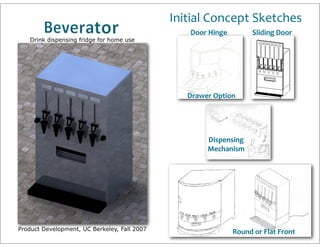

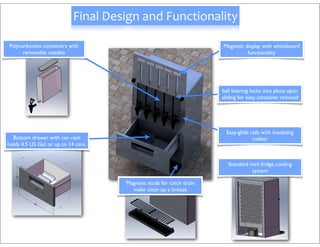

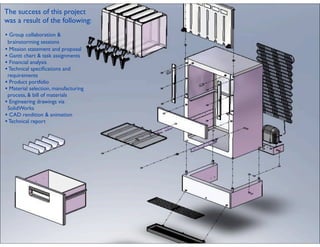

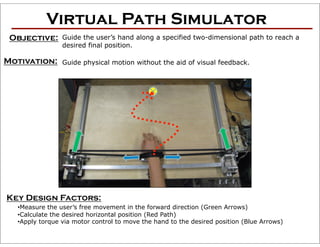

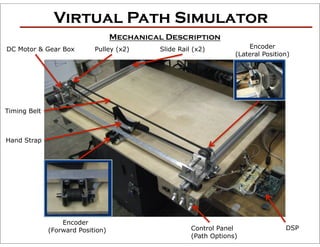

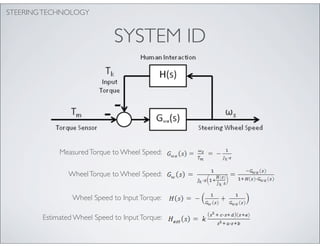

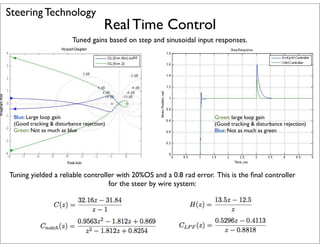

Kevin Lomeli restored a clunker car as a teenager, sparking his interest in mechanical engineering. In college, he worked on several engineering projects including designing a drink dispensing fridge called the Beverator. He also worked on a virtual path simulator and steering technology projects. After graduating, he assisted UC Berkeley research groups by designing camera mounts for small aircraft and UAV server racks. He has experience in mechanical design, product development, control systems, and unmanned aircraft technology.