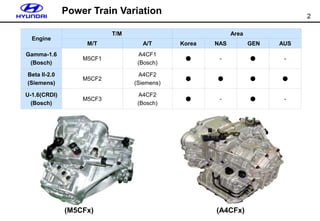

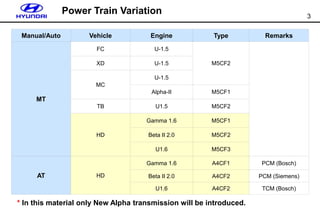

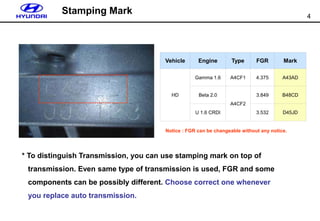

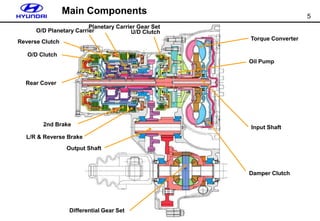

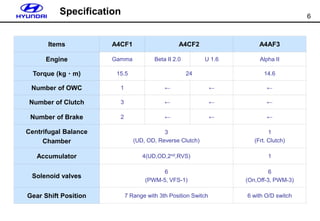

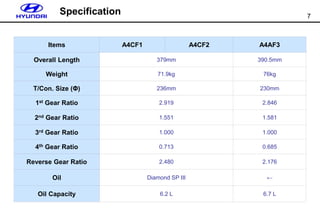

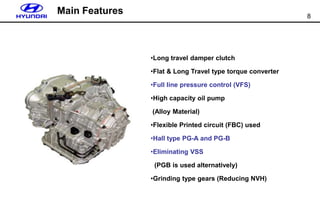

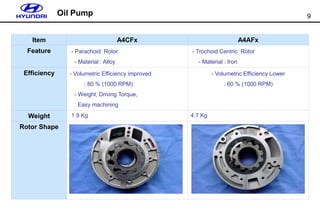

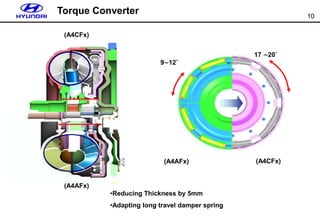

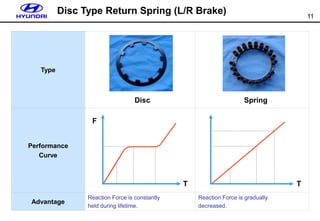

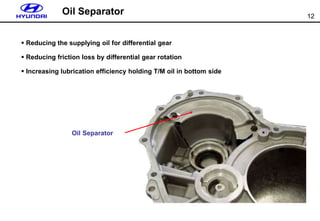

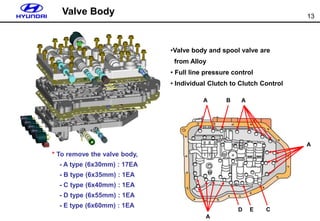

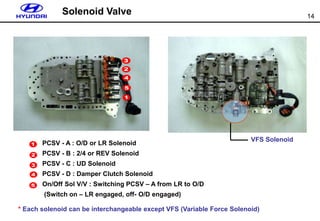

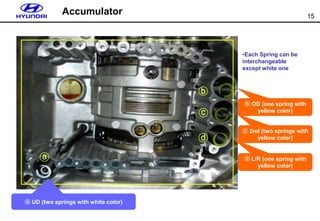

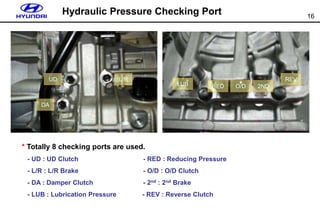

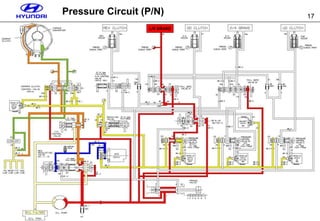

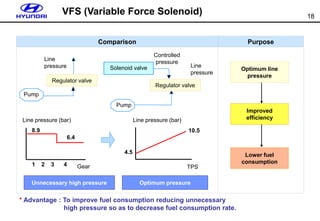

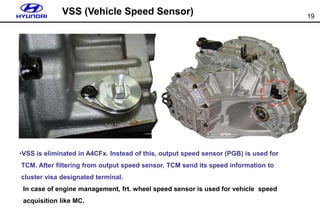

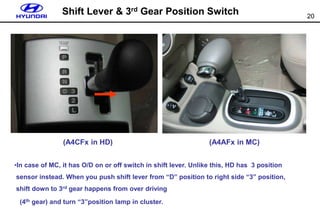

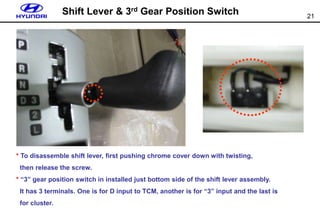

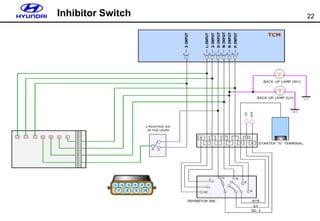

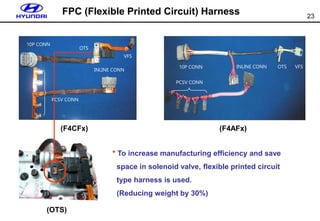

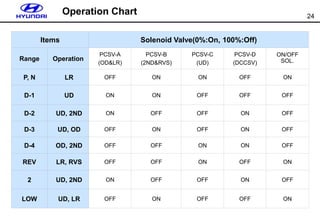

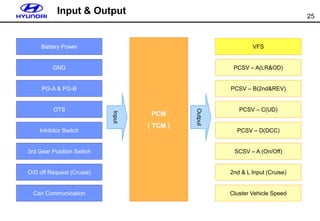

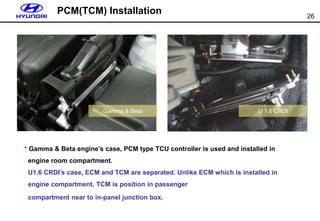

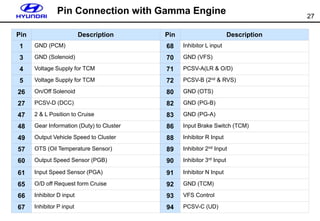

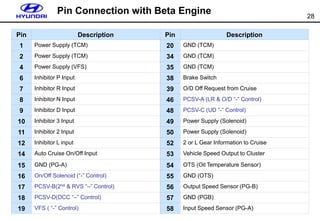

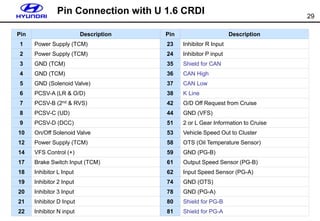

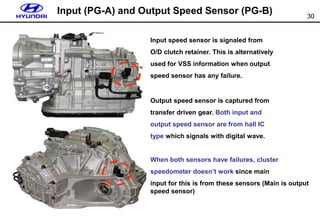

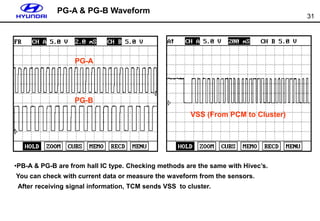

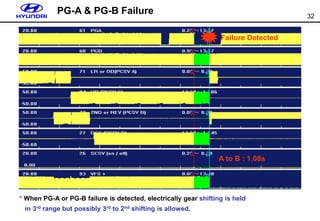

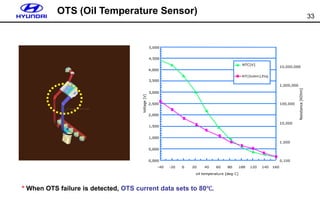

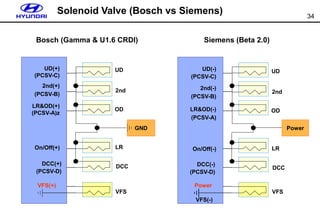

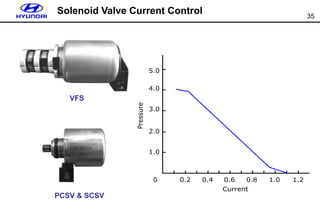

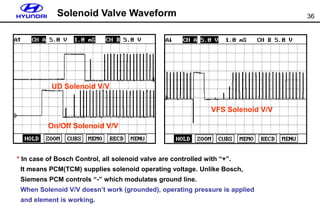

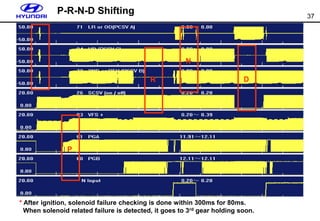

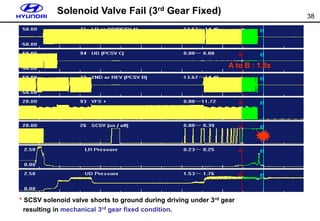

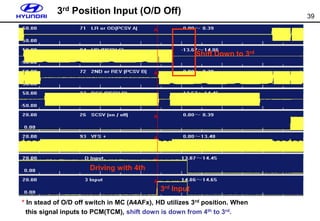

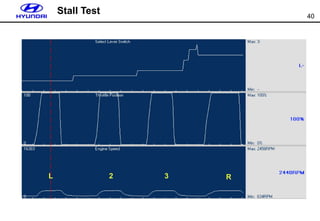

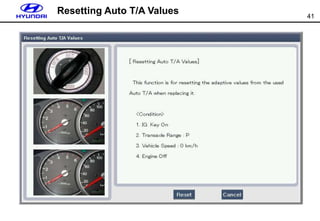

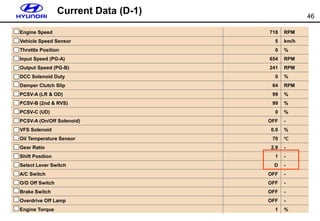

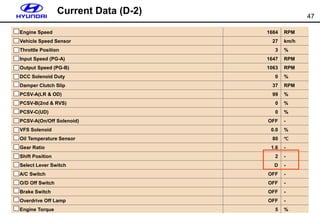

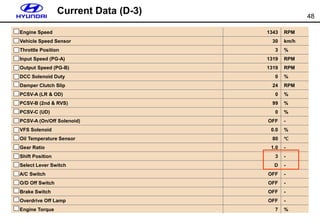

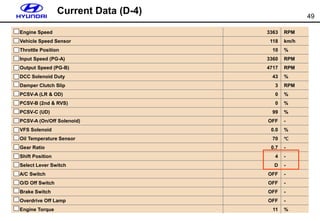

The document describes the specifications and features of the new A4CFX transmission system, highlighting variations of the engine and transmission configurations offered. Key components, operational mechanics, and system efficiencies are detailed, including the role of solenoid valves, oil capacity, and gear ratios. Additionally, it outlines wiring connections, solenoid operation, and diagnostic protocols for maintenance and troubleshooting.