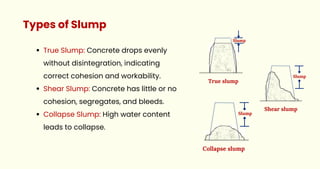

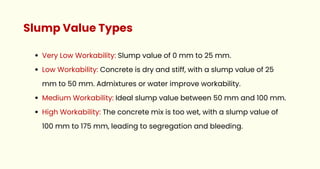

The document explains the concrete slump test used by civil consultants to evaluate the consistency and workability of concrete. It details the testing procedure, types of slump (true, shear, and collapse), and corresponding slump values that indicate different levels of workability. Factors affecting workability include water content, mix proportions, aggregate size, surface texture, and the use of admixtures.