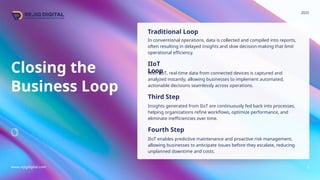

Industrial IoT (IIoT) is reshaping how enterprises achieve digital transformation. By integrating connected sensors, devices, and analytics across the business loop, organizations can streamline operations, enhance decision-making, and drive sustainable growth. This article by Rejig Digital explores how IIoT enables real-time insights, predictive intelligence, and automation to optimize every stage of the business cycle.

📊 What You’ll Discover:

✔️ Business Loop Optimization: How IIoT connects operations, supply chains, and customer experience for seamless workflows.

✔️ Real-Time Insights: Leveraging sensor data and analytics to make faster, data-driven decisions.

✔️ Predictive & Smart Operations: Anticipating challenges, reducing downtime, and improving efficiency.

✔️ Technology Drivers: AI, edge computing, 5G networks, and secure IIoT systems powering transformation.

✔️ Future-Ready Enterprises: Building agile, resilient, and competitive organizations through IIoT integration.

⚙️ From smarter operations to enhanced ROI, optimizing the business loop with IIoT is no longer optional—it’s a strategic imperative for Industry 4.0 enterprises.

🚀 Partner with Rejig Digital to implement IIoT solutions that drive efficiency, connectivity, and sustainable growth across your enterprise.