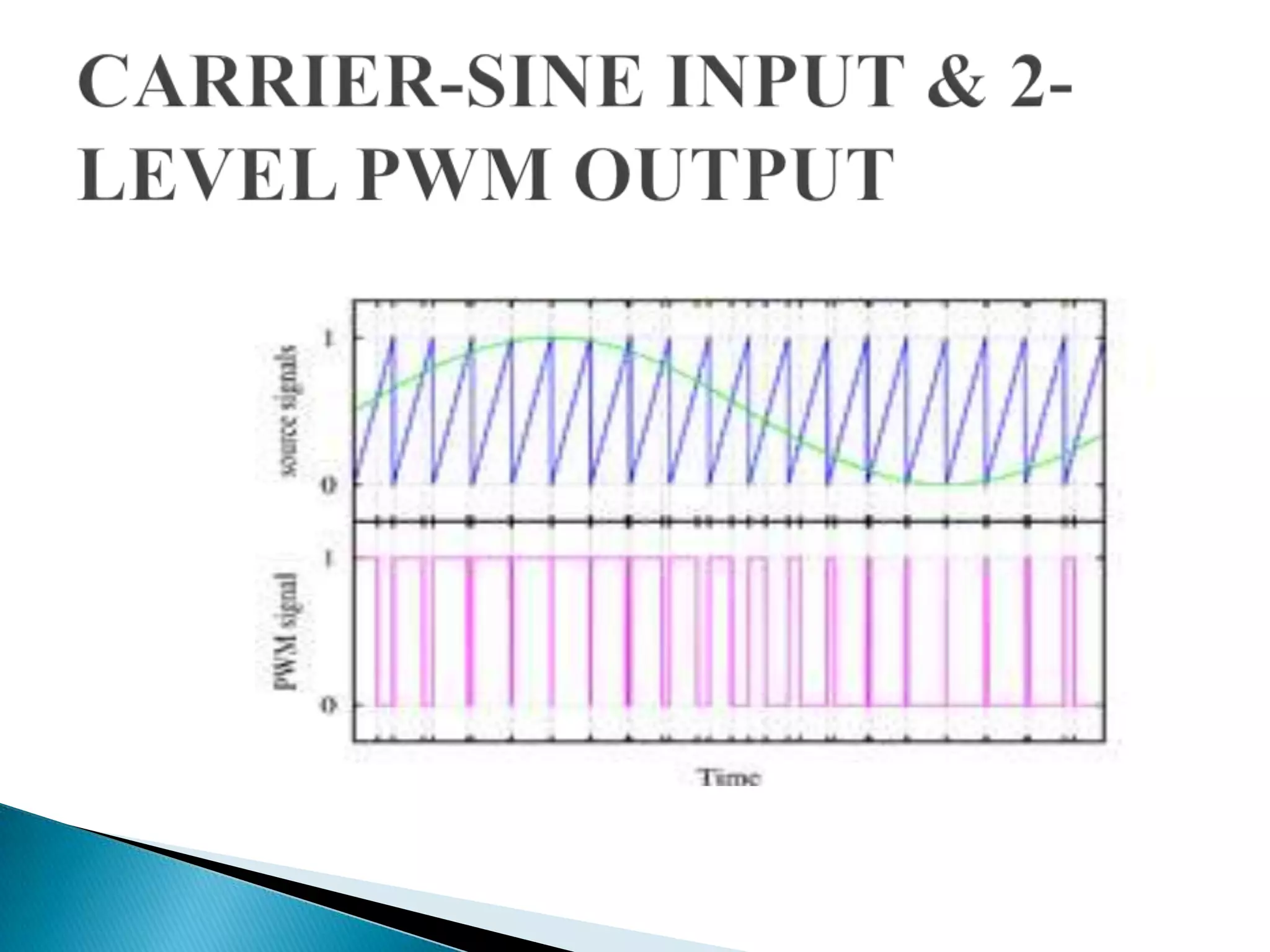

Variable frequency drives (VFDs) are used to control the speed of AC induction motors by varying the frequency of the power supplied to the motor. A VFD system consists of an AC motor, controller, and operator interface. VFDs allow motors to operate at multiple speeds by adjusting the frequency of the power supplied. They provide benefits like energy savings, protection from overloads, and safe acceleration and deceleration of motors. Common applications of VFDs include controlling pumps, fans, conveyors, and compressors.