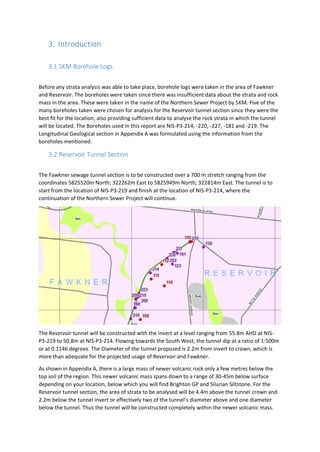

The document discusses a proposed 700m sewage tunnel connecting the Reservoir and Fawkner areas of Melbourne to the Northern Diversion Sewer. It analyzes borehole logs from the area to characterize the basalt rock mass where the tunnel will be constructed. Classification systems like the Rock Mass Rating and Q System are used to evaluate parameters like rock strength, discontinuity spacing and condition, and groundwater, in order to assess the rock mass and inform construction recommendations.