Recommended

PDF

Artificial Intelligence, Data and Competition – SCHREPEL – June 2024 OECD dis...

PDF

How to Leverage AI to Boost Employee Wellness - Lydia Di Francesco - SocialHR...

PDF

Storytelling For The Web: Integrate Storytelling in your Design Process

PDF

2024 State of Marketing Report – by Hubspot

PDF

2024 Trend Updates: What Really Works In SEO & Content Marketing

PDF

Everything You Need To Know About ChatGPT

PDF

Product Design Trends in 2024 | Teenage Engineerings

PPTX

INDUSTRIAL MICROBIOLOGY-1.pptx HDENDFHEK

PPTX

Arrthymias in cardiology for Physician assistant

PDF

Understanding Hair Loss: Causes, Solutions, and Healthy Hair Strategies

PPTX

Nursing process.pptx nursing management.

PDF

11.Biological Oxidation.pdf In Pharmacy In Science

PPTX

PPT presentation on Gairikadya malaahara

PPTX

Online Personal Yoga Training certificate course .pptx

PPTX

50 Hrs - Yoga & Dialectical Behaviour Therapy (YDBT) Teacher Training Certifi...

PPTX

سلاید التراسوند.pptxسلاید التراسوندسلاید التراسوند

PPTX

DIABETIC RETINOPATHY DIABETIC RETINOPATHY

PPTX

SONIC AND ULTRASONIC INSTRUMENTS PERIO.pptx

PPTX

Seniors Chair Yoga Teacher Training Certificate Course.pptx

PDF

A Brief Introduction About - Antonial Marbuery Cleveland Ohio

PPTX

Pulmonary TB by Rakhi Rana.pptx for medical and nursing students

PPTX

Yoga for Cancer Teacher Training Program Overview.pptx

PDF

“Process and Importance of Hospital Planning”

PPTX

Chronic Reproductive Health Condition (2).pptx

PPTX

Heart Block ppt made by 1sy year NH student

PPTX

Dhatu_dhatu_mala_Presentation_BAMS_1st_proff.pptx

PDF

Ocular Health Evaluation with Retinal Imaging (Optomap)

PPTX

Adolescent reproductive Health slide4.pptx

PDF

How Race, Age and Gender Shape Attitudes Towards Mental Health

PDF

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

More Related Content

PDF

Artificial Intelligence, Data and Competition – SCHREPEL – June 2024 OECD dis...

PDF

How to Leverage AI to Boost Employee Wellness - Lydia Di Francesco - SocialHR...

PDF

Storytelling For The Web: Integrate Storytelling in your Design Process

PDF

2024 State of Marketing Report – by Hubspot

PDF

2024 Trend Updates: What Really Works In SEO & Content Marketing

PDF

Everything You Need To Know About ChatGPT

PDF

Product Design Trends in 2024 | Teenage Engineerings

PPTX

INDUSTRIAL MICROBIOLOGY-1.pptx HDENDFHEK

Recently uploaded

PPTX

Arrthymias in cardiology for Physician assistant

PDF

Understanding Hair Loss: Causes, Solutions, and Healthy Hair Strategies

PPTX

Nursing process.pptx nursing management.

PDF

11.Biological Oxidation.pdf In Pharmacy In Science

PPTX

PPT presentation on Gairikadya malaahara

PPTX

Online Personal Yoga Training certificate course .pptx

PPTX

50 Hrs - Yoga & Dialectical Behaviour Therapy (YDBT) Teacher Training Certifi...

PPTX

سلاید التراسوند.pptxسلاید التراسوندسلاید التراسوند

PPTX

DIABETIC RETINOPATHY DIABETIC RETINOPATHY

PPTX

SONIC AND ULTRASONIC INSTRUMENTS PERIO.pptx

PPTX

Seniors Chair Yoga Teacher Training Certificate Course.pptx

PDF

A Brief Introduction About - Antonial Marbuery Cleveland Ohio

PPTX

Pulmonary TB by Rakhi Rana.pptx for medical and nursing students

PPTX

Yoga for Cancer Teacher Training Program Overview.pptx

PDF

“Process and Importance of Hospital Planning”

PPTX

Chronic Reproductive Health Condition (2).pptx

PPTX

Heart Block ppt made by 1sy year NH student

PPTX

Dhatu_dhatu_mala_Presentation_BAMS_1st_proff.pptx

PDF

Ocular Health Evaluation with Retinal Imaging (Optomap)

PPTX

Adolescent reproductive Health slide4.pptx

Featured

PDF

How Race, Age and Gender Shape Attitudes Towards Mental Health

PDF

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

PDF

PDF

PEPSICO Presentation to CAGNY Conference Feb 2024

PDF

Content Methodology: A Best Practices Report (Webinar)

PPTX

How to Prepare For a Successful Job Search for 2024

PDF

Social Media Marketing Trends 2024 // The Global Indie Insights

PDF

Trends In Paid Search: Navigating The Digital Landscape In 2024

PDF

5 Public speaking tips from TED - Visualized summary

PDF

ChatGPT and the Future of Work - Clark Boyd

PDF

Getting into the tech field. what next

PDF

Google's Just Not That Into You: Understanding Core Updates & Search Intent

PDF

How to have difficult conversations

PDF

Introduction to Data Science

PDF

Time Management & Productivity - Best Practices

PDF

The six step guide to practical project management

PDF

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

PDF

Unlocking the Power of ChatGPT and AI in Testing - A Real-World Look, present...

PDF

12 Ways to Increase Your Influence at Work

PDF

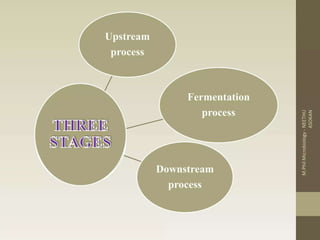

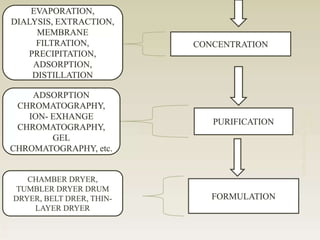

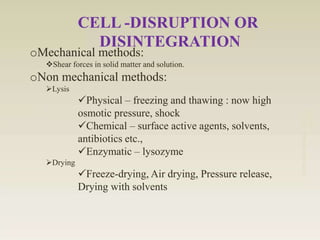

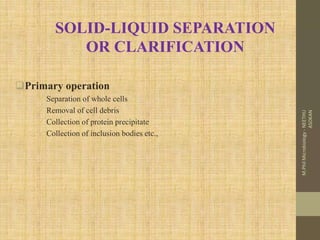

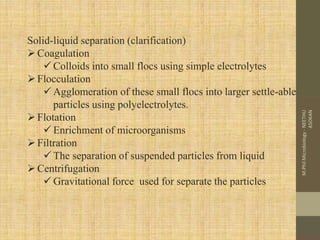

Upstream and Downstream Processing-1.pptx 9. UPSTREAM PROCESS

• Upstream processing in industrial

microbiology encompasses the initial steps of

biomanufacturing, focusing on microorganism

selection, genetic improvement, media formulation,

and cultivation in bioreactors to maximize product

yield.

• It involves developing an active inoculum, sterilizing,

and optimizing growth conditions (pH, temperature,

oxygen) to produce high-quality biomass or

metabolites.

10. Steps:

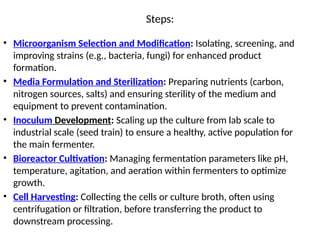

• Microorganism Selection and Modification: Isolating, screening, and

improving strains (e.g., bacteria, fungi) for enhanced product

formation.

• Media Formulation and Sterilization: Preparing nutrients (carbon,

nitrogen sources, salts) and ensuring sterility of the medium and

equipment to prevent contamination.

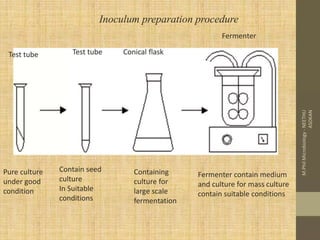

• Inoculum Development: Scaling up the culture from lab scale to

industrial scale (seed train) to ensure a healthy, active population for

the main fermenter.

• Bioreactor Cultivation: Managing fermentation parameters like pH,

temperature, agitation, and aeration within fermenters to optimize

growth.

• Cell Harvesting: Collecting the cells or culture broth, often using

centrifugation or filtration, before transferring the product to

downstream processing.